Why Stainless Steel Perforated Sheets Are More Difficult to Process

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-16 15:13:40 Browse:

Stainless steel perforated sheets are widely used in architectural decoration, mechanical equipment, filtration, and separation applications due to their corrosion resistance, high strength, and sleek appearance. However, compared to materials like carbon steel or aluminum alloys, stainless steel perforated sheets present more processing challenges, such as shortened tool life, excessive burrs, and reduced efficiency. Below, we explore the core reasons behind these difficulties from both material characteristics and manufacturing perspectives, and suggest practical countermeasures.

1. Material Hardness and Structural Characteristics

1.1 High Hardness of Austenitic Structure

Stainless steel perforated sheets typically use austenitic grades like 304 and 316, which offer excellent corrosion resistance and ductility—but also have significantly higher hardness than carbon steel.

During the punching process, the die applies high-pressure shear to the sheet, concentrating stress in localized areas and causing strain hardening, which further increases the hardness around the punched zones.

1.2 Strain Hardening Accelerates Tool Wear

With repeated punching, the material becomes work-hardened at the contact zones. If the punch tool interacts with these hardened zones frequently, wear and tear on the cutting edge are significantly increased.

This leads to a noticeably reduced punch life, requiring frequent regrinding or replacement of tools, which raises manufacturing costs.

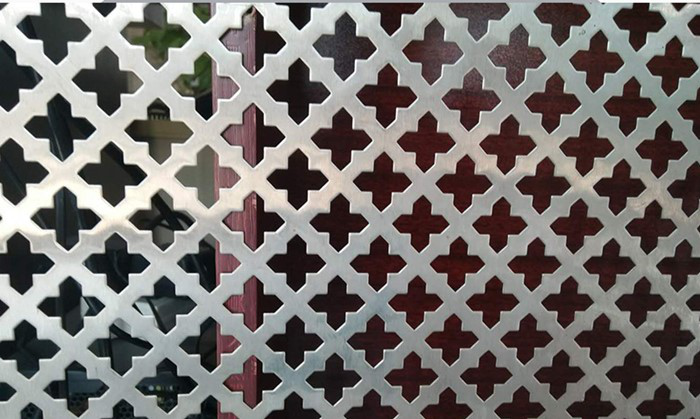

Stainless steel perforated sheet

2. Tool Wear from High Cutting Temperatures

2.1 Heat Concentration During Cutting

Stainless steel has low thermal conductivity. The friction and deformation heat generated during punching cannot dissipate quickly, causing the punch edge to reach very high temperatures.

Under such conditions, the tool’s hardness may drop, and thermal brittleness may occur, making the tool edge more prone to chipping or cracking.

2.2 Friction and Adhesion Issues

At high temperatures, stainless steel tends to adhere to the punch surface, creating burrs or “built-up edges.”

These adhesions increase the coefficient of friction, which further accelerates tool wear and negatively impacts the surface quality of the punched sheet.

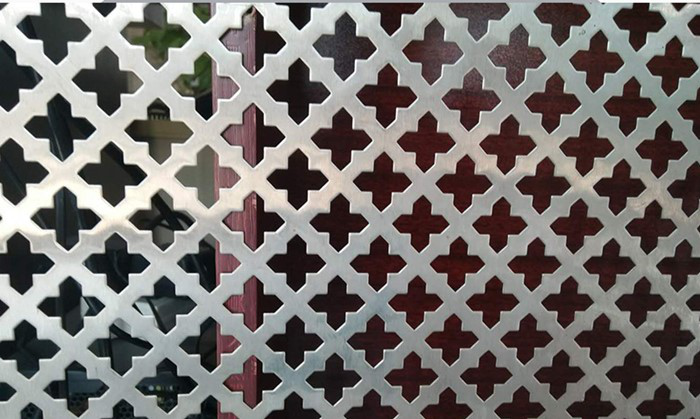

Stainless steel perforated sheet

3. Recommendations to Improve Processing Quality

3.1 Use High-Quality Punch Materials and Surface Treatments

Choose punches made from high-speed steel (HSS), carbide, or apply coatings like TiN or TiAlN to improve wear resistance and heat resistance.

Regular tool maintenance, including recoating or heat treatment, can extend tool lifespan.

3.2 Optimize Processing Parameters

Control punching force and speed to avoid deep cuts in a single stroke. Consider layered punching or multi-stage processing to reduce single-point impact.

Ensure appropriate clearance between punch and die to achieve smooth shear surfaces and minimize burrs.

3.3 Enhance Cooling and Lubrication

Apply suitable cutting fluids at the punching site to reduce tool temperature and minimize material adhesion.

For large-scale production, consider air or water cooling systems to maintain stable temperatures and improve process consistency.

Conclusion

Despite the challenges in processing stainless steel perforated sheets—such as higher material hardness and thermal concentration—manufacturers can achieve high-quality results by upgrading punch materials, fine-tuning processing parameters, and improving cooling and lubrication. These strategies not only help ensure the quality of the final product but also significantly enhance production efficiency and reduce overall tool costs. We hope this article offers practical insights for industry professionals and operators.