The Relationship Between Hole Diameter and Thickness in Perforated Aluminum Sheet Processing

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-19 14:35:24 Browse:

In the production of perforated aluminum sheet, the relationship between hole diameter (or side length) and sheet thickness is a key factor that cannot be overlooked. Generally, to ensure stability during the punching process and maintain a high-quality output, the hole size should not be smaller than the actual thickness of the aluminum sheet.

If the hole is too small, the punching pin is likely to get stuck during the operation, resulting in frequent pin breakage. This not only affects production efficiency but also significantly increases the defect rate of finished products.

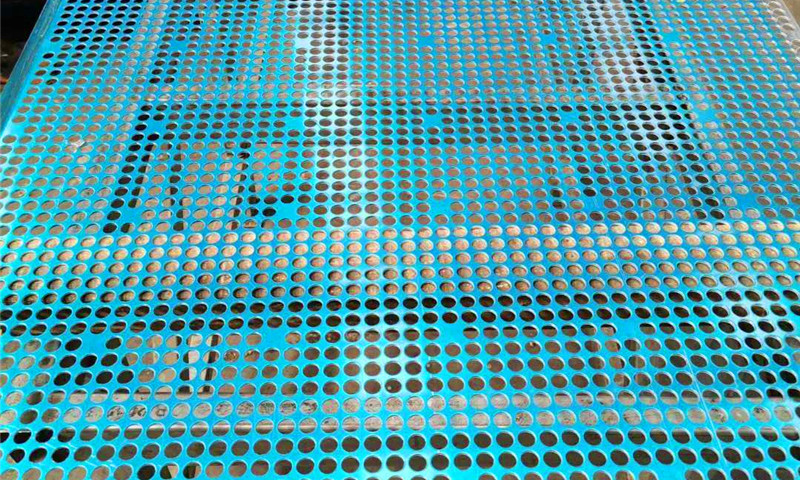

Perforated aluminum sheet

Moreover, the spacing between holes (i.e., the center-to-center distance minus the hole diameter) must also match the sheet thickness. When the spacing is too narrow, the perforated aluminum sheet may lose its overall rigidity after punching. During the flattening process, the sheet is prone to warping or unevenness, which negatively impacts flatness and aesthetics. These deformations are especially difficult to correct in large-area installations or secondary processing.

To ensure stable production and high-quality forming of perforated aluminum sheets, it is recommended to confirm the following two points with your manufacturer during the design or ordering phase:

Matching Hole Diameter and Sheet Thickness

Hole diameter ≥ Sheet thickness: Ensures smooth punching and high pass rates.

Leave sufficient space between holes and the sheet edges.

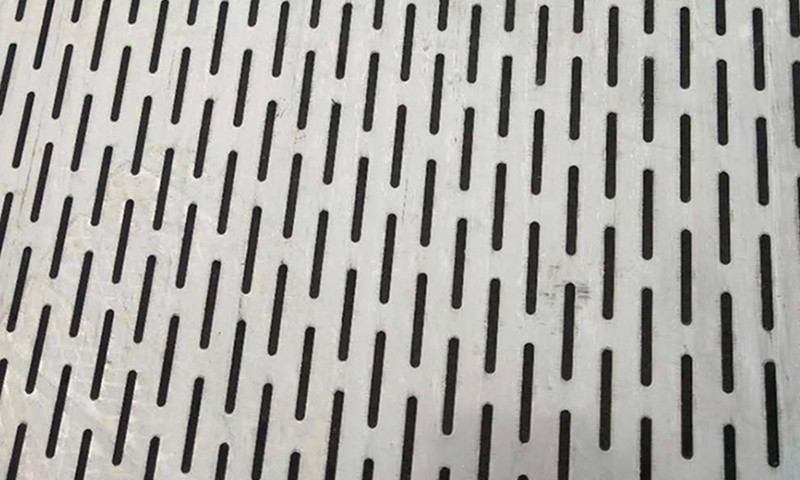

Perforated aluminum sheet

Control of Hole Spacing

Hole spacing ≥ Sheet thickness: Prevents deformation due to concentrated metal stress after punching.

For denser perforation requirements, consider using thicker sheets or higher-strength aluminum alloys.

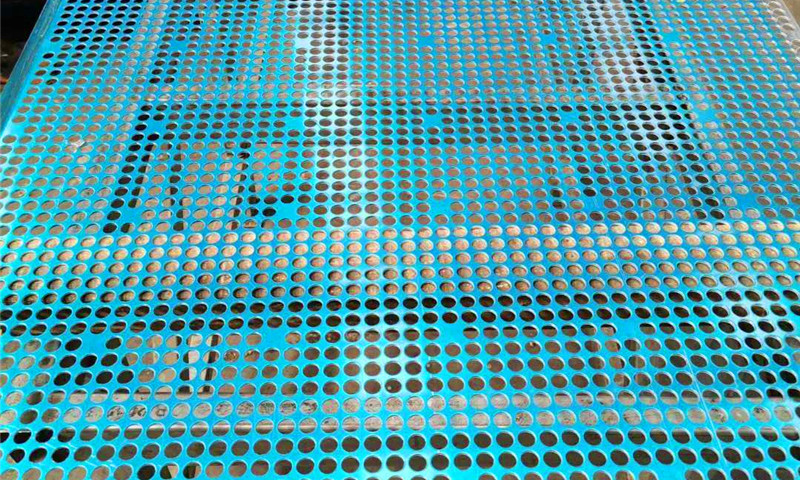

Perforated aluminum sheet

By carefully selecting the right combination of hole diameter and sheet thickness, manufacturers can ensure smooth punching, reduce equipment wear, and improve the flatness and durability of the perforated aluminum sheet. This ultimately leads to better economic performance and visual appeal in the final application.