Production Deformation Causes and Solutions for Crocodile Mouth Safety Grating

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-26 14:45:04 Browse:

1. Production Process of Crocodile Mouth Safety Grating

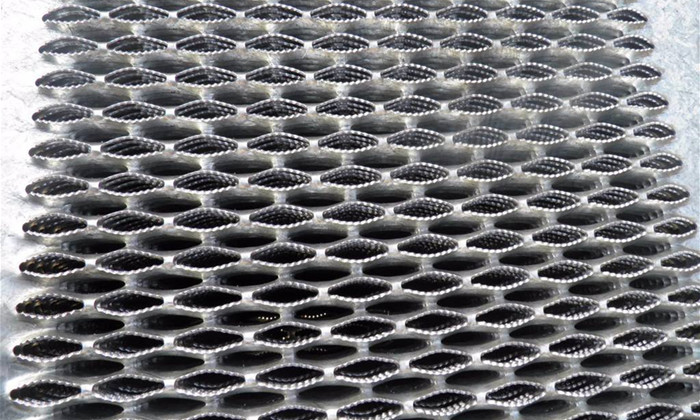

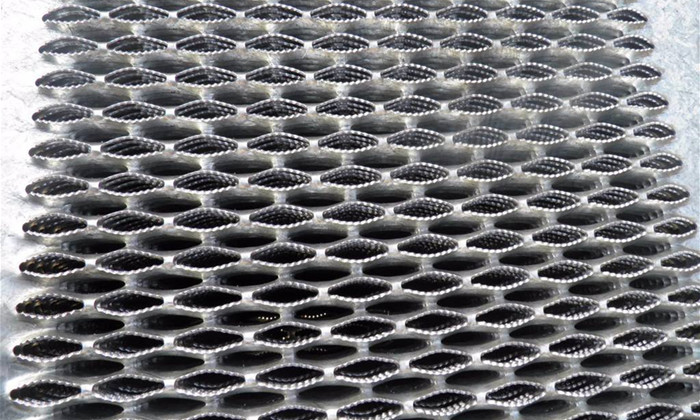

Crocodile mouth safety grating is a type of anti-slip material widely used in industrial and construction settings. It offers excellent slip resistance and durability.

Typically, it is made from high-quality low carbon steel or stainless steel sheets. The manufacturing process involves punching serrated holes into the metal sheet, followed by cutting and bending to achieve the desired dimensions and shapes.

Finally, a hot-dip galvanizing process is applied to enhance corrosion resistance and extend the lifespan of the crocodile mouth safety grating.

2. Main Causes of Deformation During Production

Large-Area Punching Causes Thermal Deformation

During the punching process—especially when perforating large areas—the metal sheet can undergo localized heating, leading to stress concentration and subsequent warping or deformation.

Rough Punching Mold Surface

If the punching mold surface is not well-polished, its rough texture increases friction during the stamping process, which can cause surface scratches and result in deformation of the grating.

Lack of Lubrication

Failing to use lubricant during punching can increase the coefficient of friction between the sheet and the mold. This not only accelerates mold wear but also makes the sheet more susceptible to deformation.

Crocodile mouth safety grating

3. Solutions and Preventive Measures

Control Punching Area

It’s important to reasonably limit the punching area when designing the perforation pattern. Avoid large-area punching in one go. For products requiring large perforated surfaces, it's advisable to inform clients in advance about the risk of deformation and discuss viable alternatives.

Optimize Mold Surface Treatment

Regular polishing of the punching mold ensures a smooth surface, reducing friction during stamping and thereby minimizing the likelihood of deformation in the crocodile mouth safety grating.

Use Proper Lubricants

Applying the right amount of lubricant evenly across the metal sheet surface before punching can effectively reduce friction, protect the mold, and prevent deformation during production.

4. Conclusion

Deformation in crocodile mouth safety grating is a common but controllable issue during production.

By managing perforation layout, improving mold surface finish, and using appropriate lubrication, manufacturers can significantly reduce the risk of sheet warping, thus ensuring product quality and meeting customer expectations.

In actual operations, flexible application of these methods based on the specific production scenario will lead to optimal results.