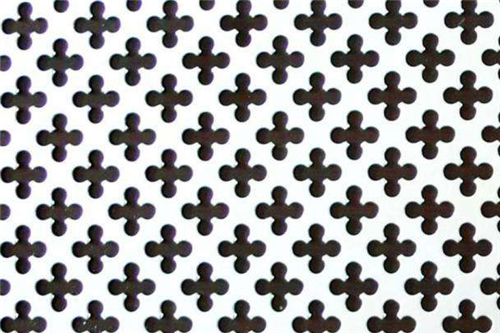

Perforated aluminum sheets are manufactured by punching precise holes into aluminum plates ranging in thickness from 0.5mm to 20mm, using advanced CNC punching machines and specialized dies. Thanks to their unique perforation patterns and excellent physical properties, perforated aluminum sheets are widely applied across multiple industries. These sheets can be customized with various hole shapes—such as round, oval, slotted, square, rectangular, triangular, pentagonal, hexagonal, diamond, cross-shaped, plum blossom, rhomboid, fish scale, louver, raised round, and crocodile mouth holes. In addition, both the hole diameter and spacing can be flexibly tailored to suit different design and functional requirements, making them extremely versatile.

1. Industrial Equipment and Machinery

In chemical, pharmaceutical, and mining machinery, perforated aluminum panels are frequently used for filter screens, crusher bases, ventilation parts, and more. Due to aluminum’s inherent corrosion resistance and structural strength, these sheets perform reliably even in high-temperature, high-corrosion industrial environments. They are capable of withstanding substantial pressure and are ideal for scenarios requiring efficient filtering, separation, and airflow control.

2. Applications in Architecture and Interior Design

Lightweight, aesthetically pleasing, and durable, aluminum perforated sheets are a popular choice in modern architectural projects. They are widely used for ceiling tiles, façade cladding, interior and exterior mesh panels, ventilation partitions, stair railings, and other decorative structures. These sheets not only provide visual enhancement but also offer functional benefits like natural ventilation, light diffusion, moisture resistance, and sun shading.

Their excellent anti-rust properties make them especially suitable for humid environments, such as coastal areas. Common architectural applications include balcony screens, ventilation ducts, curtain walls, and sunshades—all utilizing the multifunctional properties of perforated aluminum.

3. Public and Commercial Spaces

In commercial settings like shopping malls, airports, and exhibition halls, perforated aluminum panels serve as shelving components, display counters, ventilation grilles, anti-slip stair treads, and more. Their lightweight yet strong nature increases structural stability while reducing overall weight, making transport and installation easier.

For example, in grain storage, aluminum perforated mesh allows for excellent airflow, keeping the environment dry and extending shelf life. As anti-slip stair treads, the perforated design enhances traction and improves safety in high-traffic areas.

4. Acoustic Engineering for Noise Reduction

Few realize that perforated aluminum sheets also play a crucial role in acoustic performance. When combined with sound-absorbing materials and optimized hole design, these panels help reduce echo and suppress noise. They are widely used in public areas such as subway stations, shopping malls, cinemas, and offices to create quiet, comfortable environments.

By adjusting the size, density, and pattern of perforations, aluminum panels can be fine-tuned to meet specific acoustic requirements, making them a practical solution for sound insulation.

5. Other Diverse Applications

Beyond the sectors mentioned above, perforated aluminum panels are also employed in billboard advertising, window louvers, electronics casing, and landscape design. In outdoor signage, the perforated design reduces wind resistance while enhancing visual impact. In electronics, these sheets allow for effective heat dissipation and airflow while protecting internal components.

Urban landscapes increasingly use perforated aluminum in artistic sculptures, decorative fencing, lighting installations, and more—seamlessly combining aesthetics with practical utility.

6. Key Advantages of Perforated Aluminum Sheets

The popularity of perforated aluminum sheets stems from the following core advantages:

Lightweight & Strong: Despite being lightweight, aluminum offers excellent strength, making it easy to install while remaining durable under pressure.

Corrosion-Resistant: Aluminum naturally resists oxidation and corrosion, ideal for humid or chemically aggressive environments.

Highly Workable: Easy to cut, bend, weld, and install, perforated sheets are convenient for both manufacturers and construction teams.

Flexible Design Options: With customizable hole patterns and sizes, these sheets offer extensive design possibilities for both functional and decorative applications.

Eco-Friendly Material: Aluminum is recyclable and supports sustainable building practices in line with modern green design standards.

Conclusion

With their exceptional performance and wide-ranging adaptability, perforated aluminum sheets have become essential in fields like industrial manufacturing, modern construction, interior design, public infrastructure, and beyond. Whether used to improve equipment performance or to elevate architectural aesthetics, aluminum perforated panels continue to show unparalleled value. As technology and design demands evolve, the potential for innovative applications of perforated aluminum will only grow.