2025-01-10

2025-03-04

2025-06-14

2025-05-13

2025-05-19

2025-05-21

2025-04-11

2025-06-14

2025-05-19

2025-06-07

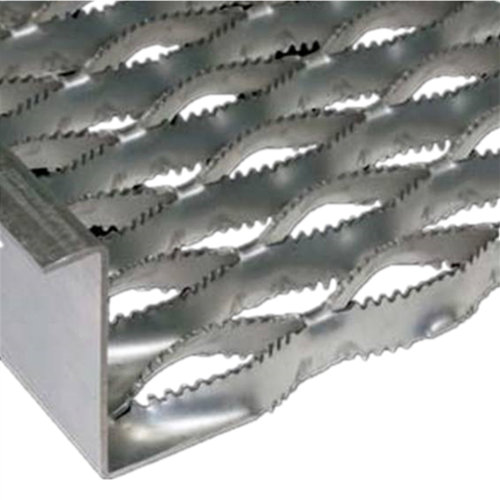

Stair Grip Strut Safety Grating

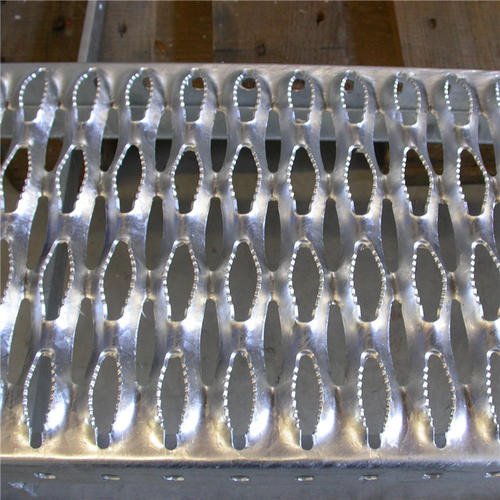

Aluminium Grip Strut Safety Grating

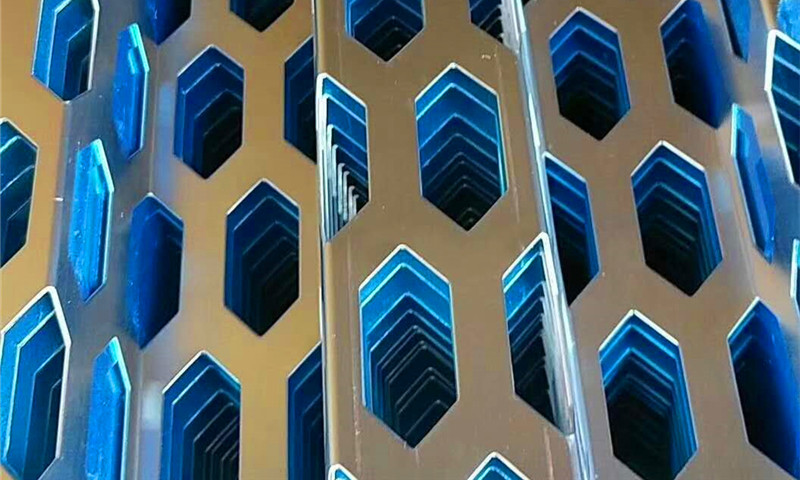

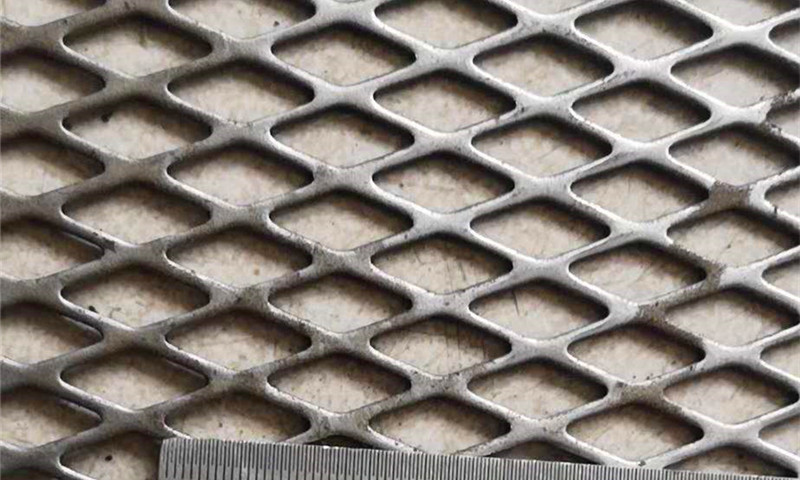

Carbon Steel Punched Metal Plate

Walkway Grip Strut Safety Grating

Anti-skid Stair tread plate

