Circular Perforated Metal Mesh Per Square Meter Price – Complete Guide

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 14:37:24 Browse:

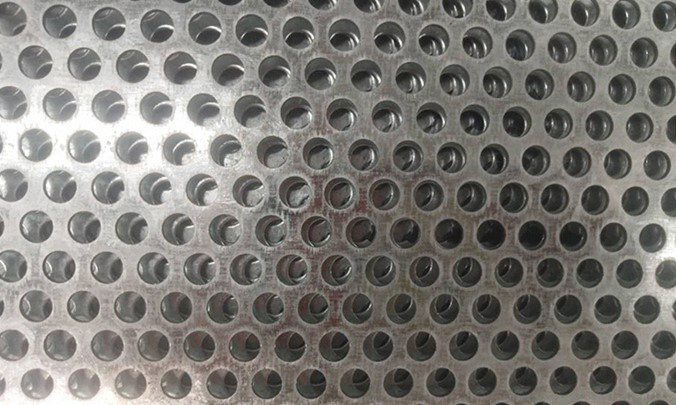

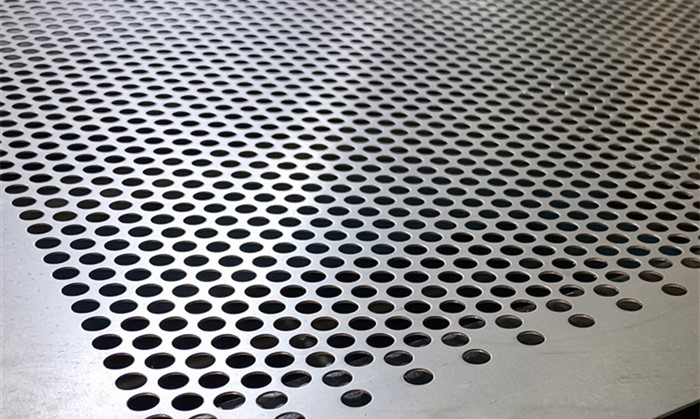

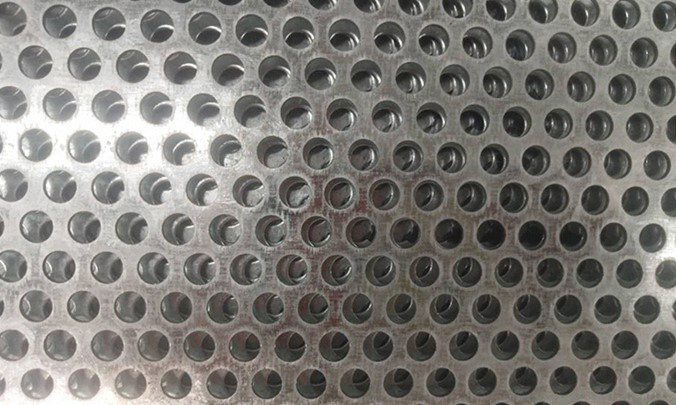

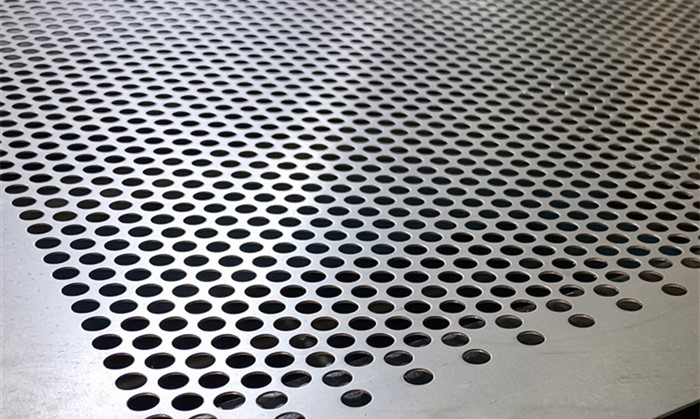

Circular perforated metal mesh is a net-like metal product manufactured by precision punching on high-accuracy CNC machines using customized molds. Made from premium quality sheet metal, this product features excellent wear resistance, a smooth surface, uniform hole distribution, and superior filtration capability. Due to these qualities, it is widely used across filtration, screening, soundproofing, decoration, and protective applications, playing a vital role in both industrial and architectural fields.

A Common Question: What’s the Price Per Square Meter?

One of the most frequently asked questions by users is:

How much does circular perforated metal mesh cost per square meter?

However, this is not a question with a simple, fixed answer. The price varies depending on multiple factors. Without detailed specifications, it is difficult for manufacturers to provide an accurate quote.

perforated metal mesh

Why Are Detailed Parameters Necessary for Pricing?

Circular perforated metal mesh comes in various specifications. The hole diameter, pitch, sheet thickness, material, and size all significantly influence the final cost. Below is a breakdown of how each factor affects the price per square meter:

1. Hole Diameter Impacts the Price

Circular perforated mesh can be customized with hole diameters ranging from 0.2mm to 300mm.

Smaller hole diameters require more advanced tooling and longer processing times, increasing production costs.

Larger hole diameters are easier and faster to process, thus lowering costs per square meter.

2. Hole Pitch Affects Production Efficiency

Hole pitch (the space between holes) impacts mesh density and production speed.

Smaller pitch means more holes per square meter, longer processing time, and higher manufacturing cost.

Larger pitch results in fewer holes, faster production, and reduced cost.

3. Sheet Thickness Determines Manufacturing Difficulty

The thickness of the metal sheet used directly correlates with production complexity and material cost.

Thicker sheets require higher punching force and cause more wear on tooling, leading to higher costs per square meter.

Common sheet thicknesses range from 0.3mm to 12mm, depending on application needs.

perforated metal mesh

4. Material Type Defines Raw Material Cost

The base metal used significantly affects the mesh price. Each material has its own market value.

Common materials include:

Mild steel: Budget-friendly, suitable for non-corrosive environments.

Galvanized steel: Better corrosion resistance, suitable for outdoor use.

Aluminum: Lightweight and corrosion-resistant, but more expensive than steel.

Stainless steel (e.g., 304, 316): Excellent corrosion resistance, used in food, medical, and chemical industries.

Copper, titanium, etc.: Specialty metals with much higher costs.

5. Sheet Size Influences Material Utilization

While the finished size of the circular perforated metal mesh can be customized, the raw sheet material generally comes in standard widths, such as:

1.0m, 1.25m, 1.5m

If the required finished width is, for example, 1.3m, a 1.5m wide sheet must be used. The unused material is considered waste and contributes to the cost per square meter. Therefore, non-standard sizes often lead to higher prices.

How to Get an Accurate Price Per Square Meter?

To receive an accurate quote for circular perforated metal mesh, please provide the following specifications:

Hole diameter (mm)

Hole pitch (mm)

Sheet thickness (mm)

Material type (e.g., stainless steel 304, aluminum, etc.)

Final product dimensions (length and width)

With this information, manufacturers can quickly calculate a fair and accurate price and offer expert product recommendations based on your needs.

perforated metal mesh

Final Thoughts

Circular perforated metal mesh is a versatile, cost-effective solution with broad industrial and decorative uses. However, pricing per square meter depends on numerous variables and should not be generalized. We highly recommend detailed communication with manufacturers to ensure you get the best product at the most accurate price.

If you're looking for high-quality, custom-made circular perforated metal mesh, feel free to contact our expert team. We’re ready to offer precise quotations and professional service tailored to your application.