1. Lightweight, High Strength, and Corrosion Resistance

Perforated Aluminum Sheets are made from aluminum plates ranging in thickness from 0.5mm to 20mm, processed using precision stamping molds. Aluminum naturally offers excellent mechanical properties, particularly in terms of strength. Its oxide layer provides strong corrosion resistance, making it suitable for use in exterior walls, signage, ventilation systems, and more.

2. Excellent Workability and Formability

Perforated Aluminum Sheets exhibit superior ductility and can undergo a variety of surface treatments such as powder coating, anodizing, polishing, and electrophoresis. The material is easy to cut, bend, and punch, supporting diverse architectural and industrial design requirements.

3. Multiple Surface Treatment Options

Surface treatments for Perforated Aluminum Sheets include electrostatic powder coating, PVDF coating, and anodizing. These treatments enhance aesthetic appeal while improving weather resistance and anti-fouling properties, making them suitable for both indoor and outdoor applications.

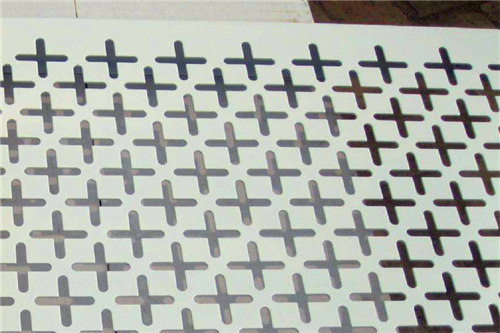

4. Outstanding Filtration and Ventilation Capabilities

Perforated Aluminum Sheets are available in various hole shapes—round, oval, slot, square, and triangular. Hole sizes and spacing can be customized to meet specific needs. These perforations offer excellent air circulation while preventing the entry of unwanted debris, making them ideal for air purification systems, ventilation ducts, and automotive exhaust components.