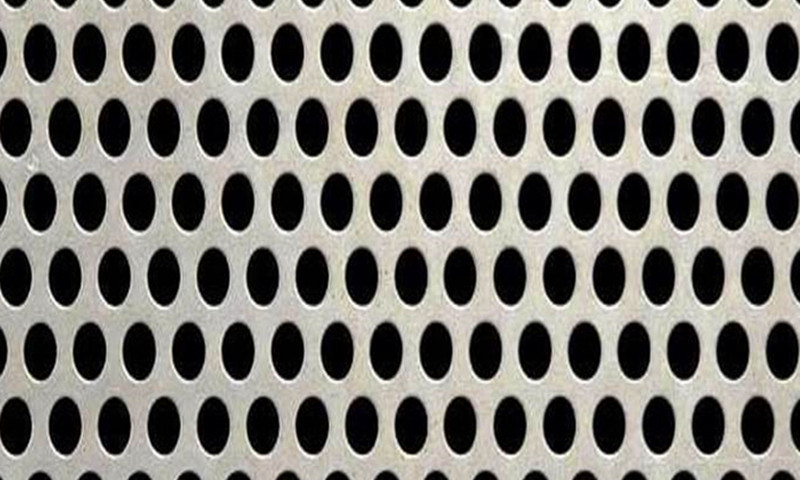

Slotted Hole Sieve Sheet

Stainless Steel Grip Strut Safety Grating

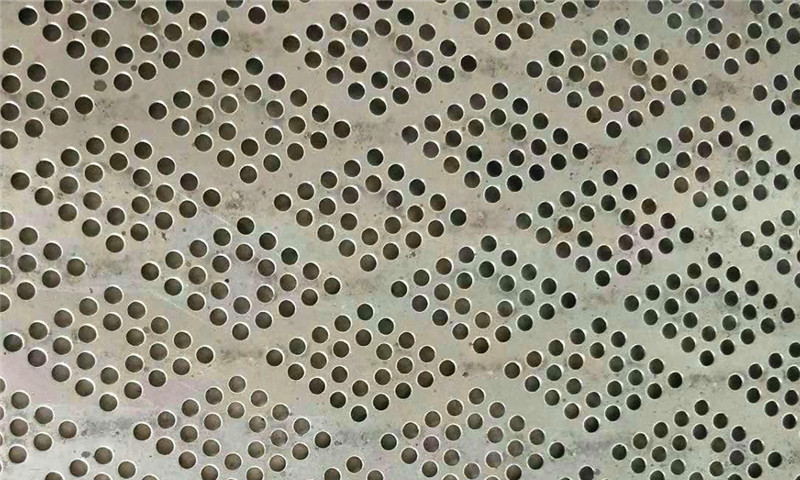

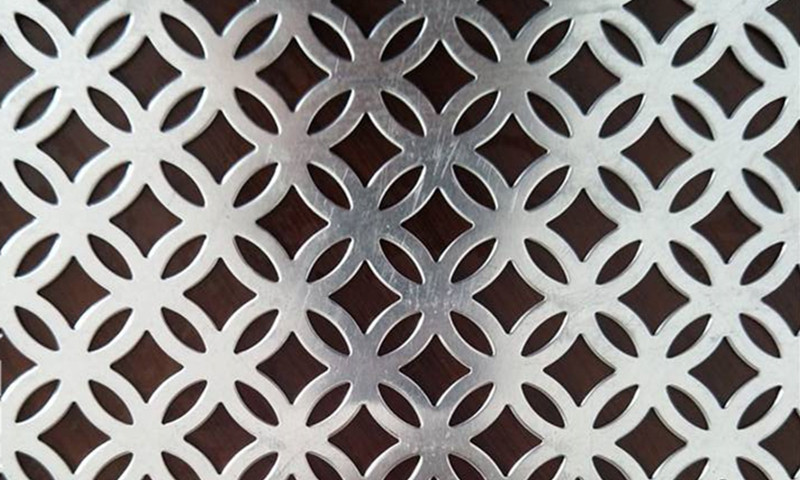

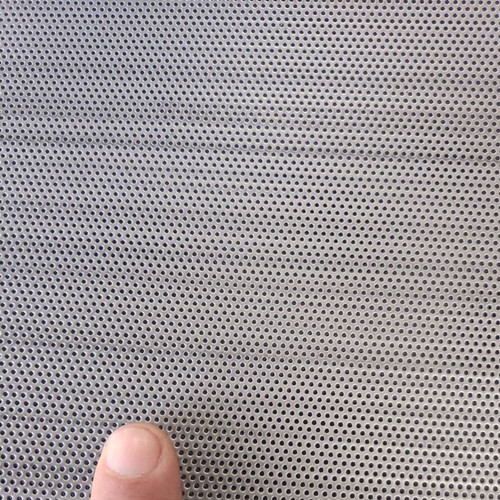

Perforated Sieve Sheet

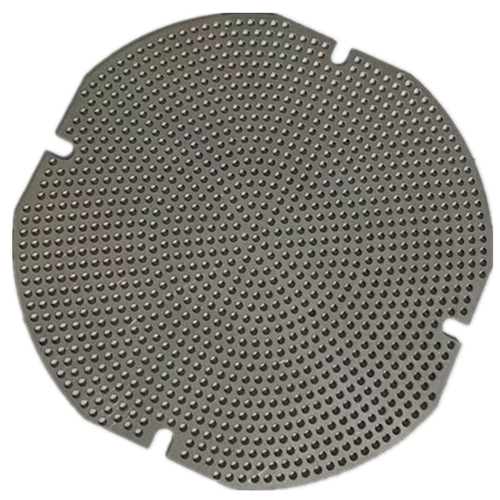

Concentric circular sieve plate

Convex Hole Anti-skid Plate

Grip Strut Safety Grating

Small Hole Sieve Sheet

Micropore Sieve Sheet

Galvanized Safety Grating

Fisheye Anti-Slip Grating