Metal Mesh Plate Introduction – Detailed Overview of Material, Specification, Applications & Classification

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-11 18:38:22 Browse:

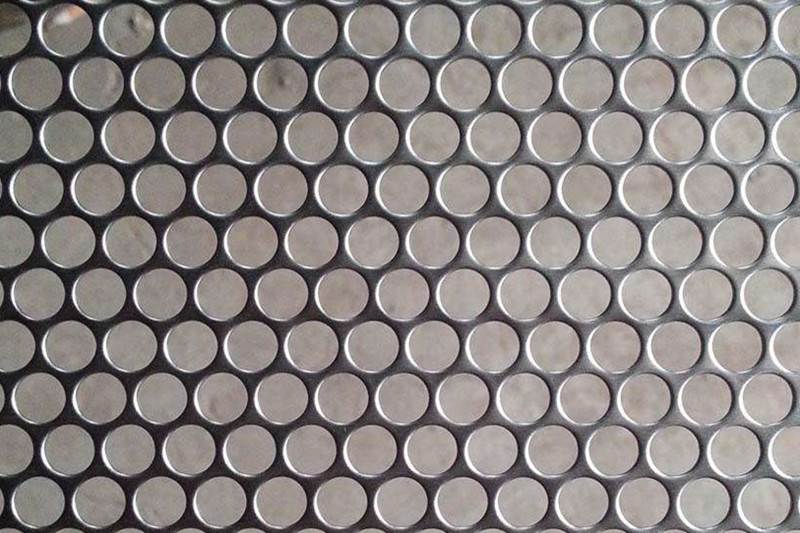

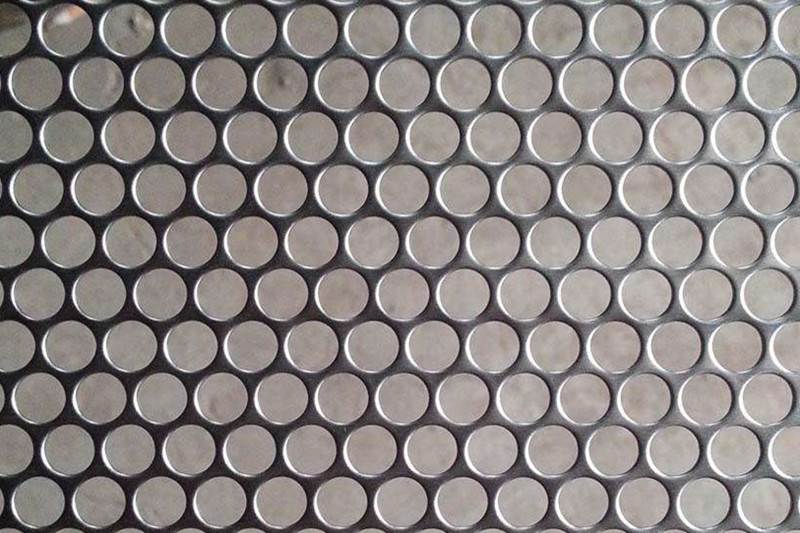

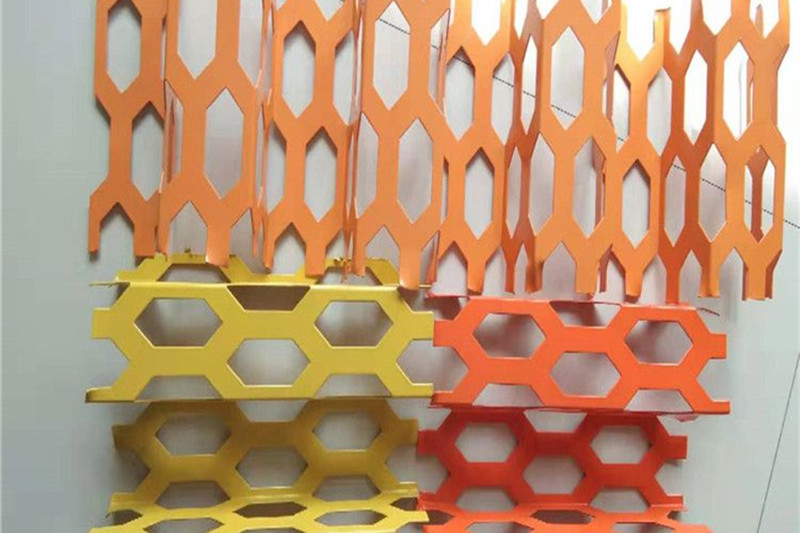

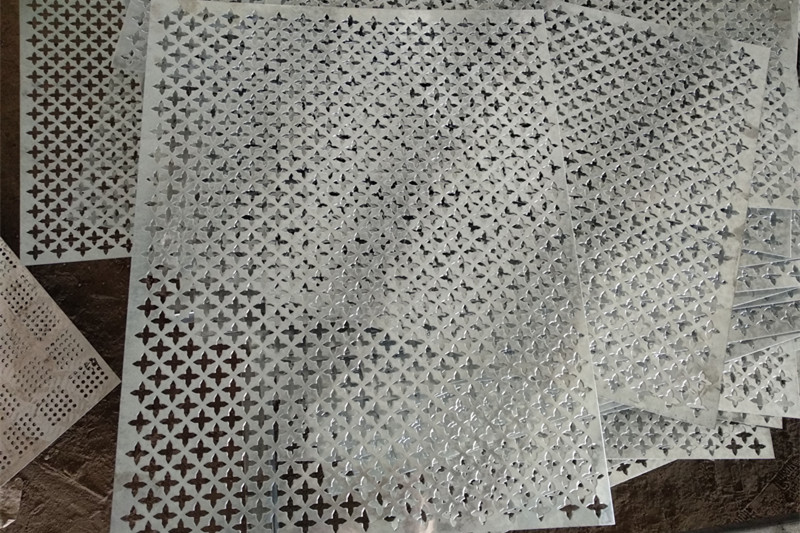

Metal mesh plate, also known as perforated metal sheet, is a functional and aesthetic metal sheet processed by CNC punching equipment. Holes of various shapes and sizes are punched into different types of metal plates following a specific pattern. The finished product features a smooth surface, high durability, excellent corrosion resistance, and superior wear resistance, making it ideal for a wide range of industrial and decorative applications.

I. What Is a Metal Mesh Plate?

A metal mesh plate is produced by punching holes into a variety of metal sheets, such as cold-rolled steel, hot-rolled steel, stainless steel, aluminum, galvanized sheet, and more. These holes can be arranged in various