3. Application Scenarios

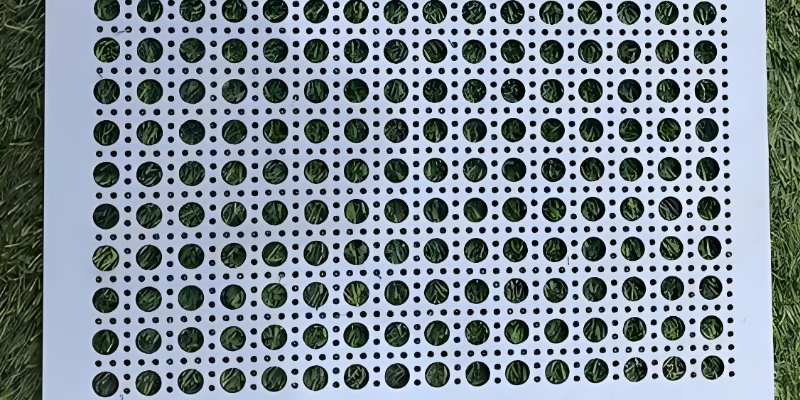

Perforated Metal Sheets

Architectural Decoration: Used for exterior facades, ceiling panels, interior partitions.

Industrial Filtration and Separation: Ideal for sieves, filters, and separators in the food, pharmaceutical, and chemical industries.

Safety and Protection: Applied as protective machine covers, electromagnetic shielding panels, and air safety grilles.

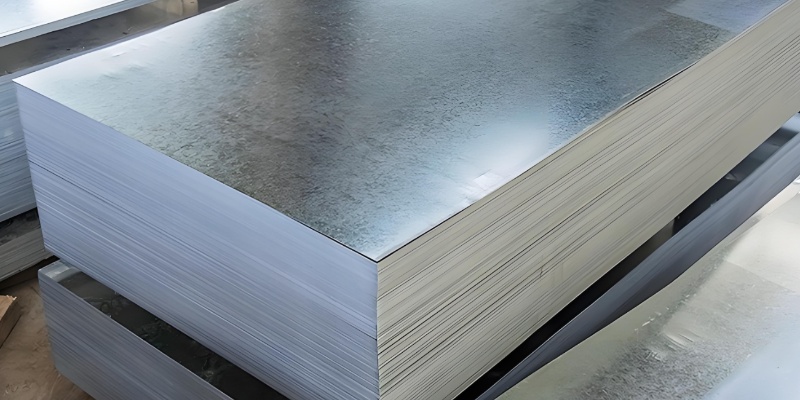

Plain Metal Sheets

Structural Support: Commonly used in foundational frameworks for construction and mechanical engineering.

Surface Cladding: Acts as a protective or decorative layer on walls, floors, or equipment casings.

4. How to Choose the Right Metal Sheet?

Choosing between perforated metal sheets and plain metal sheets depends on the specific needs of your project. If your application calls for enhanced ventilation, acoustic performance, or visual appeal, perforated metal sheets are the better choice. On the other hand, if your primary concern is structural strength and simplicity, plain metal sheets are more suitable.

In addition to form, consider factors such as material type (stainless steel, aluminum, carbon steel), thickness, hole design, and surface treatment to ensure optimal performance in your specific environment.

5. Conclusion

While both perforated and plain metal sheets belong to the same material category, they serve very different roles in practical applications. Perforated metal sheets offer decorative and functional advantages like noise control, airflow, and weight reduction, making them indispensable in modern architecture and industry. Plain metal sheets, known for their simplicity and strength, are ideal for structural use and foundational builds.

Making the right choice based on your project’s functional and aesthetic requirements will lead to better results in durability, performance, and overall design impact.