Perforated Grip Strut Safety Grating – Custom Industrial Safety Solutions

Made in China • Global Supply • Custom Manufacturing

Product Overview

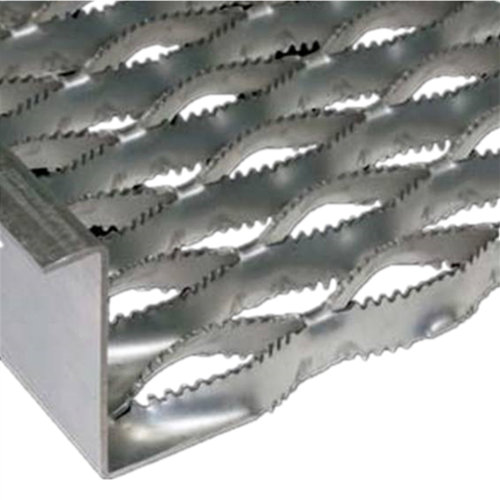

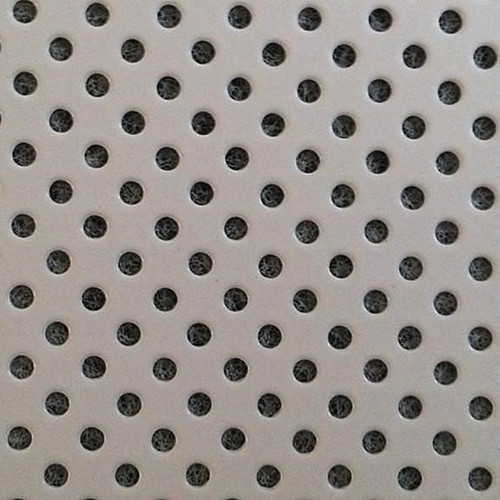

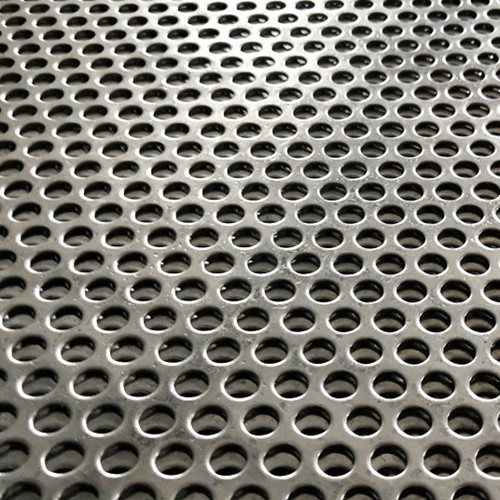

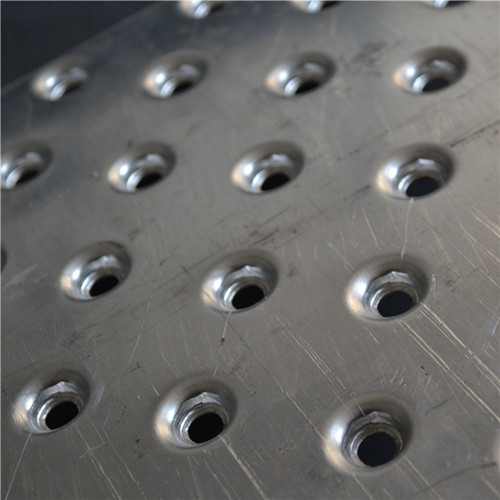

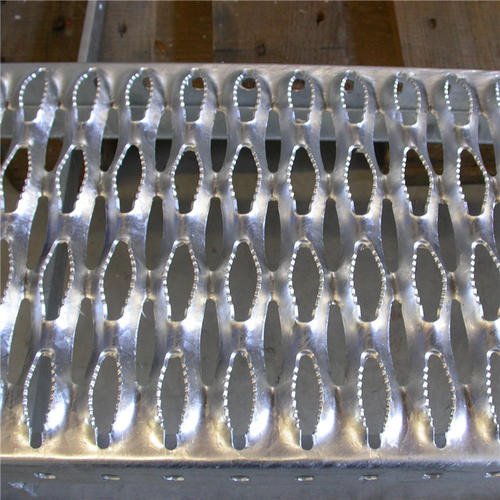

Perforated Grip Strut Safety Grating utilizes CNC punching technology to create raised-dimple patterns on metal sheets, significantly boosting surface friction. Engineered for slippery environments like wastewater treatment plants and steel platforms, it delivers unmatched slip resistance in oily or wet conditions.

Customizable Specifications

Tailor every detail to your project needs:

Material Options

Cold Rolled Steel • Hot Rolled Steel • Galvanized Steel

Manganese Steel • Aluminum • Stainless Steel (201/304/316L)

Engineering Parameters

Thickness: 1.0mm - 3.5mm | Standard Sizes: ≤1.5m(W) × ≤4m(L)

Non-standard cutting supported

Pattern Designs

Crocodile Mouth • Round Drum patterns (Standard)

Custom patterns from your CAD drawings

Surface Finishes

Spray Painting • Fluorocarbon Coating • Powder Coating

Anodizing • Electrolytic Polishing

Key Performance Features

Superior Slip Prevention

Dimpled perforations grip footwear firmly, even when submerged in oil or water.

Extreme Durability

High-strength metals with corrosion-resistant treatments endure harsh chemicals, humidity, and temperatures from -30°C to 150°C.

Eco-Conscious Manufacturing

100% recyclable materials and low-waste production support sustainable operations.

Industrial Applications

• Water Treatment: Walkways in sewage plants, pool edge guards

• Industrial Platforms: Steel structure access ways, maintenance catwalks

• Factory Automation: Conveyor transition zones, robotics workcells

• Heavy Industry: Chemical plant flooring, mining equipment steps

Technical Support & QC

Custom Workflow:

Consultation → Design Proof → Sample Approval → Mass Production

Precision Manufacturing:

• CNC punching (±0.2mm tolerance)

• Complies with industrial slip-resistance standards

• Third-party inspection accepted

Request a Quote

Provide details below for fast pricing:

▸ Application environment

▸ Material/Thickness specifications

▸ Dimensions (L×W×Thickness)

▸ Surface treatment

▸ Monthly volume needs

Contact: 342096438@qq.com

2025-01-10

2025-06-14

2025-05-19

2025-05-21

2025-05-19

2025-05-13

2025-03-04

2025-06-07

2025-04-11

2025-06-14

Stainless Steel Grip Strut Safety Grating

Metal Safety Grating

Convex Hole Anti-skid Plate

Perforated Sieve Sheet

Stair Grip Strut Safety Grating

Grip Strut Safety Grating

Carbon Steel Grip Strut Safety Grating

Heavy Duty Perforated Screens

Circular Hole Sieve Sheet

Galvanized Screening Plate

Stainless Steel Sieve Sheet

Fisheye Anti-Slip Grating

Carbon Steel Perforated Sheet

Galvanized Safety Grating

Walkway Grip Strut Safety Grating