High‑Quality Perforated Aluminum Sheet: Selection Guide and Customization Tips

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-19 14:45:35 Browse:

1. Introduction

A perforated aluminum sheet is produced by taking premium aluminum plate and using CNC punch‑press equipment with bespoke tooling to create a regular pattern of holes. Hole diameters can be customized from 1 mm up to 100 mm, making the perforated aluminum sheet suitable for sound absorption, ventilation, protection, and decorative applications.

2. Hole‑Diameter Selection Principles

Choosing the right hole diameter ensures that the perforated aluminum sheet meets both functional requirements and aesthetic expectations, while remaining cost‑effective. Below are recommended diameter ranges for three typical use cases.

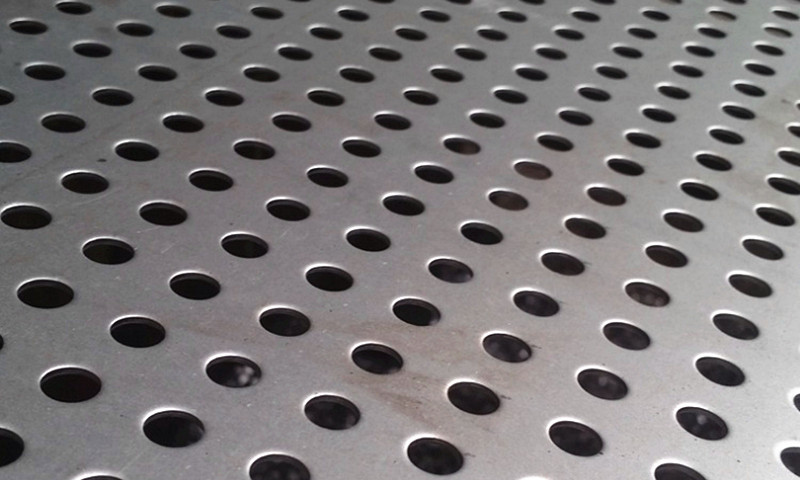

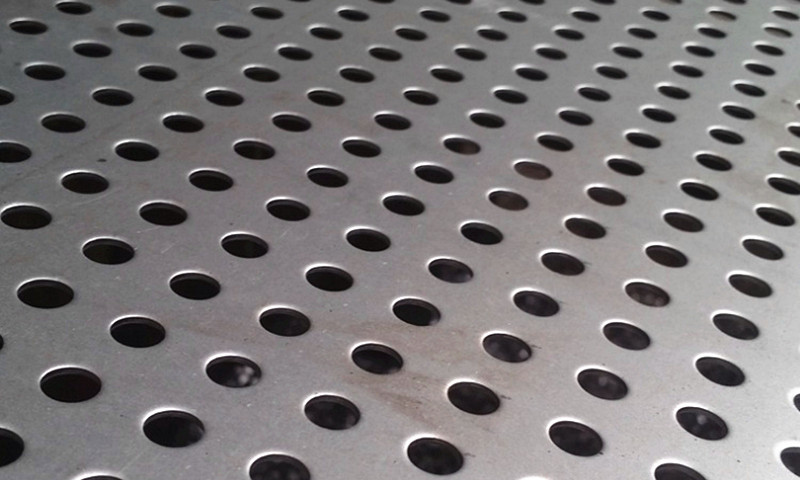

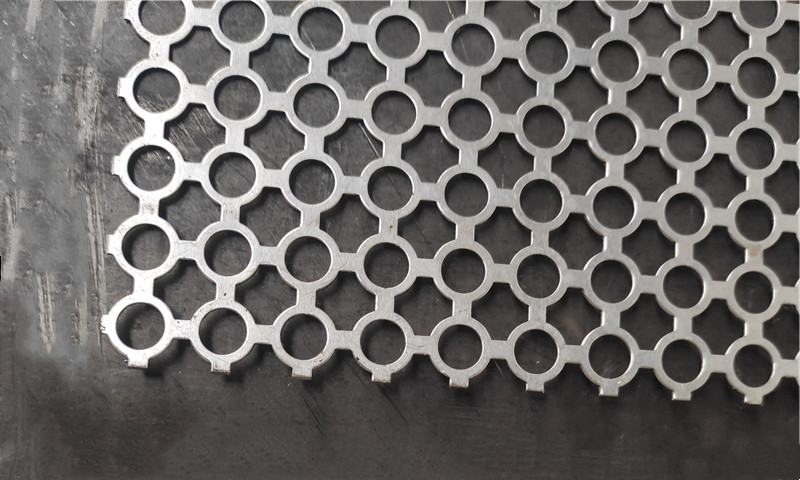

Perforated aluminum sheet

2.1 Sound‑Absorbing & Decorative Panels

Applications: Wall‑mounted sound‑absorption panels, decorative ceilings, and tool boards.

Recommended Diameters: 1 mm, 1.5 mm, 2 mm, 2.5 mm, 3 mm.

Benefits: Small holes effectively trap and dissipate sound energy, while providing a fine visual texture that integrates seamlessly with various surface finishes.

2.2 Mechanical Protective Barriers

Applications: Equipment guards, safety fences, and machine enclosures.

Recommended Diameters: 5 mm to 15 mm.

