Punching Net Brief Introduction

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-11 18:41:09 Browse:

Punching net, also known as perforated sheet, perforated plate, or steel punching mesh, is a type of metal product created by using CNC punching machines to perforate metal sheets with holes arranged in specific patterns. This process results in a flat, smooth surface with excellent wear resistance and corrosion resistance, making Punching net a widely used solution in construction, industrial manufacturing, and modern design.

Punching Net Materials and Thickness

Punching net can be manufactured using a wide variety of metal sheet materials, including carbon steel, stainless steel, aluminum, galvanized steel, copper, and even engineered plastics. The choice of material depends on the intended application environment and performance requirements.

Common thickness options include 1.0mm, 2.0mm, and 3.0mm. However, customized thicknesses ranging from 0.3mm to over 10mm can be processed according to customer specifications, providing high flexibility for different projects.

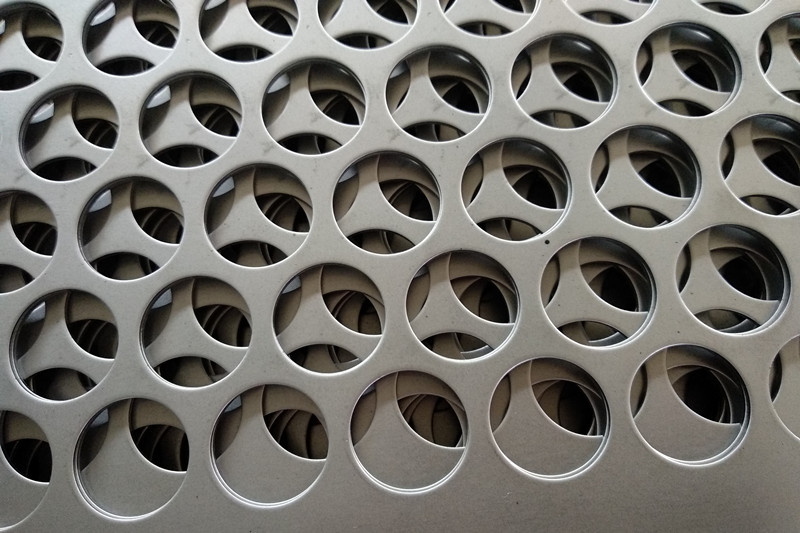

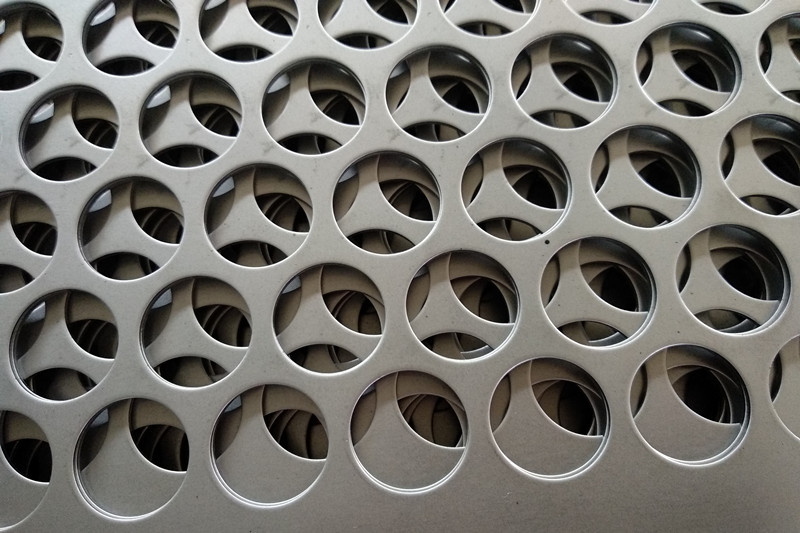

Punching net

Hole Types and Size Specifications

The hole diameter in Punching net can range from 1.0mm up to 200mm. Hole spacing and layout can be fully customized based on user needs or provided design drawings, offering a wide range of configurations.

Standard sheet dimensions include:

500×1000mm

600×1000mm

1000×2000mm

1220×2440mm

Custom sizes are also available upon request to suit specific project requirements.

