Perforated Aluminum Sheet Specifications and Applications | Custom Aluminum Perforated Panels

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-27 11:14:39 Browse:

Material Selection Range

Perforated aluminum sheets offer a wide range of material options, allowing customization based on project requirements. Common thickness categories include:

Thin Sheets (0.5mm–1.0mm): Suitable for interior decoration and acoustic panels where weight reduction is key.

Medium Thickness Sheets (1.0mm–5.0mm): Widely used in architectural decoration and acoustic engineering.

Thick Sheets (5.0mm–20mm): Ideal for industrial equipment casings and outdoor structures requiring higher strength and durability.

The most commonly used materials are aluminum alloys such as 3003 and 5052, known for their excellent corrosion resistance and workability.

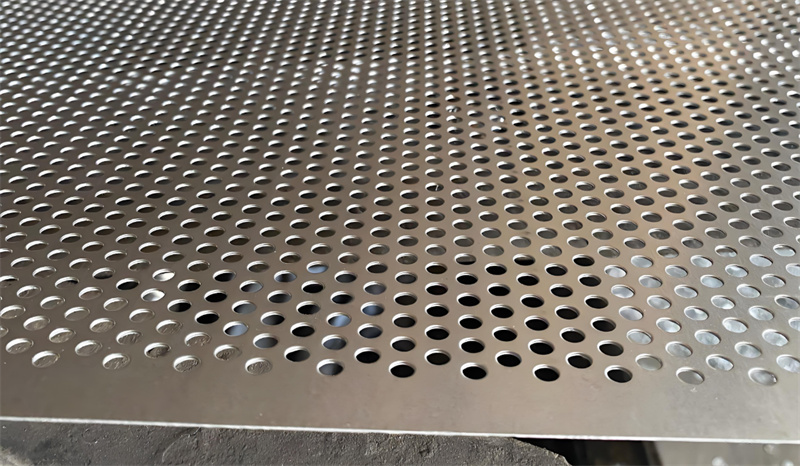

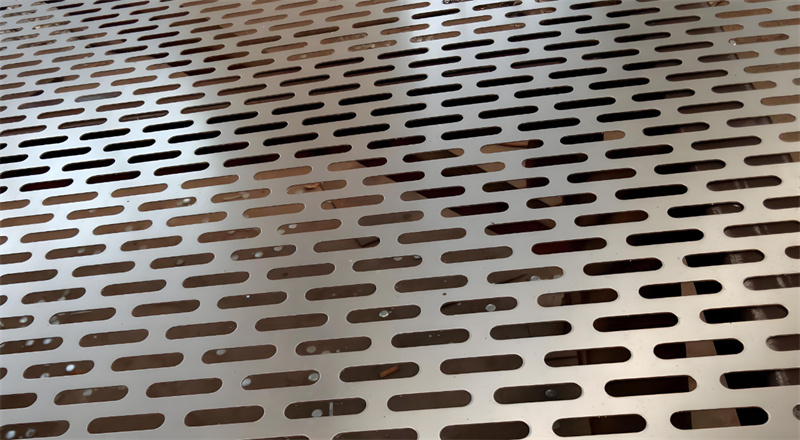

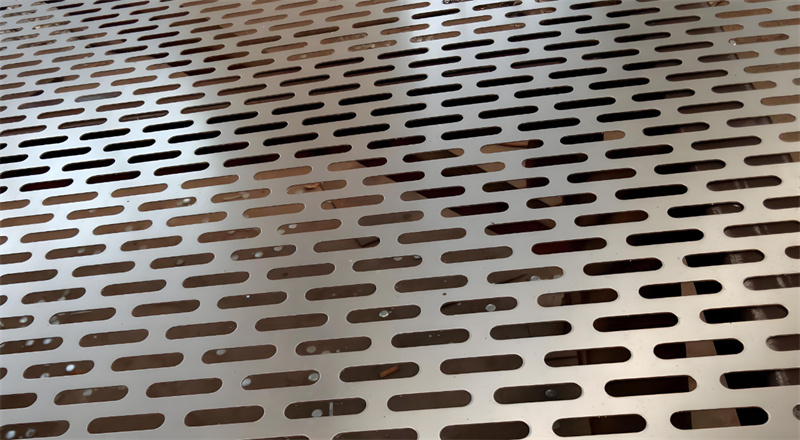

Hole Type Classification

Perforated aluminum panels are available in a wide variety of hole types to meet diverse design needs:

Standard Hole Types: Round holes, slotted holes, square holes, rectangular holes, triangular holes, hexagonal holes, cross holes, plum blossom holes, diamond holes, etc.

Special Hole Types: Pentagram holes, safety grille holes, raised round holes, louver holes, fish scale holes, etc.

Custom Hole Types: Fully customizable based on customer-provided drawings or samples.

Size Specifications

Perforated aluminum sheets come in flexible dimensions tailored to specific project requirements:

Standard Widths: Raw material widths typically include 1000mm, 1200mm, and 1500mm.

Custom Lengths: Lengths can be freely adjusted to match various application needs.

Trimming Services: If standard widths do not suffice, cutting services are available to reach the desired size.

Non-Standard Dimensions: Fully customizable production available upon request.

Application Fields

Thanks to their performance and versatility, perforated aluminum sheets are widely applied in several industries:

Architectural Decoration: Used for wall cladding, ceiling acoustic panels, partitions, etc. Typical thickness: 1.0mm–3.0mm, with hole diameters between 8mm–15mm.

Acoustic Engineering: Applied in recording studios, conference rooms, and concert halls for sound absorption. Typical thickness: 1.5mm–2.0mm, hole diameters between 10mm–20mm.

Industrial Equipment: Used for machine casings, ventilation ducts, and heat exchangers. Typical thickness: 2.0mm–5.0mm, hole diameters between 5mm–15mm.

Outdoor Decoration: Ideal for sunshades, guardrails, and outdoor signage. Typical thickness: 3.0mm–10mm, hole diameters between 10mm–20mm.

Key Advantages

Diverse Options: A wide variety of specifications and models available to suit different needs.

High Strength & Durability: Made from aluminum alloy, offering excellent mechanical properties and corrosion resistance.

Superior Acoustic Performance: Various hole sizes and spacing options deliver outstanding sound absorption.

Eco-Friendly & Recyclable: Aluminum is 100% recyclable, making it a sustainable choice.

Flexible Surface Treatments: Anodizing, powder coating, and painting options enhance both aesthetics and durability.

If you're looking for more information or need customized solutions for perforated aluminum sheets, feel free to visit our official website or contact our customer support team—we're here to help!