Why the Thickness of Stainless Steel Perforated Sheets Affects Production Speed

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-10 21:28:36 Browse:

In the manufacturing of stainless steel perforated sheets, the thickness of the material plays a key role in determining the overall production speed. Many customers notice that thicker sheets take significantly longer to produce compared to thinner ones, even when using the same perforation techniques. So why does this happen? Let’s explore the technical reasons behind this phenomenon.

The Relationship Between Thickness and Production Speed

The production of perforated sheets relies on punching equipment to create precise holes in the stainless steel plates. The thicker the sheet, the more punching force is required. However, the punching machine has a fixed maximum punching pressure, which becomes a limiting factor.

When processing thin sheets, the machine can punch many holes at once, increasing efficiency. In contrast, with thicker sheets, the machine must reduce the number of holes punched in a single operation. In some cases, it may even take multiple punching actions to complete one hole. Naturally, this extends the production time and lowers the production speed.

The Limitation of Punching Pressure

A punching machine is the core of stainless steel perforated sheet manufacturing, and its rated punching pressure determines how many holes it can process within a specific time frame.

As the sheet thickness increases, the force needed per hole rises. Although the machine might be capable of handling higher pressures, manufacturers often choose to operate below the maximum to preserve the equipment and extend tool life. This conservative approach involves reducing punching speed, using fewer punches, or punching in stages—all of which contribute to slower production.

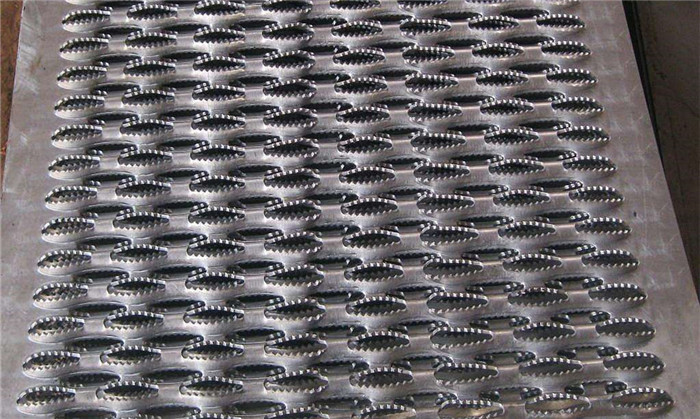

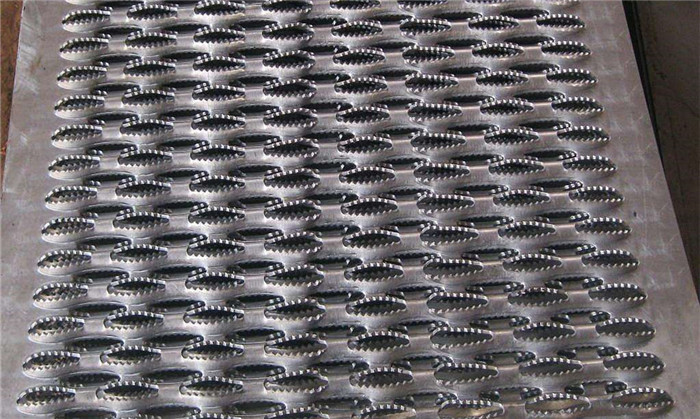

stainless steel Perforated sheet

Tooling Strength Is Another Crucial Factor

Tooling (dies and punches) plays a critical role in the quality and efficiency of perforated sheet production. When punching thick stainless steel sheets, the reverse force on the tooling increases significantly. If the tooling is not strong enough, it may crack, deform, or wear prematurely.

To avoid such issues, manufacturers often reduce the number of holes punched simultaneously when working with thicker sheets. In some cases, they use high-strength tool steels or reinforced dies, but this also affects the production cycle.

Moreover, the number of punch heads installed in the mold is limited by the material thickness. More punch heads mean more holes per operation but reduce the overall strength of the tooling setup. Conversely, fewer punch heads can handle thicker sheets but lower the productivity.

Conclusion: Choose the Right Thickness to Balance Efficiency

In conclusion, the thickness of stainless steel perforated sheets has a direct impact on production speed. Thicker sheets require greater punching pressure, place more stress on the equipment and tooling, and inevitably result in longer production cycles.

To achieve the best cost-performance ratio, customers should carefully select the appropriate sheet thickness based on their application needs. Balancing material strength, processing efficiency, and production costs is key to a successful project.

If you need assistance with material selection, custom perforation, or production planning, feel free to contact us. Our team is ready to offer you professional support and efficient solutions tailored to your requirements.