Aluminum Anti-skid Plate: Industrial Safety Flooring Solutions

China Manufacturing · Global Supply · Tailored Engineering

2025-01-10

2025-05-19

2025-06-07

2025-03-04

2025-05-19

2025-05-13

2025-06-14

2025-06-14

2025-05-21

2025-04-11

Walkway Grip Strut Safety Grating

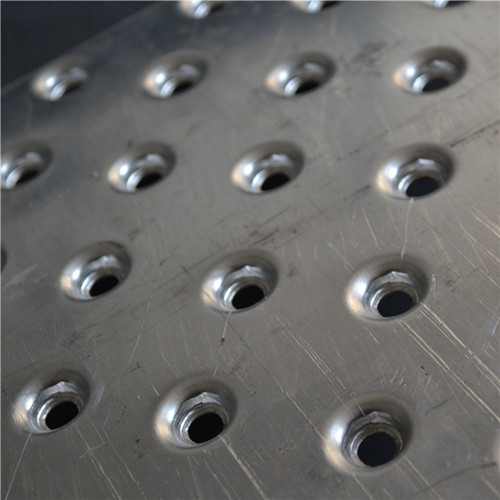

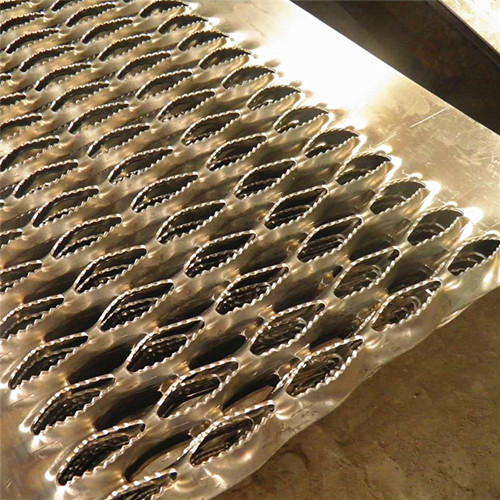

Convex Hole Grip Strut Safety Grating

Grain Sorting Screen Plate

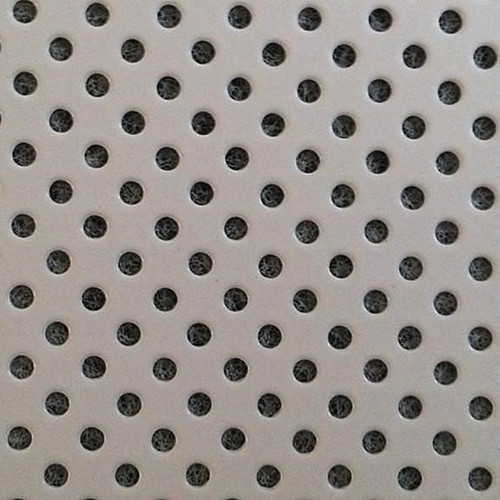

Micropore Sieve Sheet

Galvanized Screening Plate

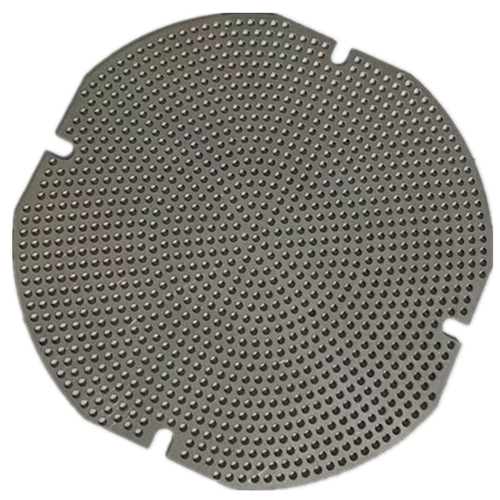

Convex Hole Anti-skid Plate

Slotted Hole Sieve Sheet

Stainless Steel Sieve Sheet

Anti-skid Stair tread plate

Galvanized Safety Grating

Carbon Steel Perforated Sheet

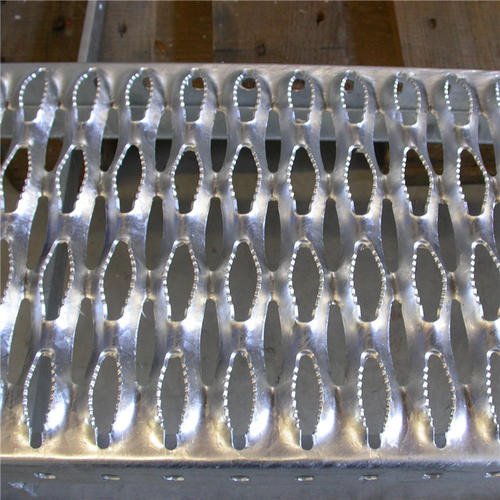

Fisheye Anti-Slip Grating

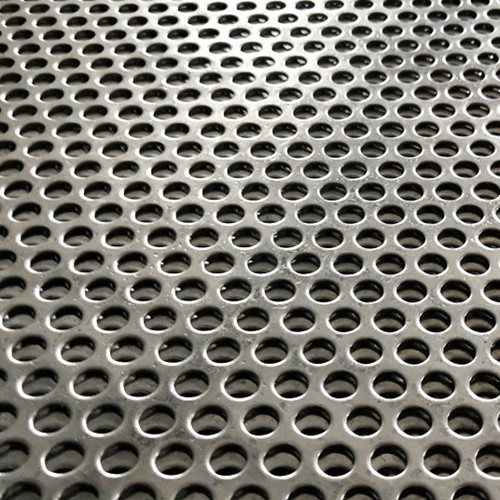

Circular Hole Sieve Sheet

Stair Grip Strut Safety Grating

Serrated Grip Strut Safety Grating