Differences Between Perforated Metal Sheets of Various Materials

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-07 14:35:35 Browse:

Perforated metal sheets are integral to modern industrial and architectural applications due to their versatility, aesthetic appeal, and functional benefits. The choice of material significantly influences the performance and suitability of these sheets for specific environments. Below is a detailed comparison of commonly used materials in perforated metal sheets:

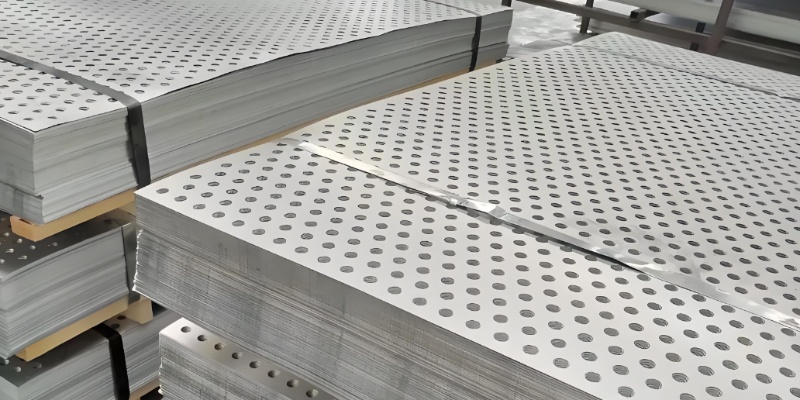

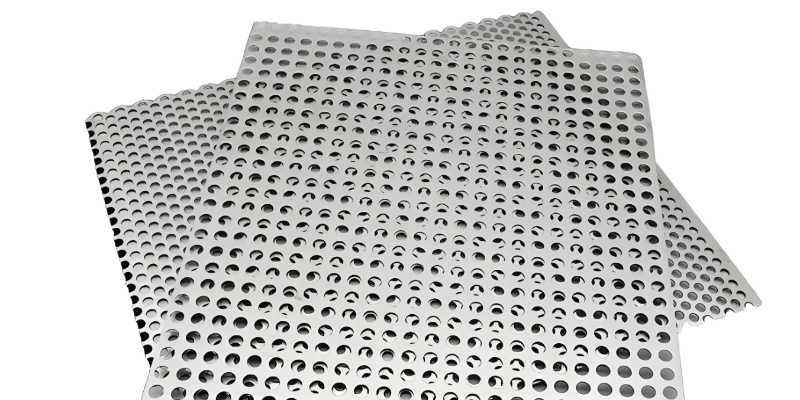

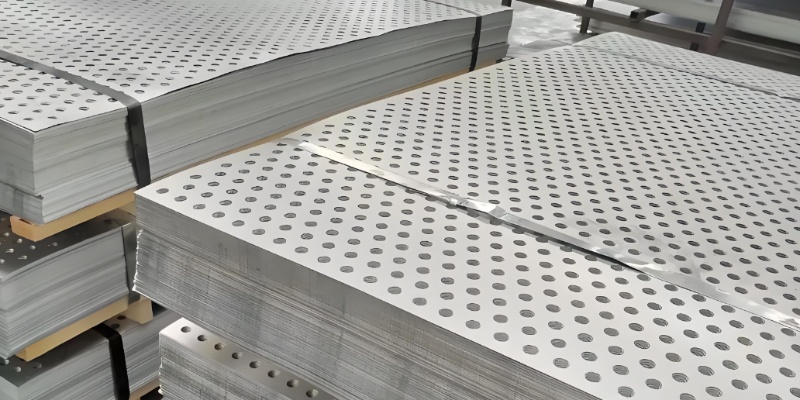

Stainless Steel Perforated Sheets

Corrosion Resistance: Stainless steel perforated sheets are renowned for their exceptional resistance to corrosion, attributed to the formation of a dense chromium oxide layer on the surface. This makes them ideal for use in humid or acidic environments.

Strength and Hardness: With high mechanical strength and hardness, stainless steel maintains structural integrity under significant pressure or impact. Grades such as 304 and 316 offer varying properties to suit different applications.

High-Temperature Performance: Certain stainless steels, like 310S, exhibit excellent oxidation resistance and structural stability at elevated temperatures, making them suitable for high-temperature equipment.

Applications: Ideal for food processing, pharmaceuticals, chemical industries, medical devices, and architectural decoration, especially where hygiene and cleanliness are paramount.

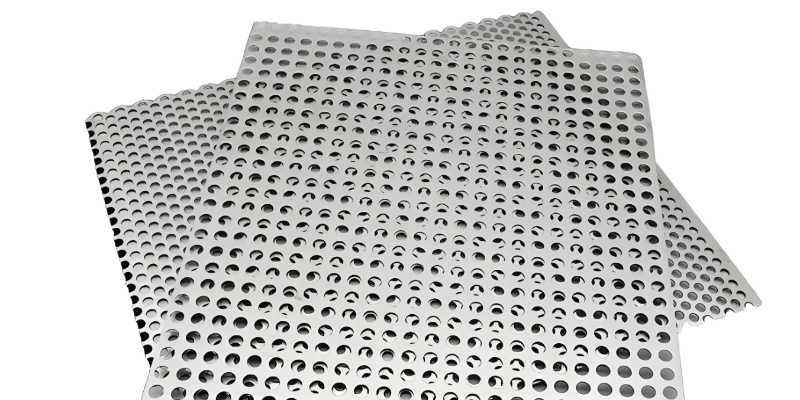

Lightweight: Aluminum's low density—approximately one-third that of steel—makes it an excellent choice for applications where weight reduction is essential, such as in transportation vehicles.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer, offering a degree of corrosion resistance. However, it may react in strong acidic or alkaline environments.