patterns depending on the functional and visual requirements. With outstanding load-bearing capacity and good air permeability, metal mesh plates are widely used in architectural decoration, equipment protection, filtering systems, and more.

Metal mesh plate

II. Metal Mesh Plate Specifications

We provide customized production based on your specifications. Detailed parameters include:

Available Materials: Cold-rolled sheet, hot-rolled sheet, galvanized sheet, stainless steel (304, 316, etc.), aluminum plate, copper plate, nickel plate, manganese steel plate, and more;

Thickness Range: From ultra-thin 0.1mm up to heavy-duty 20mm metal plates;

Hole Diameter Range: Holes can range from 1.0mm to 200mm, with fully customizable spacing;

Standard Sizes:

1000mm × 2000mm

1220mm × 2440mm

1250mm × 2500mm

Coil Sizes: 1m × 20m, 1.2m × 20m, 1.5m × 20m

Non-standard dimensions available upon request;

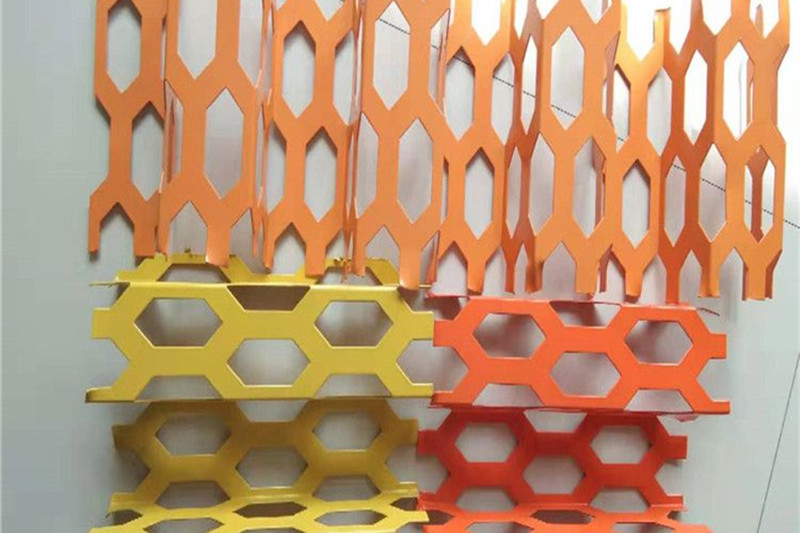

Surface Treatments: Powder coating, painting, electroplating, polishing, anodizing, anti-rust oil, etc.;

