Stainless steel perforated sheet how much is a piece

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-15 11:32:13 Browse:

The market price for a stainless steel perforated sheet can range from just a few dollars to over a thousand dollars per panel, depending on size, thickness, perforation style, and material grade. To help you quickly understand and compare costs, this guide breaks down pricing tiers, the main factors that influence cost, and practical purchasing suggestions.

1. Price Range Overview

Under common specifications, prices for a stainless steel perforated sheet typically fall into three categories:

Economy Grade (small panel, light gauge): US$3–$12 per sheet

Standard Grade (up to 1 m × 2 m, 1.0 mm–2.0 mm thickness): US$12–$45 per sheet

Premium Custom (oversized panels, ≥ 3.0 mm thickness, high‑grade alloy): US$45–$200+ per sheet

These ranges are indicative; actual quotes depend on order volume, surface finish (brushed, mirror, powder‑coated), and shipping costs.

2. Key Factors Influencing Price

2.1 Panel Size

Area: Larger panels require more raw material and can generate higher scrap loss, increasing the unit cost for each stainless steel perforated sheet.

Edge treatment: Custom sizes may require welded seams or reinforced borders, adding to manufacturing costs.

2.2 Material Thickness

Standard gauges: 1.0 mm, 1.5 mm, and 2.0 mm are most common. Each additional 0.5 mm typically raises material costs by 15–25%.

Structural needs: For load‑bearing applications such as stair treads or platforms, 3.0 mm or thicker panels are recommended, which drives the price upward.

2.3 Stainless Steel Grade

201 / 430 Grades (economy): Basic corrosion resistance, ideal for dry indoor environments; lowest pricing.

304 Grade (standard): Excellent corrosion resistance and workability; the most widely used stainless steel perforated sheet option.

316 Grade (premium): Contains molybdenum for superior acid, alkali, and chloride resistance; suited to marine or chemical settings; premium pricing.

Specialty grades (e.g., 409, duplex): Tailored for high‑temperature or sulfurous environments, pricing varies with alloy composition and processing methods.

2.4 Perforation Pattern & Processing

Hole type: Round, square, slot, or custom shapes; custom dies and lower throughput raise costs.

Open area ratio: Higher open‑area percentages require more punching operations, adding to labor and tool wear.

Surface finishing: Options like bead‑blasting, brushing, or powder‑coating improve appearance and durability but add 10–30% to the base price.

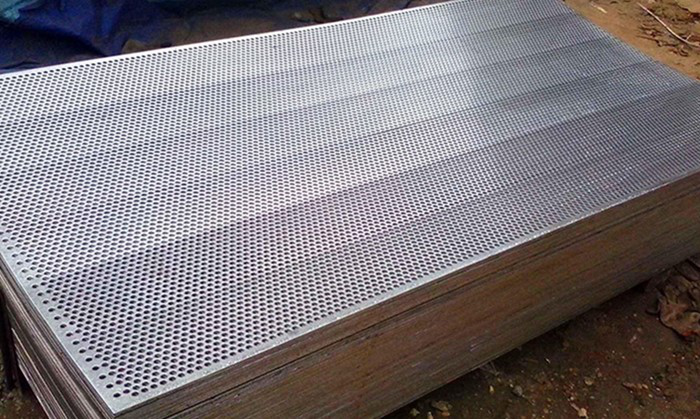

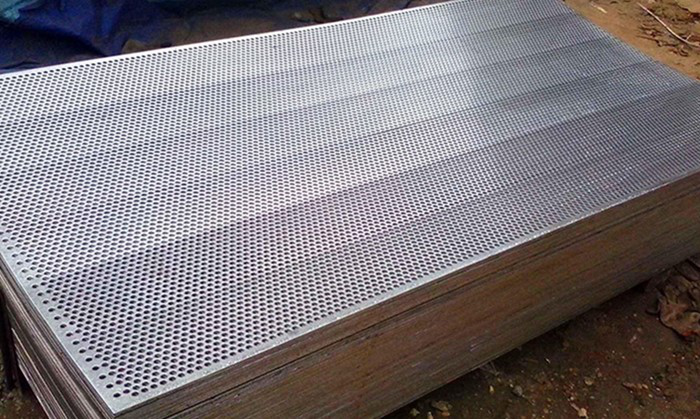

Stainless steel perforated sheet

3. Purchasing & Procurement Suggestions

Define Your Application Clearly

Identify whether the stainless steel perforated sheet will be used indoors or outdoors, in wet or dry conditions, and whether it must bear weight. This ensures you choose the right grade and gauge without over‑ or under‑specifying.

Compare Multiple Suppliers

Obtain quotes from at least three reputable fabricators. Compare material grades, manufacturing processes, lead times, and post‑sale support to find the best value.

Leverage Bulk Discounts

Smaller runs offer flexibility but carry higher per‑unit costs. Ordering larger batches often unlocks volume discounts and reduces shipping overhead—negotiate with your supplier for the best deal.

Inspect Upon Delivery

Upon receipt of your stainless steel perforated sheet, verify panel flatness, hole consistency (diameter and edge burrs), and surface finish quality. Confirm all meet your contract specifications before acceptance.

By understanding these price drivers and following our procurement tips, you’ll be well‑equipped to select and purchase the right stainless steel perforated sheet for your project. For tailored quotes or technical consultations, feel free to reach out—our team is ready to support you with expert guidance and comprehensive service.