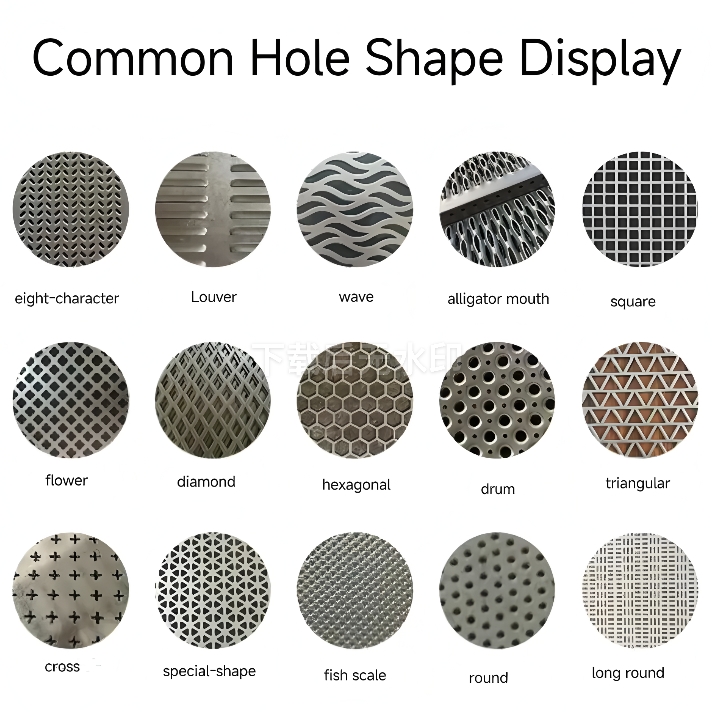

3. Can the Hole Pattern or Layout Be Customized?

Yes. The arrangement of holes significantly impacts the panel’s structural strength, visual design, and functional performance. We provide several layout options, as well as custom solutions:

Straight-line pattern (90° alignment): Clean and industrial, often used in machinery and enclosures.

Staggered pattern (45° or 60° offset): Enhances strength and increases open area, commonly used in architectural and acoustic projects.

Custom artistic patterns: Logos, gradients, or unique shapes designed for architectural branding or decorative purposes.

We accept custom designs based on drawings or samples, offering full flexibility in design and production.

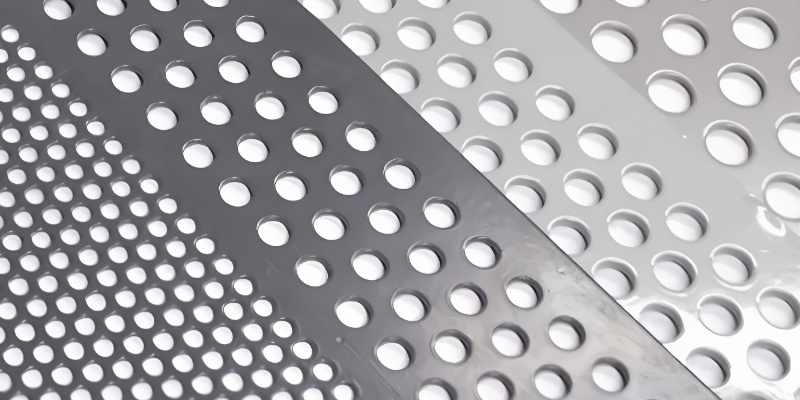

4. What Materials Are Available?

We supply metal perforated panels in a variety of materials to suit different environmental and performance needs:

Stainless steel: Corrosion-resistant and high-strength, ideal for medical, food-grade, or exterior architectural use.

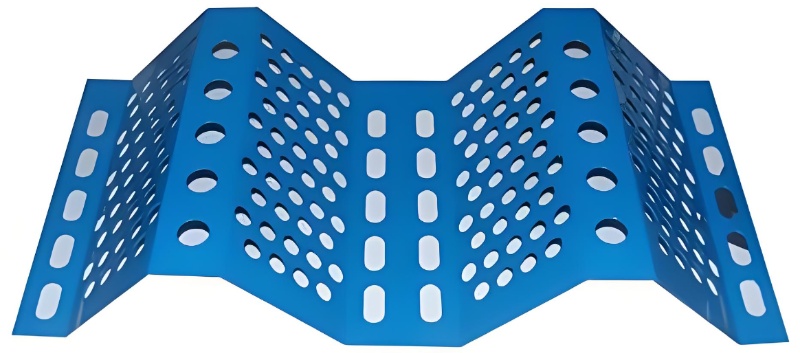

Aluminum: Lightweight and weather-resistant, suitable for ceilings, facades, and indoor applications.

Galvanized steel: Rust-resistant and economical, perfect for outdoor or industrial environments.

Copper and brass: Offer luxurious appearance and good conductivity, used in high-end interiors and electronics.