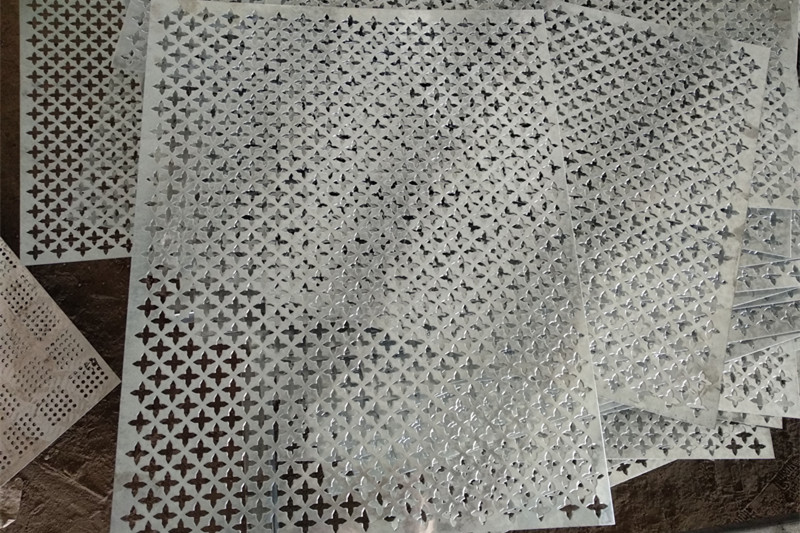

Hole Types: Round, square, long slot, oval, fish-eye, hexagonal, pentagonal, floral, irregular, crocodile mouth-shaped, and more – available in both decorative and industrial styles.

Metal mesh plate

III. Applications of Metal Mesh Plate

Thanks to its structural diversity and mechanical performance, metal mesh plate is widely adopted across various industries:

Architectural Design: Facades, ceilings, room dividers, stair treads, and wall cladding;

Equipment Protection: Safety covers and shields for machinery;

Ventilation and Cooling: Used in warehouses, cold storage, and mechanical rooms for air circulation;

Acoustic Engineering: Speaker grilles and sound-absorbing wall panels;

Screening & Filtration: Separation and filtration in mining, chemical, food processing, and water treatment;

Household & Kitchen: Storage racks, ventilation panels, oil filters;

Security & Traffic: Road barriers, factory fences, anti-slip walkways, drainage covers;

Craft & Furniture Design: Artistic decor, lighting fixtures, and modern furniture manufacturing.

Metal mesh plate

IV. Classifications of Metal Mesh Plates

To cater to diverse requirements, metal mesh plates can be classified as follows:

By Material:

Iron metal mesh plate

Galvanized metal mesh plate

Stainless steel metal mesh plate

Aluminum metal mesh plate

Copper metal mesh plate

Plastic perforated sheet (non-metal)

By Hole Type:

Round hole, square hole, slot hole, hexagonal, fish-eye, pentagon, oval, decorative floral patterns, irregular hole shapes

By Thickness:

Thin plate (0.1–1mm)

Medium plate (1–5mm)

Thick plate (5–12mm)

Extra-thick plate (12mm and above)

By Processing Method:

Laser perforated sheet

CNC punched sheet

Micro-perforated sheet

Anti-slip raised metal mesh

By Application:

Decorative perforated plate

Safety tread plate

Drainage perforated panel

Filter screen

Sound-absorbing perforated metal plate

Metal mesh plate

V. Why Choose Us as Your Metal Mesh Plate Manufacturer?

We are equipped with advanced CNC punching lines, an experienced engineering team, and years of industry expertise. We offer complete metal perforation solutions from consultation to delivery, ensuring both quality and speed.

Free sample support;

Custom design based on your drawings;

Wide range of materials and hole patterns;

Competitive prices, fast delivery;

100% quality inspection with burr-free, defect-free output;

Looking for a trusted metal mesh plate manufacturer? Contact us today for a quote or sample. We provide reliable quality, customizable solutions, and professional service for your projects.