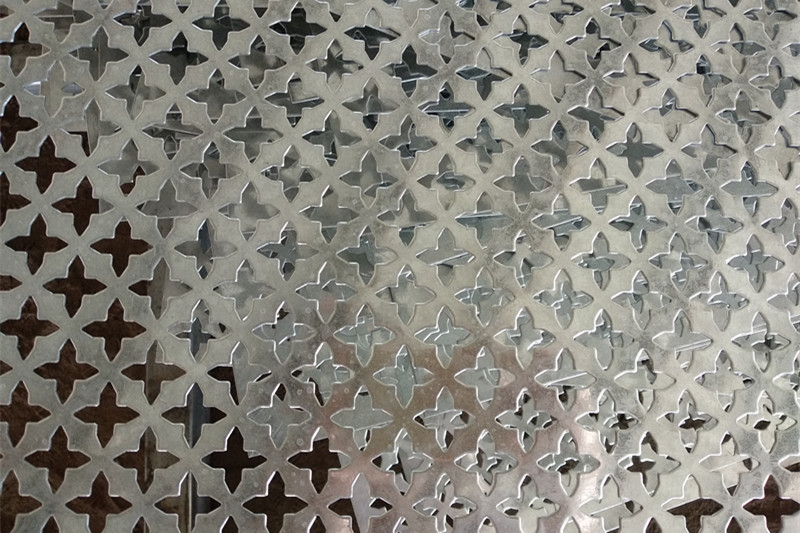

Cross Hole Perforated Sheet Introduction

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-04-23 07:55:03 Browse:

In fields such as architectural decoration, mechanical protection, and ventilation filtration, the cross hole perforated sheet stands out as a star product among perforated metal sheets thanks to its unique hole pattern and superior performance. This article will comprehensively explore the advantages and value of cross hole perforated sheets from five key aspects: product overview, technical parameters, manufacturing process, surface treatment, and typical applications, helping you to understand and select the right product with precision.

1. Product Overview

The cross hole perforated sheet is a perforated metal sheet made from cold-rolled steel, hot-rolled steel, galvanized steel, or stainless steel sheets, processed using punch presses or laser cutting. Its holes are arranged in a cross pattern, offering various combinations of aperture and spacing as required. It not only delivers a decorative effect but also fulfills functions such as ventilation, filtration, and protection.

2. Technical Parameters

Sheet Thickness: 0.2–10 mm, customizable according to project requirements;

Common Materials:

Galvanized Steel (excellent corrosion resistance, cost-effective)

Cold-Rolled Steel (high flatness, easy to paint)

Stainless Steel (corrosion-resistant, high-temperature resistant, ideal for outdoor and special environments)

Hole Specifications:

Primary: Cross holes (crisscross pattern)

Optional: Slotted holes, square holes, round holes, oval holes, pentagon holes, fisheye holes, combined holes, flower-shaped holes, etc.

Hole Diameter Range: φ3 mm–φ50 mm;

Hole Pitch (center distance): Available in 3 mm, 4 mm, 5 mm, 6 mm, 8 mm, 10 mm, 20 mm, or customized as specified;

Sheet Dimensions: 1220×2440 mm, 1200×600 mm, 1000×2000 mm, 1000×500 mm, 500×600 mm, etc., customizable based on project drawings.

All these parameters can be flexibly combined to meet various engineering or decorative needs. Choosing the right cross hole perforated sheet not only enhances the project's aesthetic appeal but also meets practical functional requirements.

Cross hole perforated sheet

3. Manufacturing Process

Material Selection

Strictly selected high-quality national standard cold-rolled, hot-rolled, and 304/316 stainless steel sheets, ensuring flatness and impurity-free substrates.

CNC Punching/Laser Cutting

Using German-imported CNC punching or laser cutting equipment, achieving ±0.1 mm processing precision with smooth, burr-free hole edges.

Deburring and Leveling

Post-punching deburring through polishing or vibrating processes, followed by automatic leveling to improve flatness.

