Cross Hole Perforated Sheet Styles and Applications

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-04-23 08:07:47 Browse:

A Cross Hole Perforated Sheet is a popular type of perforated metal sheet known for its distinctive cross-shaped holes and evenly spaced layout. It features advantages such as cost efficiency, high flatness, burr-free surfaces, and excellent load-bearing performance. Cross hole perforated sheets are widely used in architectural decoration, filtration and screening, protective barriers, and acoustic sound absorption applications.

Common Styles of Cross Hole Perforated Sheet

Based on the perforation process and the sharpness of the hole edges, Cross Hole Perforated Sheets are mainly categorized into two types:

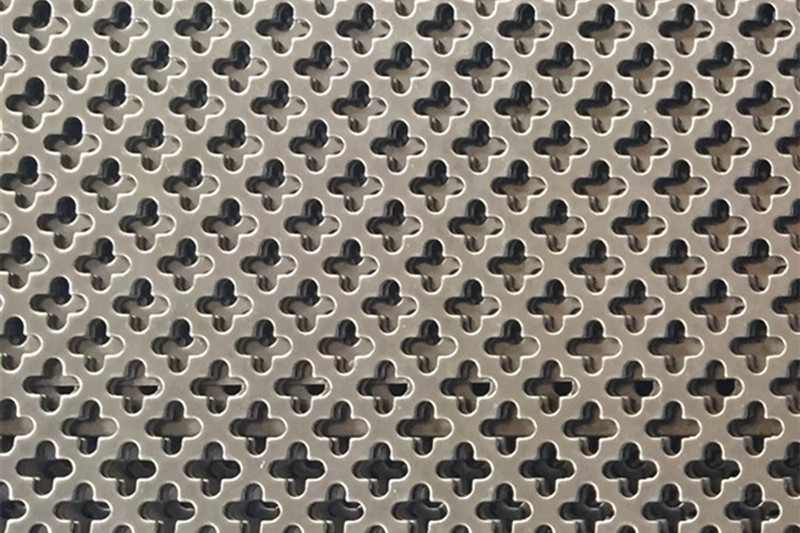

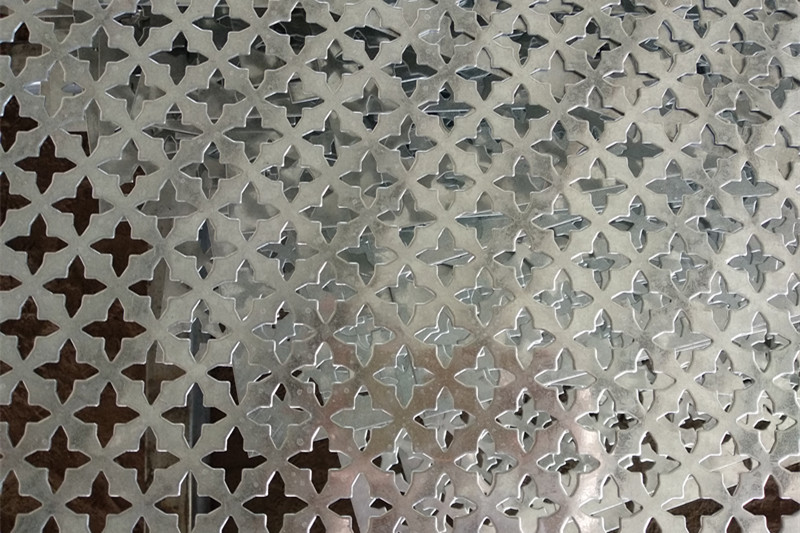

Smooth Cross Holes

Rounded, smooth hole edges without sharp corners;

Ideal for applications requiring aesthetics and safety, such as decorative panels, railings, and protective covers;

Commonly used in premium curtain walls, indoor partitions, and artistic decorative projects.

