What Are the Key Factors That Affect the Price of Perforated Panels?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-11 18:02:40 Browse:

Perforated panels are widely used in architectural decoration, industrial noise control, ventilation systems, safety enclosures, and more. The price per square meter of perforated panels can vary greatly depending on multiple factors. Understanding these variables will help buyers plan their budgets more effectively and choose the right product based on specific needs. In this article, we will break down the core factors that determine the cost of perforated panels, including material, thickness, hole type, and production complexity.

1. Material Type Is the Primary Price Driver

The base material of perforated panels is one of the most critical cost components. Different metals come with varying raw material costs:

Iron is one of the most economical options for perforated panels. It includes cold-rolled steel, hot-rolled steel, and galvanized steel. Cold-rolled sheets have a smooth finish and are suitable for precise applications. Hot-rolled steel is cheaper but has a rougher surface. Galvanized steel provides excellent corrosion resistance and is slightly more expensive.

Aluminum perforated panels are lightweight and resistant to corrosion. They are more expensive than iron panels and come in different series such as the 1000, 3000, 5000, 6000, and 7000 series. The 5000 series is widely used due to its strength and corrosion resistance, while the 7000 series is a high-end option with aerospace-grade performance.

Stainless steel offers premium quality for perforated panels. Common materials include 201, 304, and 316 stainless steel. Type 201 is economical and suitable for general indoor use. Type 304 is more durable and corrosion-resistant, making it the most commonly used grade. Type 316 provides superior resistance to chemicals and salt, making it ideal for marine and industrial environments, with the highest cost among the three.

perforated panels

2. Thickness Directly Impacts Material and Labor Costs

When the material and hole design are the same, panel thickness becomes a decisive factor in pricing:

Thicker panels require more material, thus increasing cost by weight.

Heavier panels take longer to process, reducing production efficiency.

Thicker materials demand more powerful machinery and greater labor input, which also raises the price per square meter.

Perforated panels are often priced by weight, not just area, so thickness is a major cost determinant.

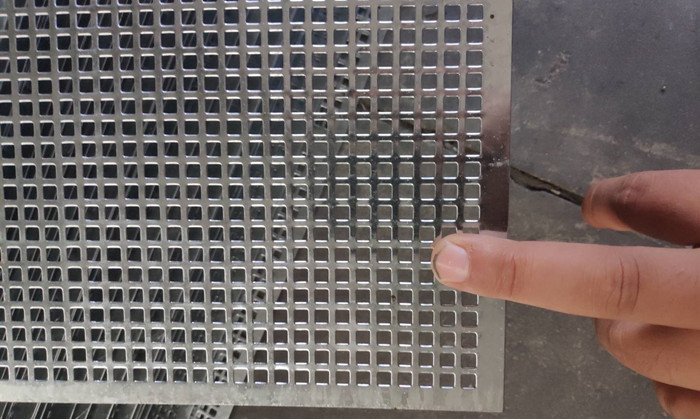

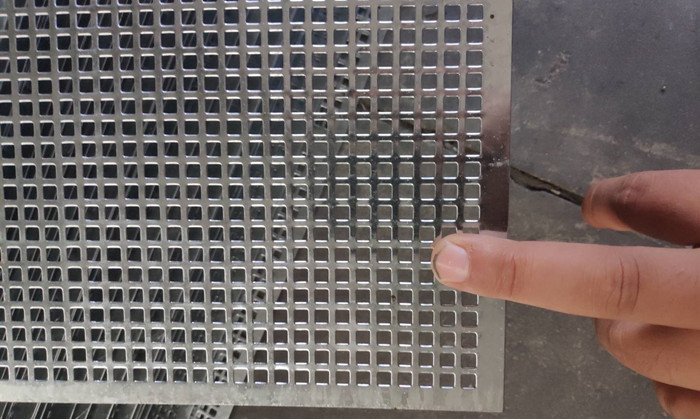

3. Hole Types Vary in Processing Complexity

Perforated panels come with a wide range of hole shapes, including standard and custom patterns. Common types include round holes, oval holes, long round holes, square holes, rectangular holes, and more intricate designs such as triangular holes, star-shaped holes, hexagonal holes, cross holes, plum blossom holes, fish scale holes, and crocodile mouth holes.

● Processing cost depends on the complexity:

Standard holes (round, square) use mature tooling and are cost-effective to produce.

Custom hole types (fish-scale or crocodile-mouth) involve additional labor and special dies. For example, fish-scale perforated panels do not drop material and create a 3D effect, increasing production cost.

Two-step processing like crocodile-mouth patterns require both punching and surface shaping, resulting in higher labor and machine costs.

perforated panels

4. Smaller Hole Sizes Increase Production Difficulty

The size of the holes directly affects production speed and tool durability:

Smaller holes require more frequent punching per square meter, slowing down production.

High precision and tighter tolerances are needed to maintain quality.

Tool wear increases with small hole patterns, which leads to higher operational costs.

So, for the same material and thickness, perforated panels with smaller holes will usually be priced higher.

5. Panel Size and Dimensions Influence Material Utilization and Handling

Standard sizes include 1m × 2m, 1.2m × 2.4m, and 1m × 20m rolls. Larger panels or continuous roll formats require special handling during transport and processing. Moreover, how the holes are laid out (nesting or spacing) affects material utilization, which can influence the final quotation.

perforated panels

Conclusion: Provide Full Specifications for an Accurate Quotation

The price of perforated panels per square meter is influenced by several key factors: material, thickness, hole type, hole size, and panel size. For a precise quote, it’s recommended to provide detailed specifications, including material grade, dimensions, hole shape and size, and quantity.

If you need assistance in selecting the right perforated panels or wish to obtain a customized quote, please feel free to contact us via the phone number listed at the bottom of our website. Our professional team is ready to offer one-on-one consultation and help you find the best solution.

perforated panels