Professional Walkway Grip Strut Safety Grating Solutions | Global Custom Services

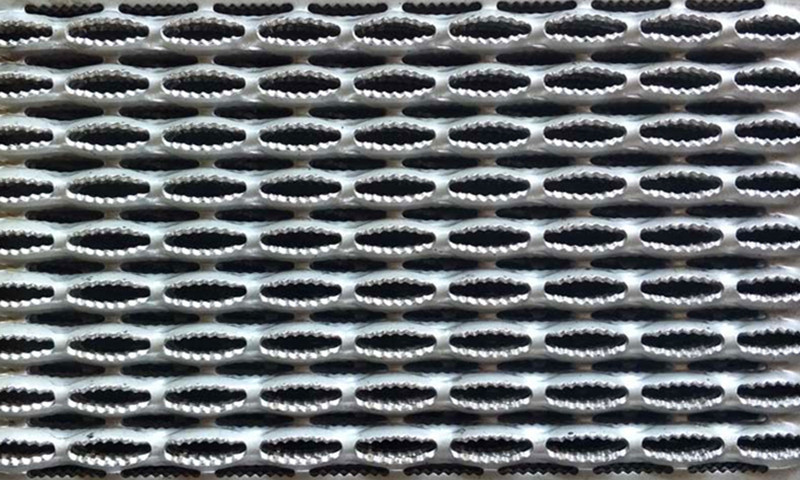

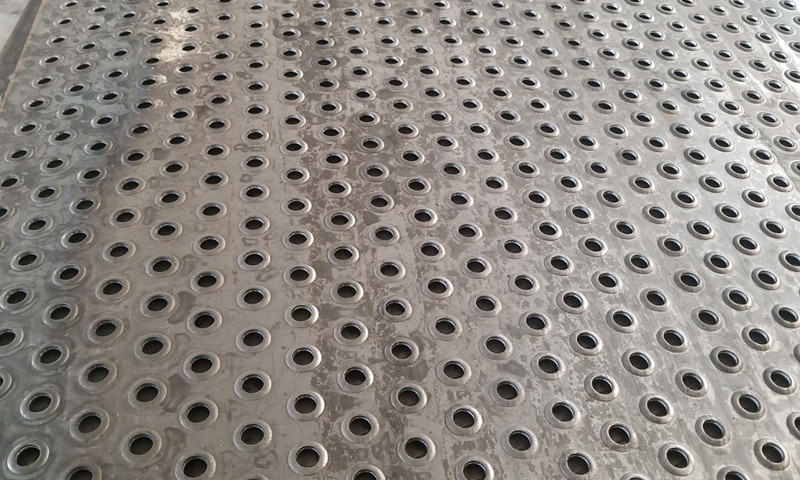

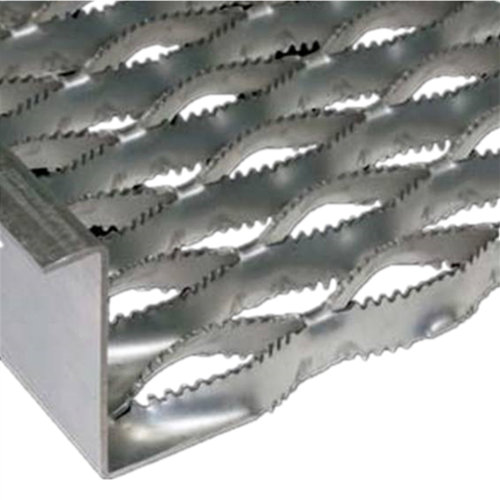

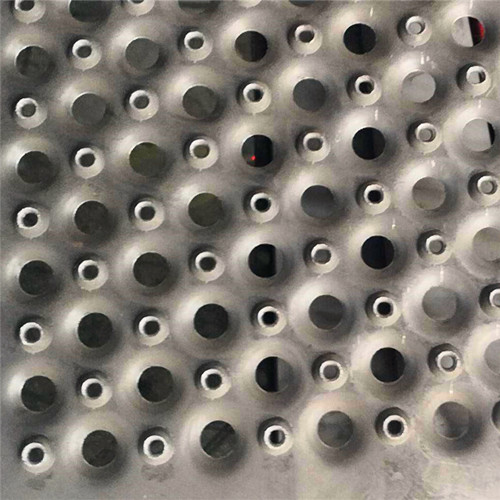

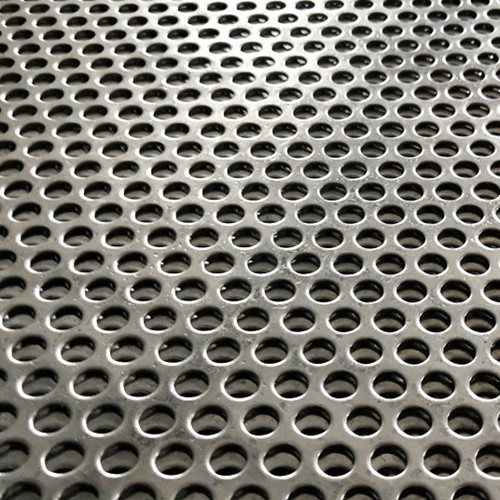

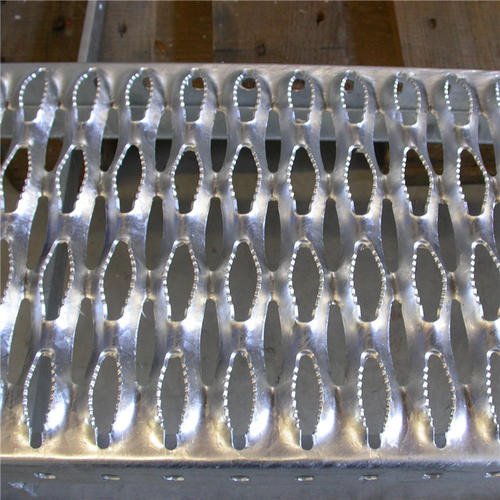

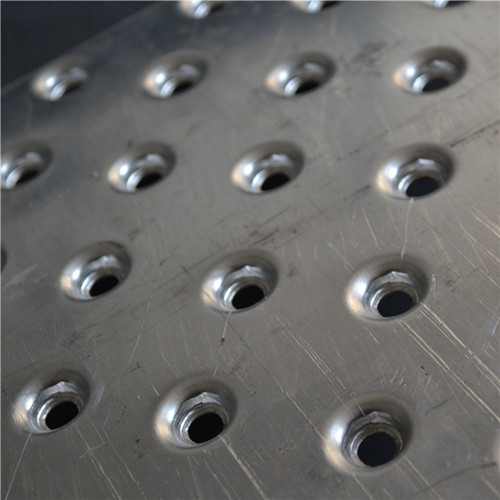

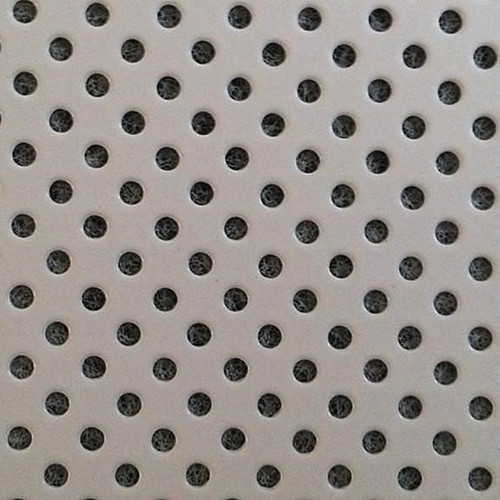

Walkway Grip Strut Safety Grating is a specialized metal safety flooring system designed for industrial environments. Manufactured using CNC punching technology, it features unique anti-slip textures formed directly into the steel surface through a single-piece molding process. This innovative approach allows for customization based on varying load requirements, such as adjusting material thickness and hole patterns, to significantly enhance workplace safety. Ideal for high-risk areas, it prevents slips and falls while ensuring long-term reliability under demanding conditions.

