Iron Plate Perforated Sheet Introduction: Types, Specifications, Applications, and Packaging

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-11 16:00:06 Browse:

Iron plate perforated sheet, also known as perforated iron plate, perforated steel plate, or perforated metal sheet, is a widely used metal product in industrial and architectural applications. It is manufactured using CNC punching machines to create precise hole patterns on iron sheets. Thanks to its flat surface, attractive appearance, strong structure, reusability, and good durability, it has become a popular choice across many industries.

1. Material and Common Specifications of Iron Plate Perforated Sheets

Iron plate perforated sheets are typically made from standard cold-rolled iron plates. This material provides high rigidity and strength while maintaining excellent formability and processability, making it suitable for customized needs.

Common specifications include:

Coil sheet: 1m width × 20m length

Flat sheet: 1m × 2m, 1.2m × 2.4m

Custom sizes and shapes available upon request

This flexibility in size and shape makes iron plate perforated sheets easy to integrate into various project requirements.

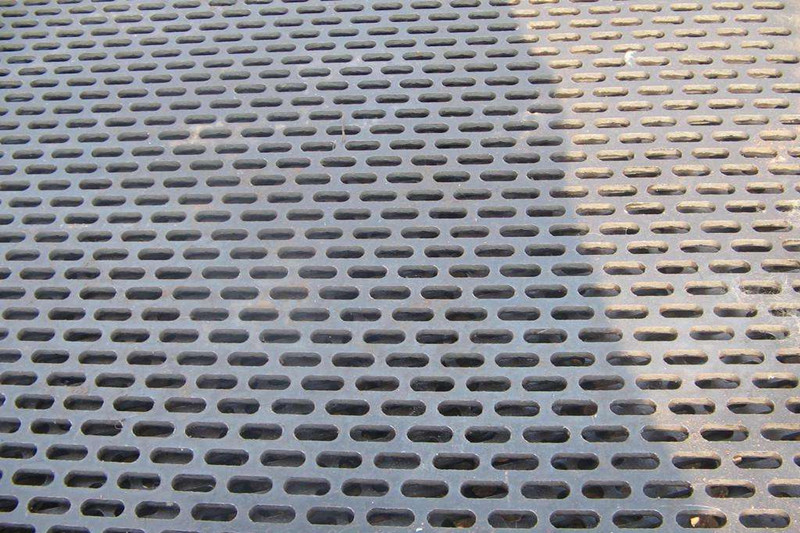

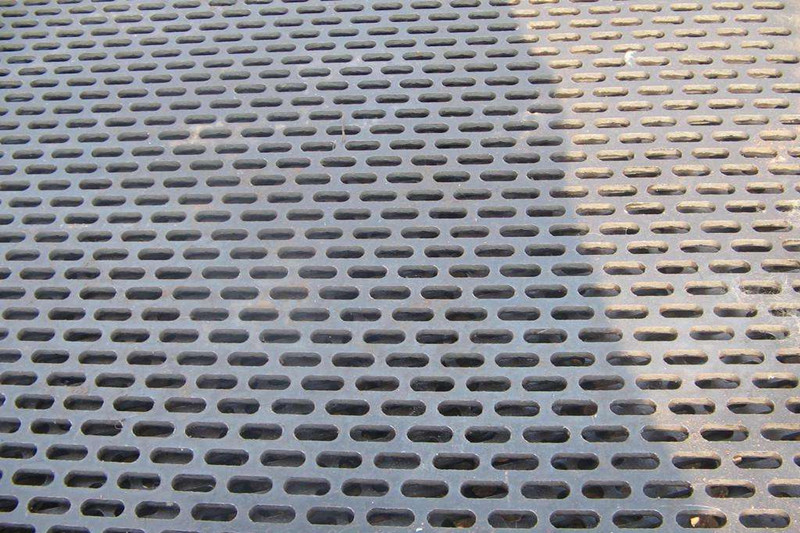

Iron plate perforated sheet

2. Hole Patterns and Functional Features

The performance and use cases of iron plate perforated sheets vary depending on the hole type and arrangement. Below are the common types:

60° Staggered Round Hole

One of the most popular arrangements, forming a honeycomb pattern. It features a high open area, strong structural integrity, and an eye-catching design. Ideal for screening and ventilation.

45° Staggered Round Hole

Offers an alternative visual and structural option compared to the 60° arrangement. Suitable for applications with unique visual or space requirements.

90° Straight Round Hole

A straight row pattern that delivers symmetry and uniformity. Although it has lower resistance compared to staggered holes, it's often used for light-duty screening or decorative purposes.

Square Hole

Square holes offer a higher open area than round holes and are commonly used where better visibility or ventilation is required—such as display shelves, retail counters, and machine guards. However, compressive strength is slightly reduced.

Elongated Round Hole (Staggered)

Mainly used for solid material screening. The staggered layout improves efficiency and durability in heavy-duty applications.

Elongated Round Hole (Straight)

Ideal for vibrating screens and fluid filtration systems, this pattern supports excellent drainage and airflow.

Hexagonal Hole

Provides the highest open area and modern aesthetics. Commonly used in decoration, ventilation, and lightweight screening tasks.

Iron plate perforated sheet

3. Applications of Iron Plate Perforated Sheets

Thanks to its moderate pricing and high functionality, iron plate perforated sheet is widely used in various sectors:

Mining & Material Screening: For separation and filtering of minerals, stones, and coal

Medical Industry: For pharmaceutical screening and sterile ventilation systems

Grain Processing: Used in granaries for ventilation, drying, and separation of grains

Architecture & Interiors: As ceiling panels, acoustic barriers, and decorative partitions

Mechanical Safety: For equipment enclosures, safety guards, and anti-injury covers

Soundproofing Projects: Applied in sound absorption and noise control systems

Environmental Systems: As support mesh in dust collectors and filtration equipment

4. Packaging Options for Iron Plate Perforated Sheets

To ensure safe transport and product integrity, we offer several packaging solutions tailored to the customer's requirements:

Manual Packaging

Smaller sheets can be wrapped in woven bags—cost-effective and convenient.

Wooden Pallet Packaging

Suitable for large or bulk products. Provides stability and protection during shipping. Extra charges may apply.

Foam and Protective Wrapping

For surface-sensitive or export-grade products, layered foam and protective film packaging ensures scratch-free and deformation-free delivery.

Iron plate perforated sheet

Conclusion

Iron plate perforated sheet is a highly versatile metal solution that offers outstanding strength, airflow, visibility, and decorative potential. Whether you need it for heavy-duty screening, mechanical protection, or aesthetic enhancement, we provide a wide range of specifications, hole designs, and custom services to meet your needs.

Contact us today for more product details or to request a customized quote. Our team is ready to offer you professional support and high-quality service.