Benefits: Medium‑sized holes allow sufficient airflow and heat dissipation, while preventing the ingress of larger debris—striking a balance between safety and practicality.

Perforated aluminum sheet

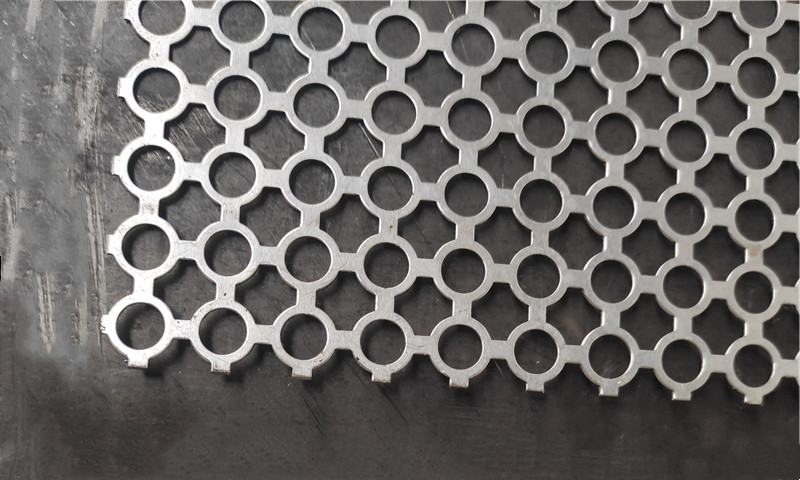

2.3 Exterior Decorative Panels

Applications: Building façades, curtain walls, sunshade louvers, and decorative screens.

Recommended Diameters: 20 mm or larger.

Benefits: Larger holes create dramatic light‑and‑shadow effects at a distance, enhance façade ventilation, and deliver a striking architectural appearance.

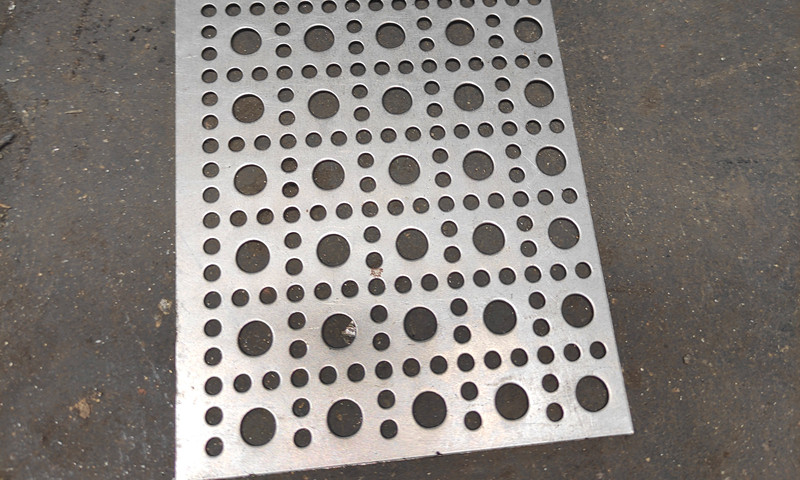

Perforated aluminum sheet

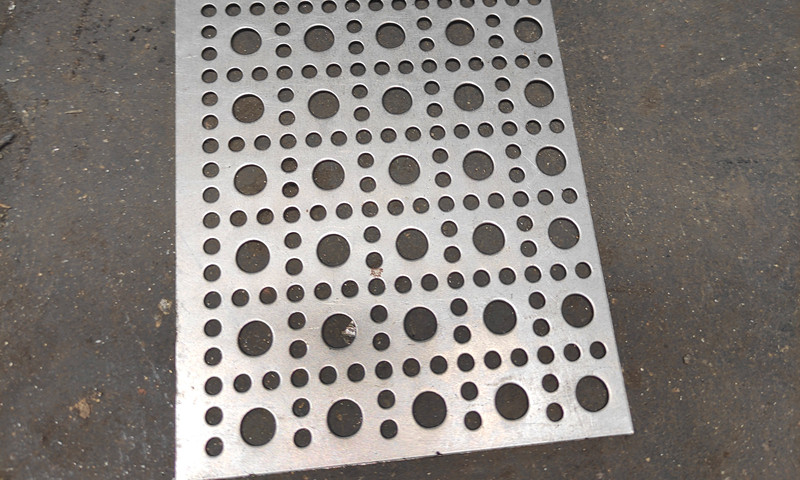

3. Customization Suggestions

Open‑Area Ratio: Larger hole diameters increase the open‑area ratio, directly influencing ventilation, daylight penetration, and visibility. Adjust according to project requirements.

Material Thickness: As hole diameters grow, increase sheet thickness to maintain structural integrity and flatness.

Surface Treatments: Options include powder coating, anodizing, and fluorocarbon finishing, which improve weather resistance and offer a wide palette of colors.

4. Summary

Sound‑absorbing panels: 1 – 3 mm hole diameter

Protective barriers: 5 – 15 mm hole diameter

Exterior decoration: ≥ 20 mm hole diameter

By combining the right hole diameter with open‑area ratio, material thickness, and surface treatment, you can fully customize your perforated aluminum sheet to achieve optimal performance and visual impact.