2. Key Factors in Choosing Hole Sizes

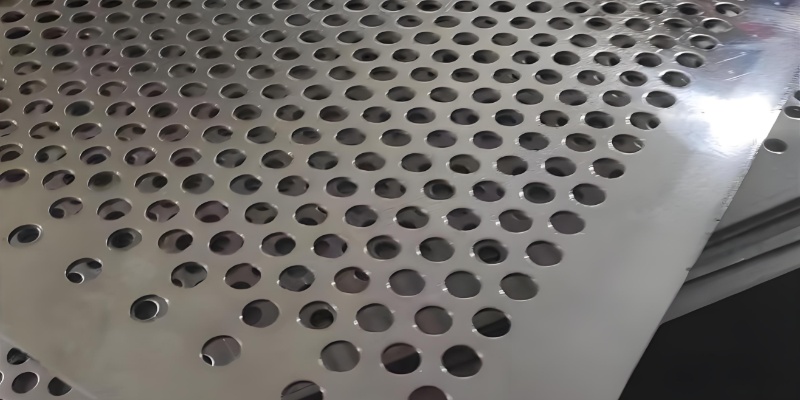

The hole size in perforated metal sheets—typically measured by diameter for round holes or by other dimensional parameters for various shapes—directly influences performance and usability. Choosing the right hole size requires careful consideration of the intended use:

1. Filtration and Screening

For filtration and material separation, precision in hole size is crucial. Smaller holes are ideal for filtering fine particles (e.g., in food processing), while larger holes are suitable for coarse screening (e.g., in mining operations). The correct aperture ensures efficient throughput and accurate material separation.

2. Ventilation and Noise Reduction

In ventilation and acoustic applications, hole size must strike a balance between airflow and sound attenuation. Larger holes promote better air movement but may compromise soundproofing, while smaller holes are more effective in reducing noise. For instance, medium-sized perforations are commonly used in subway ventilation panels to ensure both air circulation and noise control.

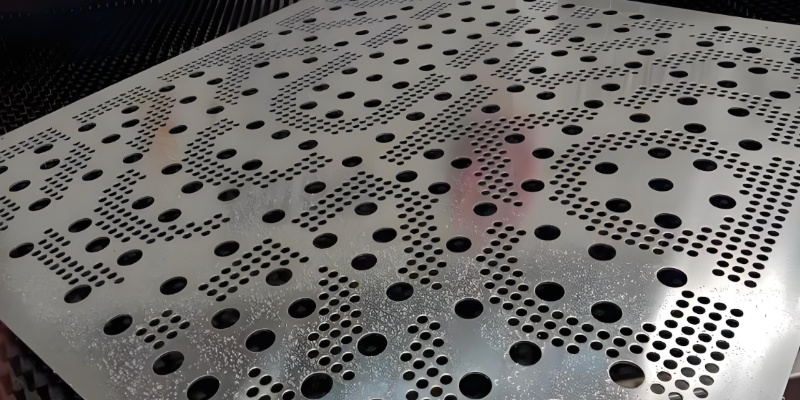

3. Decoration and Visual Effects

In architectural and interior design, hole size plays a major role in the overall visual impact. Small perforations provide refined and elegant detail, suitable for luxury lobbies or art installations. In contrast, large holes present a bold, industrial style, suitable for factories and modern minimalism themes.

4. Load-Bearing and Structural Strength

When perforated sheets need to bear loads or resist impact, the hole size must be carefully chosen to avoid weakening the material. Engineering applications such as machine housings require an optimal balance between ventilation and protective strength. Selecting the correct hole size helps ensure both function and safety.

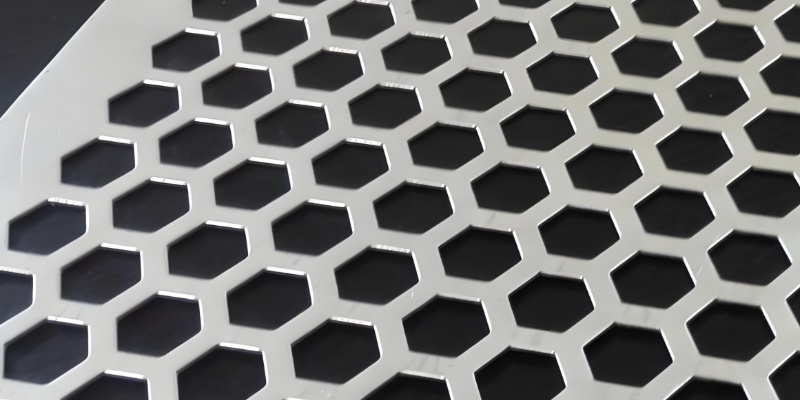

3. Combining Hole Types and Sizes for Custom Designs

Beyond choosing hole shapes and sizes individually, combining different hole types and hole sizes in one sheet allows for multifunctional and visually dynamic designs. For example, integrating round and rectangular holes can provide simultaneous airflow and filtration capabilities. Pairing hexagonal and diamond holes can boost both structural performance and artistic appeal. This design flexibility expands the potential applications of perforated metal sheets across industries.

4. Conclusion

The selection of hole types and hole sizes in perforated metal sheets is a multidimensional decision involving aesthetics, mechanical performance, airflow, and cost-efficiency. From classic round holes to creative irregular patterns, each perforation design serves unique purposes across industrial, architectural, and decorative fields. Through thoughtful customization, perforated sheets can deliver outstanding performance and become a vital component in various applications.

For more information on custom perforated metal designs, materials, and production solutions, feel free to contact us. Our team offers professional support to help you choose the most suitable perforation pattern for your project needs.