What is Perforated Round Hole Mesh? – Comprehensive Guide to Metal Perforated Sheets, Materials, and Applications

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-04-22 14:40:22 Browse:

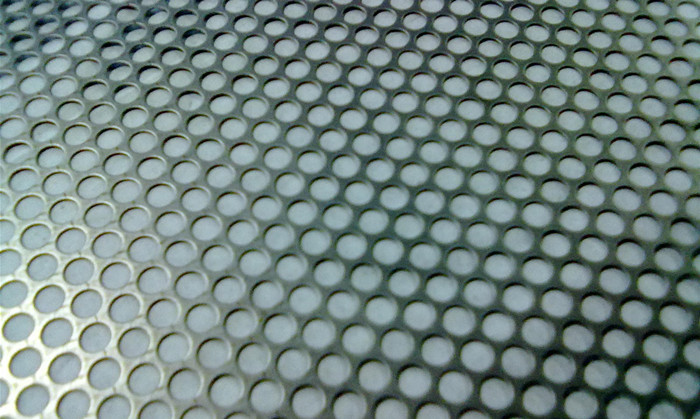

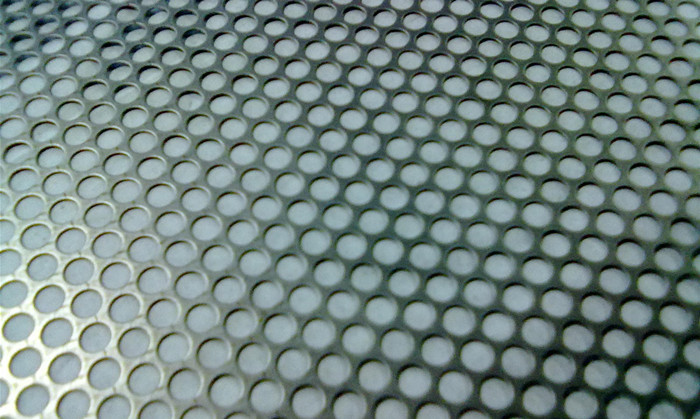

Perforated Round Hole Mesh is a functional type of metal perforated sheet made by continuously punching regular round holes into metal plates using CNC punching machines combined with specialized round-hole dies. Thanks to precise punching techniques and flexible die designs, perforated round hole mesh offers a neat, attractive appearance and holds significant value for decoration, beautification, sound insulation, filtration, anti-slip, ventilation, and many other applications.

I. Production Process and Core Advantages

Material Preparation and Flattening:

Selected cold-rolled steel, hot-rolled steel, aluminum sheets, or stainless steel plates are cut and leveled to ensure material flatness.

CNC Precision Punching:

Specialized round-hole molds are installed, and the CNC system accurately controls punching position and hole size, achieving uniform hole shapes and tidy arrangements.

Deburring and Flattening:

After punching, surface burrs and hole edges are treated, and minor warping caused by punching is corrected to ensure flatness of the finished product.

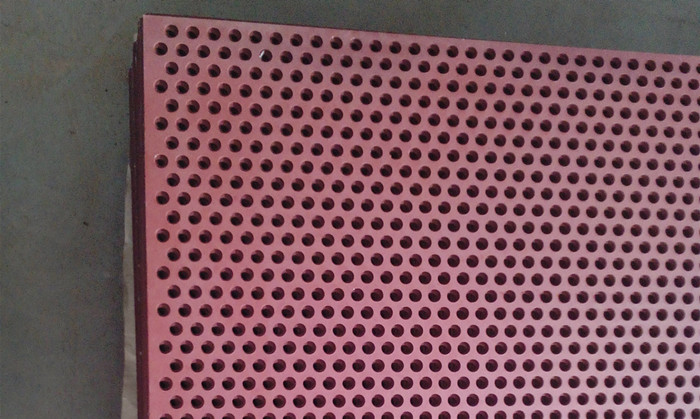

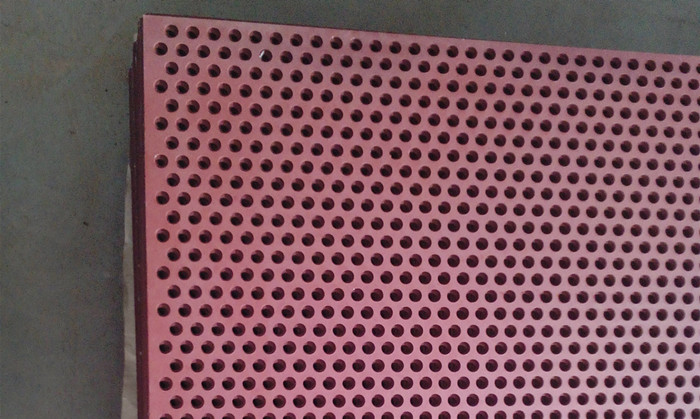

Surface Treatment:

Depending on the application environment and decorative needs, surface treatments such as powder coating (polyester powder), baking paint (fluorocarbon paint), hot-dip galvanizing, cold galvanizing, or aluminum anodizing can be selected to enhance corrosion resistance and aesthetics.

Core Advantages:

Uniform Hole Distribution: High precision CNC punching ensures consistent hole sizes and center distances.

Lightweight Yet Strong: Reduces weight by 20%–60% compared to solid plates while maintaining sufficient structural strength.

High Open Area Ratio: Adjustable open area ratio (generally 10%–60%) balances breathability and load-bearing capacity.

Customizable Craftsmanship: Hole diameters range from 0.2 mm to 300 mm; sheet thickness options from 0.1 mm to 20 mm.

Eco-Friendly and Durable: Metals are recyclable; treated surfaces are weather-resistant and corrosion-proof.

II. Common Materials and Their Characteristics

Carbon Steel Perforated Mesh:

Sheet Sources: Commonly cold-rolled sheets, hot-rolled sheets, galvanized sheets, or high-manganese steel plates.

Performance Advantages: High strength, low cost, suitable for load-bearing structures and low-corrosion environments; colorful finishes achievable with powder coating or baking paint.

Aluminum Alloy Perforated Sheets:

Grade Coverage: Wide range from 1000 to 7000 series aluminum sheets.

Features: Lightweight, corrosion-resistant, excellent decorative performance; commonly treated with anodizing or powder coating, ideal for curtain walls and outdoor decorations.

Stainless Steel Perforated Mesh:

Common Materials: 201, 304, 316, 409, 430 stainless steel plates.

Functional Advantages: Excellent high-temperature resistance, corrosion resistance, and rustproof capabilities, widely used in food, pharmaceutical, chemical, marine, and humid environments.

III. Core Application Scenarios

Architectural Decoration:

Curtain wall facades, interior ceilings, partition screens, stair handrail protection — achieving both ventilation and modern decorative effects.

Acoustic Treatment:

Conference rooms, cinemas, concert halls — combined with sound-absorbing materials to significantly improve sound insulation and acoustic performance.

Ventilation and Heat Dissipation:

Server cabinets, fan guards, air conditioner covers — regular round holes ensure excellent airflow and cooling efficiency.

Anti-Slip and Protection:

Stair treads, platform gratings, industrial flooring — effectively increasing friction and ensuring safety.

Filtration and Screening:

Food production, chemical separation, liquid filtration, powder screening — customizable aperture sizes to match particle dimensions.

Municipal and Transportation:

Noise barriers, bridge protective nets, subway ventilation openings, automobile windshields — combining functionality with aesthetics.

IV. Custom Solutions and Selection Recommendations

Hole Type and Arrangement:

Supports standard straight-row and staggered layouts; non-standard custom designs are available based on drawings to achieve unique aesthetics.

Surface Treatment Selection:

For outdoor or humid environments, recommend using 304/316 stainless steel or 5-series aluminum combined with fluorocarbon coating or anodizing.

Balancing Load-Bearing and Open Area Ratio:

Higher open areas reduce load-bearing capacity; this can be reinforced by increasing sheet thickness or optimizing center distances.

Acoustic Application Enhancements:

For spaces requiring high sound insulation, back-layer with sound-absorbing cotton or polyester fiber soundproof mats to further boost noise reduction.

Maintenance and Lifespan:

Regularly clean surface dust and contaminants; intact coatings can sustain over 10 years of service life.

V. Conclusion and Service Support

Perforated Round Hole Mesh, with its precision-engineered holes, diversified materials, flexible customization options, and wide functionality, has become the preferred choice in architectural decoration, industrial manufacturing, and municipal engineering. We provide one-stop services covering material selection, punching layout, surface treatment, and post-processing to ensure each perforated sheet precisely meets your project requirements.

For technical evaluations, sample requests, or professional advice, feel free to contact our technical team — we are ready to tailor the best solution for you!