Perforated panels are widely used in architectural, decorative, and industrial applications due to their unique structure and functionality. Among various surface treatment methods, spray coating stands out as a preferred option, offering a range of advantages in both performance and appearance. Below, we explore the key benefits of using spray coating on perforated panels.

1. Enhanced Aesthetics

Wide Range of Colors

Spray coating provides a rich palette of color choices to match diverse design styles. Whether you prefer modern minimalism or classic elegance, spray coating can achieve the desired visual effect.

Improved Surface Finish

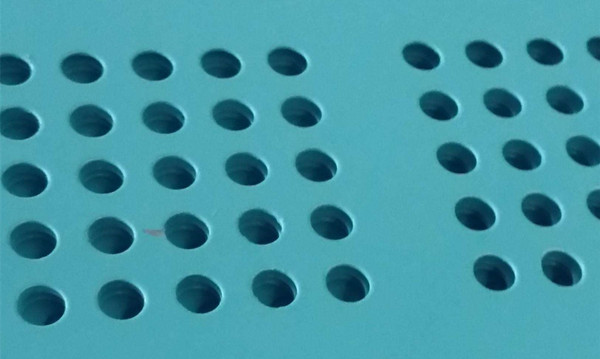

Sprayed perforated panels exhibit smoother surfaces and uniform color distribution, enhancing their overall visual appeal. The coating adds gloss and texture, especially under lighting.

Creative Design Possibilities

With spray coating, it's possible to incorporate printed patterns or textured finishes. For example, wood grain or stone-like textures can be achieved, adding natural beauty to the panels.

2. Superior Corrosion Resistance

Rust and Corrosion Protection

Spray coating forms a protective layer on the surface of perforated panels, effectively preventing rust and corrosion caused by moisture and air exposure. This is especially important for panels used in harsh environments.

Extended Lifespan

Using high-quality anti-corrosion coatings such as fluorocarbon paint significantly extends the lifespan of perforated panels, making them suitable for outdoor applications.

Easy Spot Repairs

If the surface of a perforated panel becomes scratched or damaged, it can be easily restored through localized spray recoating, maintaining both appearance and protection.

3. High Versatility

Applicable to Multiple Materials

Spray coating is suitable not only for metal perforated panels (such as aluminum or steel) but also for non-metal panels like plastic or fiberglass.

Adapts to Complex Shapes

Even panels with intricate shapes or fine perforations can be evenly coated with the right spray equipment and parameters.

Efficient Application Process

Spray coating is quick and simple to apply, making it ideal for large-scale production or on-site installation. It saves both time and labor costs.

4. Cost-Effective

Affordable and Practical

Compared to other treatments like galvanization or powder coating, spray coating is generally more affordable, especially when using standard paints. It offers excellent value for money.

Low Maintenance Costs

Thanks to its corrosion resistance, spray-coated perforated panels require less long-term maintenance, which is beneficial in damp or outdoor environments.

Reusability

When the coating fades or deteriorates, panels can be refreshed with a new spray coat instead of replacing the entire panel—making it both economical and eco-friendly.

5. Convenient Application

Simple Process

The spray coating process is straightforward: surface cleaning, sanding, spraying, and curing. Even non-professionals can carry out basic spray jobs under proper guidance.

Ideal for On-Site Work

Spray coating can be performed not only in factories but also on construction sites, making it perfect for real-time adjustments during installation.

Fast Drying

Modern quick-dry coatings allow the surface to cure in a short time, reducing downtime and boosting project efficiency.

6. Environmentally Friendly

Eco-Friendly Coatings Available

With rising environmental awareness, spray coatings increasingly use eco-friendly formulations free from heavy metals or harmful substances, supporting sustainable development and green construction goals.

Conclusion

Spray coating offers significant advantages in improving the aesthetics, durability, versatility, and cost-efficiency of perforated panels. For projects that demand both high performance and economic value, spray coating is an optimal surface treatment solution.