Surface Protection

Options include electrophoresis, electrostatic spraying, powder coating, hot-dip galvanizing, fluorocarbon spraying, or electrolytic polishing to enhance weather resistance and aesthetic appeal.

Quality Inspection and Packaging

Rigorous inspection of hole dimensions, flatness, and coating adhesion, followed by waterproof and moisture-proof packaging per customer requirements to ensure safe logistics and transportation.

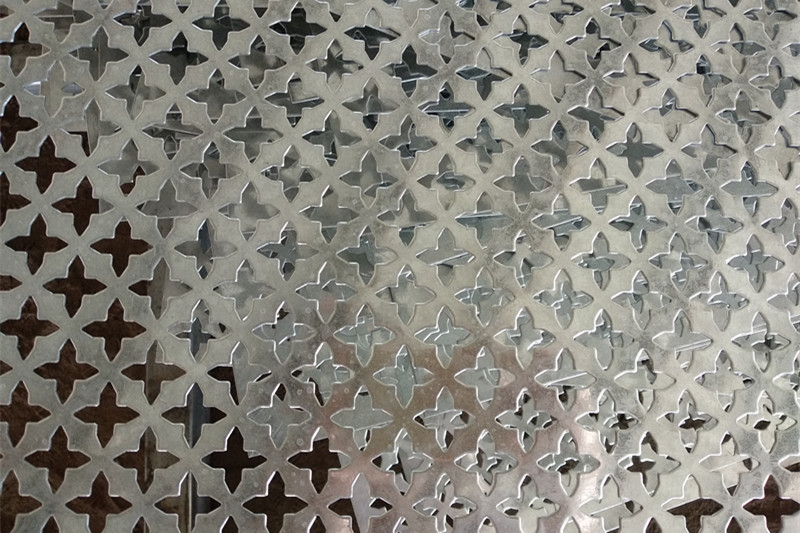

4. Surface Treatment

Electrostatic Powder Coating: Rich colors, strong adhesion, suitable for indoor and outdoor decoration.

Hot-Dip Galvanizing: Outstanding corrosion resistance and long-lasting rust protection, often used for outdoor barriers.

Fluorocarbon Spraying: Tough coating, UV-resistant, acid and alkali-resistant, ideal for premium commercial buildings.

Electrolytic Polishing (Stainless Steel): Excellent mirror finish, easy to clean, perfect for high-end decorations and kitchen & bathroom equipment.

Painting/Powder Spraying: Customizable according to the RAL color chart to meet diverse color needs.

Cross hole perforated sheet

5. Typical Applications

Architectural Facades and Decoration

Shopping centers, office building exteriors, and indoor partition screens utilizing the three-dimensional texture and ventilation features of cross hole perforated sheets to create modern aesthetics.

Road Barriers and Protective Fencing

Highway isolation barriers and urban greenbelt fencing, combining safety, impact resistance, and visual permeability.

Mechanical Equipment and Ventilation Filtration

Fan guards, filter shells, and sound barriers, offering precise hole patterns and high flatness to ensure smooth airflow and prevent foreign object intrusion.

Lighting and Custom Home Décor

Chandelier shells and decorative furniture panels, utilizing the light and shadow effects of cross hole perforated sheets to add spatial depth.

Acoustic Absorption

Acoustic panels for cinemas and conference rooms, achieving excellent sound absorption through a combination of perforation patterns and backing materials.

6. Why Choose Us?

Professional Customization: One-stop customization of hole types, spacing, sheet material, and dimensions.

Strict Quality Control: Full-process quality monitoring, ensuring flat, burr-free sheets with precise hole patterns.

Competitive Pricing: Years of production experience with a stable supply chain offering high cost-performance.

Fast Delivery: Stock and custom production run simultaneously to meet urgent delivery needs.

Comprehensive Service: Technical selection guidance, sample trials, and after-sales support.

For more information about cross hole perforated sheet specifications, quotations, and samples, feel free to call or consult online. We are ready to provide professional solutions to ensure the successful implementation of your engineering and decoration projects!