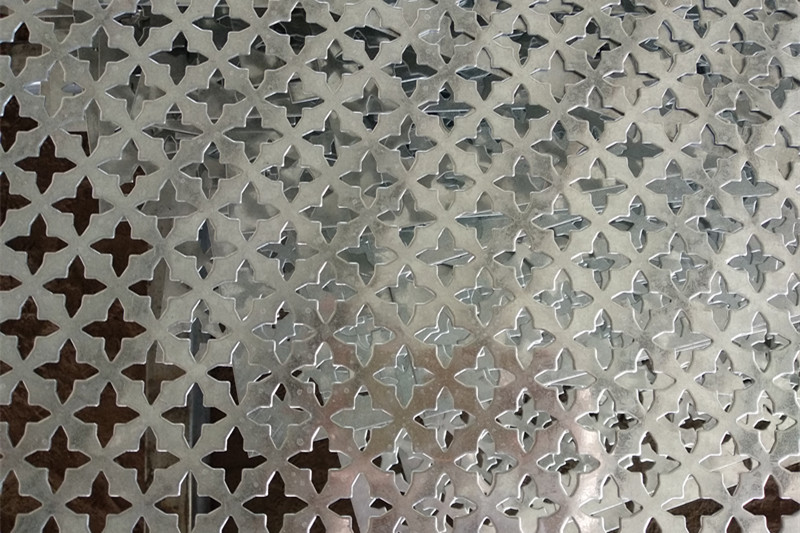

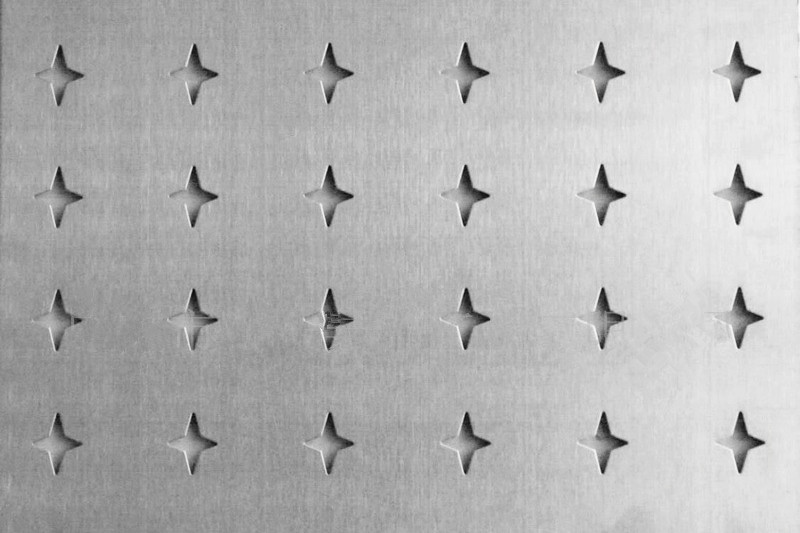

Sharp Cross Holes

Sharp-edged, blade-like hole openings;

Suitable for screening, filtration, and cutting applications with high cutting efficiency;

Often applied in industrial filters, screening meshes, and sandblasting filters.

Tip: When choosing a cross hole perforated sheet style, it is recommended to balance aesthetic needs with functional requirements.

Overview of Specifications

Despite the variety of styles, the specifications of cross hole perforated sheets are relatively standardized, typically including:

Sheet Thickness: 0.2–10 mm, customizable based on load-bearing and aesthetic needs;

Hole Size (Width/Height): Common range from 3–50 mm;

Pitch: Customizable according to client requirements, standard options include 5, 6, 8, 10, 20 mm;

Sheet Dimensions: 1220×2440 mm, 1200×600 mm, 1000×2000 mm, 1000×500 mm, 500×600 mm, also customizable by drawing;

Layout Angle: Mostly arranged at a 60° diagonal angle, adjustable upon design request.

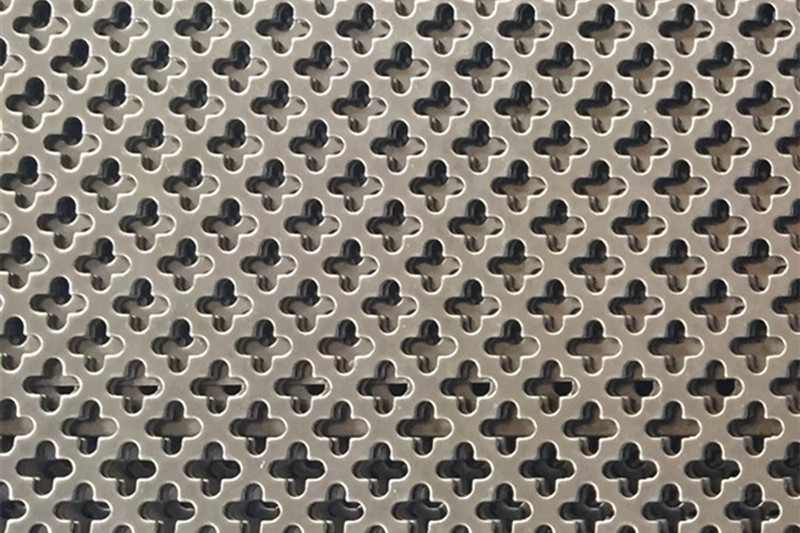

Cross hole perforated sheet

Materials and Processing Techniques

The main materials for Cross Hole Perforated Sheets include:

Aluminum Sheet (lightweight, high-strength, excellent weather resistance).