Punching net

Surface Treatment Options

To enhance both durability and appearance, Punching net products can be treated with various surface finishing processes, such as:

Powder coating

Painting

Polishing

Anodizing (for aluminum sheets)

Galvanizing (for enhanced rust resistance)

These treatments improve aesthetics while significantly extending the lifespan of the product.

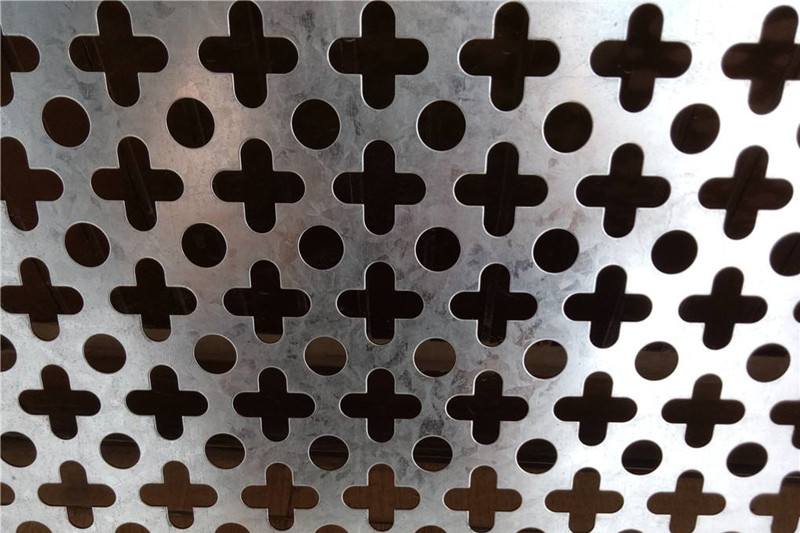

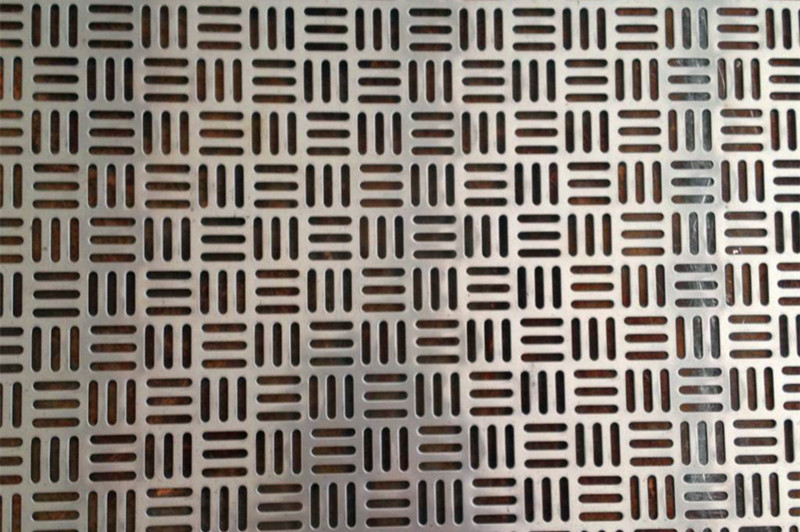

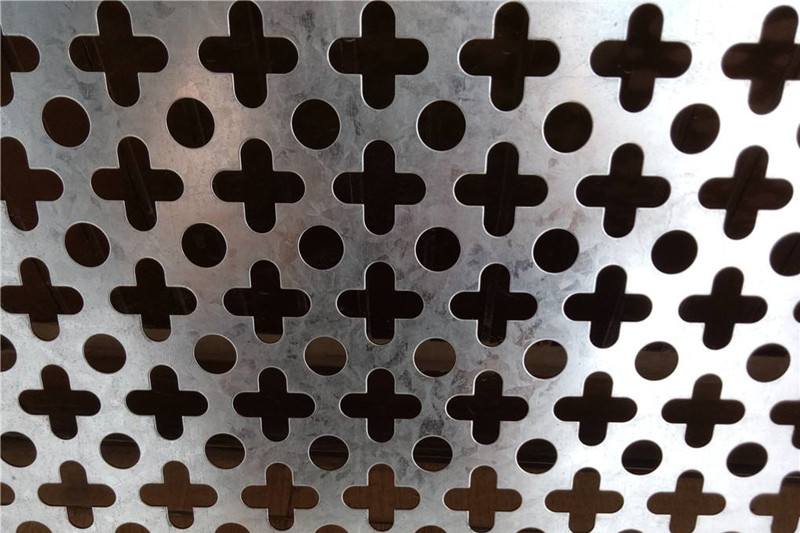

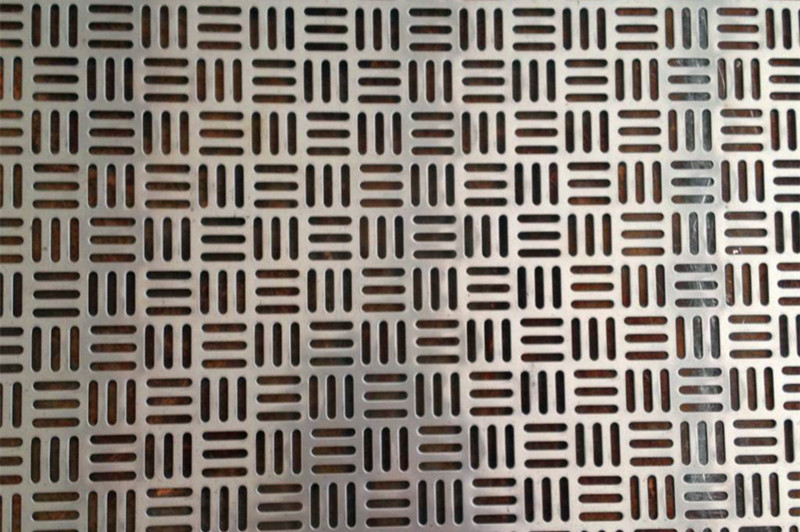

Available Hole Shapes

Punching net can be produced with a diverse array of hole types to match both functional and decorative needs. Common shapes include:

Round holes, elongated round holes

Square holes, diamond holes

Oval holes, fish-eye holes

Pentagonal and octagonal holes

Custom and decorative holes such as flower shapes, crocodile-mouth shapes, slotted holes, and combination patterns

Punching net

Classification of Punching Net

Punching net can be categorized based on material, hole shape, sheet thickness, processing method, and application:

By Material:

Copper punching net

Plastic perforated sheet

Mild steel punching net

By Hole Shape:

Crocodile-mouth punching net

Grid-shaped, hexagonal, fish-eye, pentagonal, and custom hole punching nets

By Thickness:

Thin sheet punching net (0.3mm–1.0mm)

Medium thickness (1.0mm–3.0mm)

Thick plate punching net (3.0mm–6.0mm)

Extra thick punching net (6.0mm and above)

By Processing Method:

CNC punching net

Laser cut perforated sheet

Micro-hole punching net

Anti-slip punching plate

By Application:

Decorative perforated panels

Protective covers for machines

Tread plates and anti-slip panels

Drainage plates and water filtration

Acoustic panels for sound absorption

Punching net

Applications of Punching Net

Due to its versatility, strength, and design flexibility, Punching net is used across a broad range of industries and environments:

Architectural decoration – For facades, ceilings, partitions, railings, and more

Machine safety protection – As protective covers for industrial equipment

Industrial screening and filtering – In mining, chemical processing, food processing, and agriculture

Ventilation and heat dissipation – Enhancing airflow in mechanical or storage environments

Speaker grills – For audio systems, ensuring both sound quality and protection

Traffic and infrastructure – Used in walkways, barriers, and fences

Kitchen appliances – As ventilation or separation components

Craft and design – In the creation of modern, functional artworks

Public projects – In drainage systems, safety fencing, and urban furniture

Agricultural systems – For grain ventilation, livestock safety, etc.

Conclusion

Punching net is more than just a metal sheet with holes—it's a highly adaptable solution combining function, durability, and aesthetic potential. Whether you're looking for efficient ventilation, protective enclosures, decorative elements, or industrial screening, we offer custom-made Punching net products tailored to your project requirements.

Feel free to contact us for expert support, technical specifications, and competitive pricing.