Material Specifications and Technical Details

Our Walkway Grip Strut Safety Grating offers versatile options to suit different industrial needs. It’s crafted from robust materials like carbon steel, galvanized steel, 304/316 stainless steel, and aluminum alloys, all chosen for industrial-grade resilience. Standard thickness ranges from 2.0-3.5mm, with precision adjustments available in 0.5mm increments to meet specific weight demands. Common dimensions include 1000×2000mm and 1200×2400mm, but we support custom cutting for non-standard sizes, ensuring a perfect fit for any project.

For surface treatments, we provide advanced finishes tailored to harsh environments. Hot-dip galvanizing is ideal for salt-rich settings like ports and ship decks, offering superior corrosion resistance. Electrostatic powder coating comes in a full RAL color spectrum, maintaining vibrant hues for over a decade with minimal fading. Additionally, anodizing is recommended for food-grade aluminum applications, ensuring compliance with hygiene standards while enhancing durability. These treatments extend the product lifespan and reduce maintenance costs.

Unmatched Advantages for Engineering and Maintenance

Our Walkway Grip Strut Safety Grating boasts exceptional engineering benefits, starting with its efficient drainage. The herringbone hole design enables rapid water runoff at 300L per minute per square meter, preventing pooling and ice buildup. Load performance is top-tier, with a 3mm-thick steel variant supporting dynamic loads of up to 2.5 tons per square meter. Temperature tolerance spans from -40°C to 120°C, ensuring stable physical properties in diverse climates.

Installation and upkeep are simplified for cost-effectiveness. A no-weld modular clip system allows for quick assembly without specialized tools, reducing labor time. Cleaning is hassle-free with high-pressure water jet compatibility, eliminating dirt traps for hygienic environments. Damaged sections can be replaced individually, minimizing downtime and expenses. These features make it a smart investment for businesses prioritizing safety and efficiency.

Custom Service Workflow for Global Clients

Our tailored approach begins with a detailed needs assessment phase. We start by evaluating environmental factors like temperature, humidity, and chemical exposure through on-site data collection. Next, our engineering team performs precise load simulations to calculate weight-bearing requirements. Finally, clients review and approve DXF or CAD format drawings before production, ensuring accuracy and satisfaction.

Production is backed by rigorous quality controls. Raw materials include traceable steel batches with full certification documents, while in-process inspections use coordinate measuring machines to monitor hole spacing accuracy. Packaging features dual protection with wooden pallets and waterproof films for secure shipping. Globally, our logistics network supports seamless delivery with region-specific solutions. Examples include CE compliance documents for the EU, ASTM test reports for North America, specialized coatings for Southeast Asia’s humid climates, and heat-resistant formulas for the Middle East’s high-temperature zones.

Technical Support and Contact Information

For inquiries, email us at 342096438@qq.com —support is available in English, Chinese, and Russian. We respond within 12 business hours with a preliminary solution. Downloadable resources like PDFs and technical datasheets are provided for quick reference. Reach out today to enhance your facility’s safety with our reliable Walkway Grip Strut Safety Grating.

2025-03-04

2025-05-21

2025-05-19

2025-01-10

2025-06-14

2025-06-07

2025-05-13

2025-05-19

2025-06-14

2025-04-11

Grip Strut Safety Grating

Perforated Grip Strut Safety Grating

Carbon Steel Grip Strut Safety Grating

Walkway Grip Strut Safety Grating

Stainless Steel Grip Strut Safety Grating

Stainless Steel Sieve Sheet

Aluminum Anti-skid Plate

Stair Grip Strut Safety Grating

Galvanized Safety Grating

Carbon Steel Perforated Sheet

Grain Sorting Screen Plate

Metal Safety Grating

Convex Hole Anti-skid Plate

Galvanized Screening Plate

Circular Hole Sieve Sheet