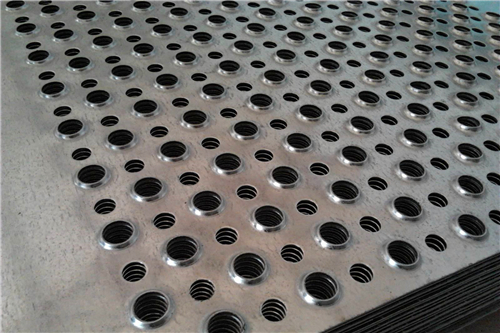

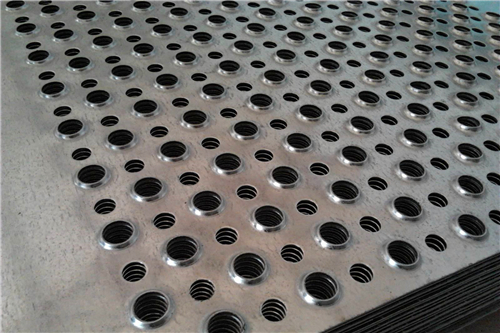

A Comprehensive Guide to Aluminum Perforated Plate Processing Techniques

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-08 11:51:49 Browse:

Aluminum perforated plates are widely used in architectural decoration, industrial manufacturing, furniture design, ventilation systems, and more, thanks to their lightweight, high strength, durability, and aesthetic appeal. To meet various functional and visual demands, aluminum perforated plates undergo multiple processing techniques. Here is a detailed overview of the most common methods used in manufacturing aluminum perforated plates and their advantages.

1. CNC Punching: Efficient and Precise Hole Customization

CNC punching machines utilize pre-programmed instructions to precisely control the punching heads on aluminum sheets, creating various hole shapes such as round, square, or oblong holes. This method is ideal for large-scale production due to its high efficiency and accuracy. It allows for flexible adjustment based on aluminum sheet thickness, meeting diverse production needs in aluminum perforated plate fabrication.

2. Shearing & Laser Cutting: Achieving Versatile Shapes

After perforation, aluminum sheets often need to be cut into specific shapes and sizes. CNC shearing machines are used for straight cuts, while laser cutting is ideal for intricate and custom patterns. Laser cutting offers smooth edges, minimal heat-affected zones, and high precision—making it perfect for personalized designs and decorative uses of aluminum perforated plates.

3. Bending & Rolling: Adding Structural Depth

Using CNC bending machines, aluminum perforated plates can be bent into various angles and curves to form components such as decorative panels or ventilation louvers. Rolling techniques can transform flat sheets into cylindrical or curved structures, commonly used in chimneys or ductwork. These processes not only enhance structural integrity but also expand design possibilities for aluminum perforated plate applications.

4. Welding: Integrating Structure with Strength

In some cases, aluminum perforated plates must be connected with other metal parts. Welding methods such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) provide strong and clean joints. These techniques enhance the stability of the overall structure while maintaining a clean aesthetic, especially in projects requiring high strength and visual appeal.

5. Surface Treatment: Improving Performance and Aesthetics

To improve corrosion resistance and visual effects, aluminum perforated plates often undergo surface treatments like anodizing, electroplating, or powder coating. Anodizing forms a protective oxide layer, while plating and coating offer diverse colors and textures. These treatments ensure that aluminum perforated plates perform well and look great in different environments and design themes.

Conclusion

Thanks to a wide range of processing techniques, aluminum perforated plates have become a versatile solution in modern architecture and industrial design. By selecting the right processing methods, manufacturers can enhance both the functionality and appearance of their products, meeting growing demand for custom and high-quality solutions. As industries evolve, aluminum perforated plates will continue to play a critical role in innovative design and structural applications.