Common processing methods:

CNC Punching: High efficiency and precision, suitable for large-scale production;

Laser Cutting: Narrow kerf and minimal heat effect, ideal for complex patterns and small-batch production;

Mold Stamping: Low-cost mass production with excellent consistency in hole shapes.

Surface Treatment and Anti-Corrosion

To enhance durability and decorative effects, Cross Hole Perforated Sheets are commonly treated with:

Powder Coating: Rich colors and strong anti-corrosion performance;

Electrostatic Spraying: Strong adhesion with an even coating;

Fluorocarbon Coating: Superior weather resistance, suitable for exterior curtain walls;

Brushed/ Mirror Polishing (for stainless steel): High-end texture, easy to clean;

Electroplating/Electrophoresis: Achieves various metallic color effects.

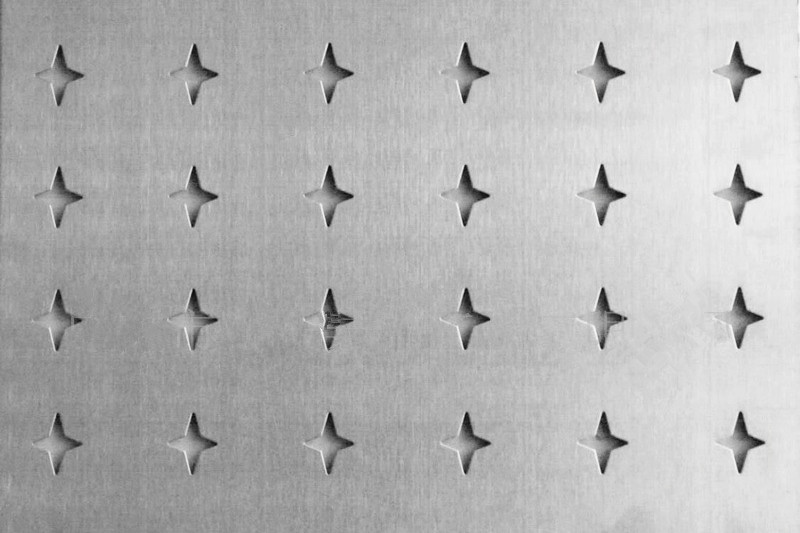

Cross hole perforated sheet

Advantages and Applications of Cross Hole Perforated Sheets

Decorative Aesthetics: Neat cross-hole arrangement and a strong sense of space, widely used in curtain walls, ceiling decorations, and partitions.

Ventilation and Light Transmission: High porosity meets ventilation, lighting, and privacy requirements.

Lightweight Structure: Thin and lightweight metal sheets reduce building loads.

Safety Protection: Stable hole structure with burr-free edges, ideal for machine guards and safety railings.

Multi-Functional Screening: Sharp cross holes are perfect for filtration, screening devices, and high-efficiency cutting.

Typical application scenarios include:

Commercial building curtain walls, indoor partitions

Industrial filtration and screening machinery

Acoustic sound-absorbing panels and protective covers

Cross hole perforated sheet

Furniture decoration and lighting panels

How to Choose the Right Cross Hole Perforated Sheet?

Clarify Usage: Choose smooth cross holes for decorative purposes; select sharp cross holes for screening and filtration needs.

Select Materials: For indoor use, opt for powder-coated carbon steel or brushed stainless steel; for outdoor use, fluorocarbon-coated aluminum or stainless steel with excellent weather resistance is recommended.

Customize Specifications: Determine hole size, pitch, sheet thickness, and layout angle based on load-bearing, ventilation, and aesthetic design needs.

Surface Treatment: Choose anti-corrosion coatings or polishing techniques based on environmental conditions and visual appeal.

Find a Professional Manufacturer: Partner with an experienced Cross Hole Perforated Sheet manufacturer to get one-stop technical support, fast prototyping, and bulk production services.

With a wide variety of styles and flexible customization capabilities, Cross Hole Perforated Sheets have become the versatile choice for both architectural decoration and industrial applications. Whether pursuing visual appeal or fulfilling functional needs, you can find precise solutions with a professional manufacturer. Contact us today to get the highest quality Cross Hole Perforated Sheets and customized services!

Cross hole perforated sheet