5. Sheet Dimensions

Standard dimensions vary depending on the material used:

Stainless Steel Sheets: 1000mm × 2000mm, 1220mm × 2440mm, 1500mm × 3000mm

Aluminum Sheets: Typically 1000mm × 2000mm, 1220mm × 2440mm

Galvanized Steel Sheets: 1000mm × 2000mm, 1250mm × 2500mm

Custom dimensions are available upon request to meet specific project needs.

6. Surface Treatment

To improve performance and aesthetics, metal perforated sheets can undergo various surface treatments:

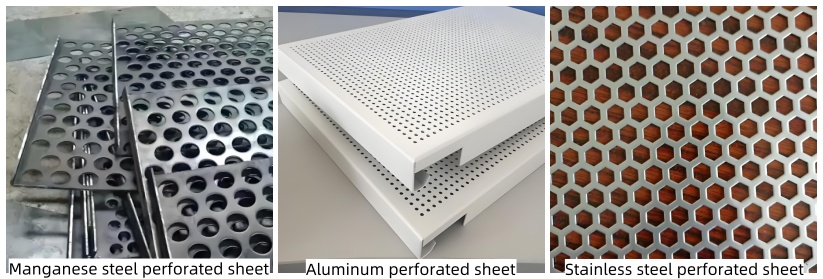

Stainless Steel: Options include 2B finish, brushed, electro-polished, or mirror-polished.

Aluminum: Anodizing, electrophoresis coating, and powder coating available.

Galvanized Steel: Powder coating in a variety of colors.

Cold Rolled Steel: Can be painted or electroplated.

Hot Rolled Steel: Often hot-dip galvanized, with zinc layers up to 80μm thick.

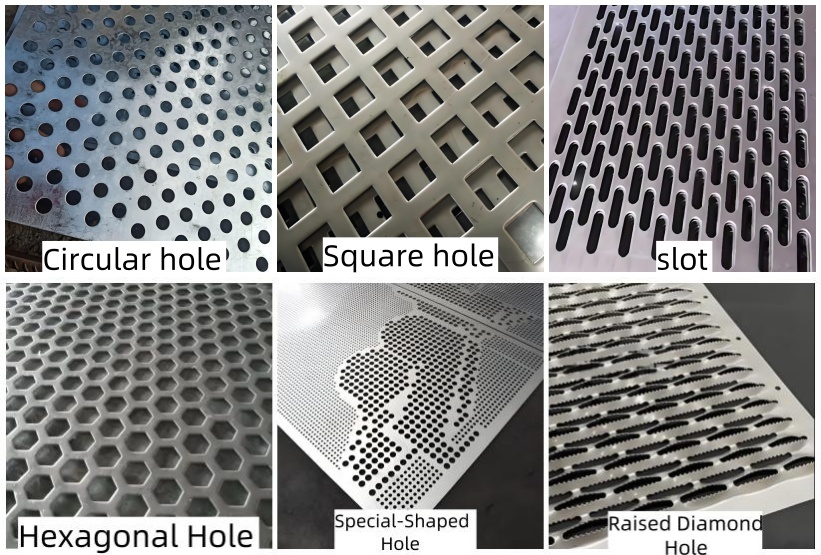

By understanding the full range of metal perforated sheet specifications, you can confidently select the right material, hole type, and finish for your application. For tailored solutions, feel free to contact our expert team for personalized assistance.