Thermal and Electrical Conductivity: Aluminum's superior thermal and electrical conductivity makes it suitable for heat exchangers, air conditioning systems, and electronic enclosures.

Malleability: Its ease of fabrication allows for the creation of complex shapes, beneficial in architectural and decorative applications.

Applications: Commonly used in building facades, ceilings, ventilation systems, and electronic device housings.

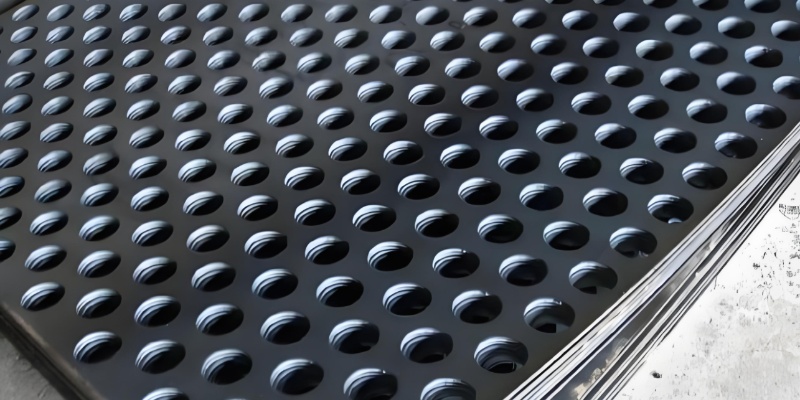

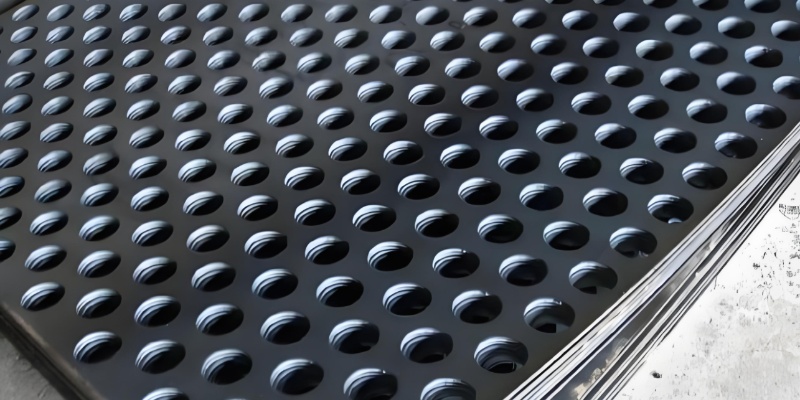

Corrosion Resistance: Galvanized steel sheets are coated with a layer of zinc, enhancing their resistance to corrosion. The zinc layer acts sacrificially, protecting the underlying steel from environmental factors.

Cost-Effectiveness: Offering a balance between performance and affordability, galvanized steel is a cost-effective alternative to stainless steel.

Processing Performance: Galvanized steel exhibits good formability, allowing for various processing methods, including stamping, bending, and welding.

Applications: Suitable for building facades, roofing, fencing, ventilation ducts, and agricultural facilities.

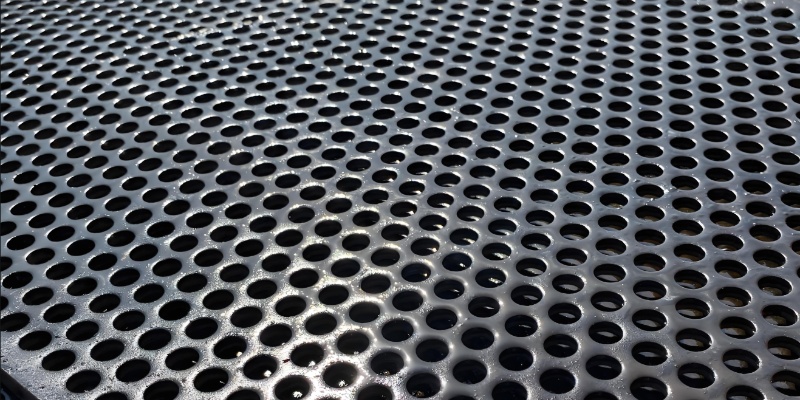

Carbon Steel Perforated Sheets

High Strength: Carbon steel perforated sheets boast high mechanical strength and toughness, capable of withstanding substantial loads and impacts. Variations in carbon content (low, medium, high) offer different mechanical properties.

Affordability: Compared to other materials, carbon steel is relatively inexpensive, making it a practical choice for budget-conscious projects.

Susceptibility to Rust: Without protective treatments, carbon steel is prone to oxidation and rust in humid environments. Preventative measures like painting or galvanizing are recommended.

Applications: Used in machinery protective covers, industrial filtration equipment, and structural components in construction.

Wear Resistance: Manganese steel is renowned for its exceptional wear resistance, making it suitable for high-abrasion environments. The presence of manganese enhances its durability and impact resistance.

Toughness: This material maintains excellent toughness, even under high-impact conditions, ensuring longevity in demanding applications.

Applications: Ideal for mining equipment, screening machinery, and other high-wear industrial applications.

Selecting the appropriate material for perforated metal sheets is crucial, as it directly impacts the performance, durability, and suitability of the end application. Understanding the distinct properties of each material enables informed decision-making to meet specific project requirements.