Why Does a Perforated Metal Plate Deform? In-Depth Analysis of Causes and Solutions

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 16:55:08 Browse:

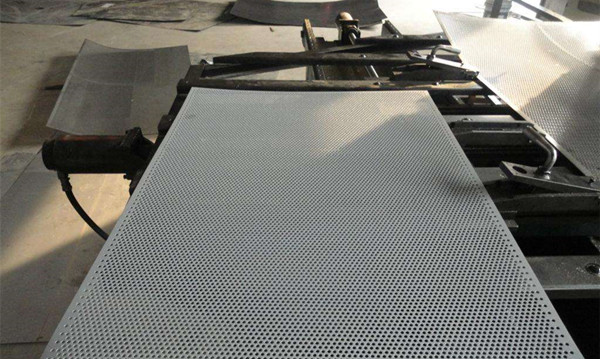

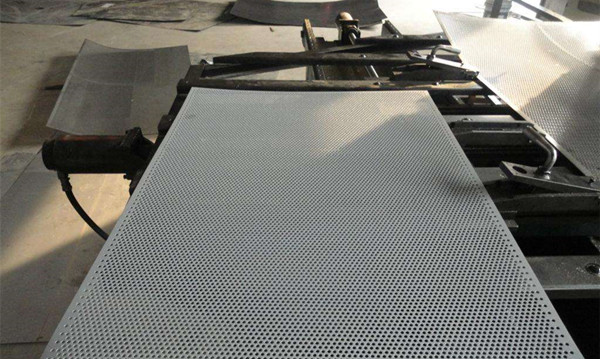

Perforated metal plates are widely used in various industries, including architectural decoration, filtration, ventilation, and protective enclosures. However, during the production process, it’s common to notice that the final perforated sheets are not as flat as the original raw material. They may exhibit noticeable warping or deformation, which affects both the appearance and the practical installation. So, why do perforated metal plates deform after punching? Here, Anping Senchi Perforated Plate Factory provides a comprehensive analysis of the main causes and how to address them effectively.

1. Deformation Caused by the Manufacturing Process

Perforated metal plates are usually produced using CNC punching machines. During this process, alloy punching pins strike the raw metal sheet repeatedly to create holes based on a specific pattern. When the punch pin contacts the sheet, a significant amount of heat is generated in the punching area, while the surrounding metal remains cooler. This uneven thermal distribution creates a thermal shock, similar to an annealing effect. As the punched area rapidly cools, the hardness of the sheet increases locally, and internal stresses develop, ultimately resulting in deformation.

In addition, the punching process disrupts the grain structure of the metal, disturbing its original stress balance. This imbalance is a major contributing factor to plate warping.

2. Influence of Raw Material Properties

The degree of deformation in a perforated metal plate is closely related to the type of material used. Different metals have varying levels of ductility, hardness, and thermal conductivity—all of which influence how a sheet reacts under the stress of punching.

In general:

Aluminum perforated plates deform the least, as aluminum is softer and more ductile, allowing it to better absorb and redistribute stress.

3. Impact of Hole Diameter and Hole Spacing

Hole design is another critical factor influencing deformation in perforated metal plates. The diameter of the holes and the spacing between them directly affect the structural integrity of the sheet.

Smaller hole diameters and tighter spacing increase the number of perforations per unit area, creating higher localized stress zones and a greater tendency for deformation.

Larger holes with wider spacing reduce concentrated stress and help maintain flatness.

Proper hole layout not only improves strength and performance but also enhances overall cost-effectiveness during production.

4. Edge Margin Design Matters

The edge margin—or the distance between the edge of the sheet and the nearest row of holes—plays an important role in minimizing deformation. If the edge margin is too narrow, stress is concentrated at the edges, often causing curling or warping. Conversely, overly wide margins may lead to central buckling due to uneven force distribution.

Therefore, thoughtful design of edge margins in coordination with the punching pattern is essential to reduce deformation risk and ensure product stability.

5. How to Effectively Minimize Deformation in Perforated Metal Plates?

To reduce the chances of deformation and improve the quality and stability of perforated metal products, consider the following recommendations:

Optimize Punching Tool Path and Sequence

Design a strategic punching order to distribute forces evenly and reduce thermal buildup.

Choose Suitable Materials and Sheet Thickness

Select materials with better ductility for the application and consider increasing sheet thickness to improve rigidity.

Adjust Hole Layout

Use staggered or diagonal hole arrangements to distribute stress more evenly across the plate.

Apply Post-Punching Treatments

Annealing or leveling the sheet after punching can effectively relieve internal stress and restore flatness.

Ensure Adequate Edge Margin

Maintain reasonable edge distances to prevent stress concentration at borders and corners.

Conclusion

Perforated metal plate deformation is a multi-factor issue involving material selection, hole design, manufacturing processes, and post-processing techniques. By fully understanding these influencing elements, manufacturers can take proactive measures to reduce warping and improve the final product's durability, performance, and aesthetic appeal.

If you encounter any issues related to the production or use of perforated metal sheets, Anping Senchi Perforated Plate Factory is here to offer professional solutions and high-quality products tailored to your needs.