Product Overview

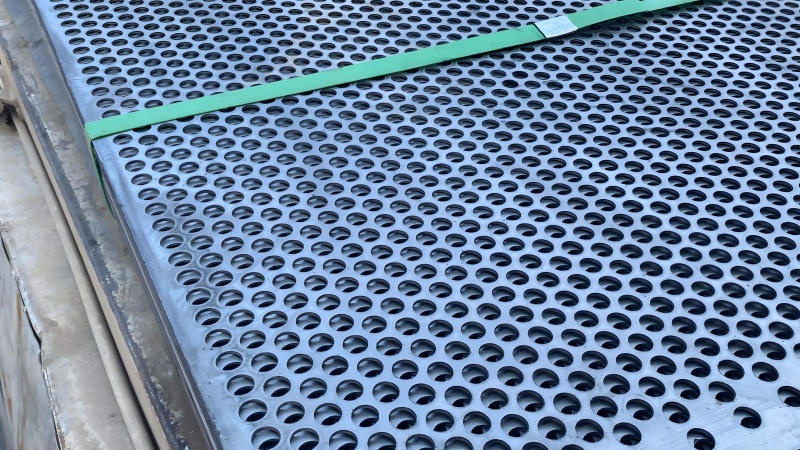

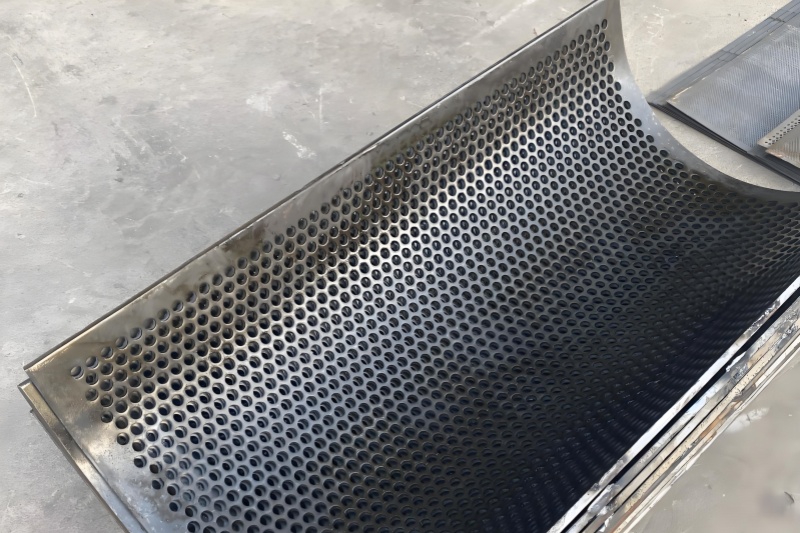

Grain sorting sieve plates are essential equipment in grain processing and cleaning industries, designed for precise separation of various cereals, seeds, and granular materials. As a specialized manufacturer based in China, we are committed to providing efficient, durable, and customizable grain sorting sieve plates that help global clients enhance production efficiency and optimize processing quality.

Our sieve plates undergo strict quality control measures to ensure each product meets technical specifications, delivering reliable screening performance for your production line. These products find extensive applications across agriculture, food processing, grain storage, and logistics sectors.

Key Product Features

Premium Materials

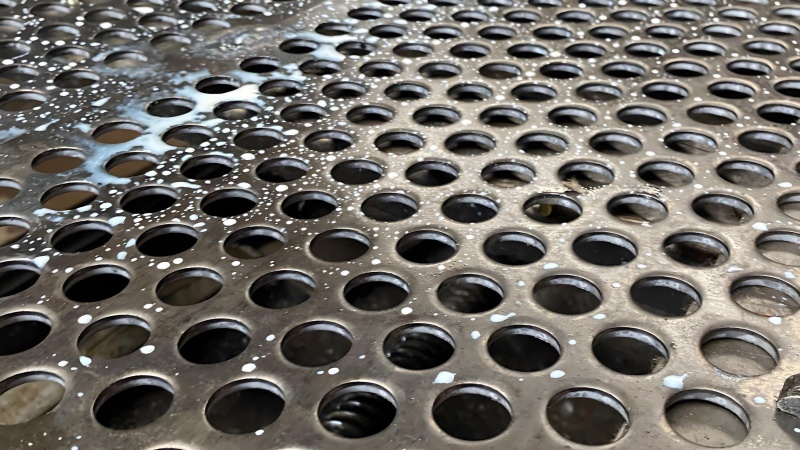

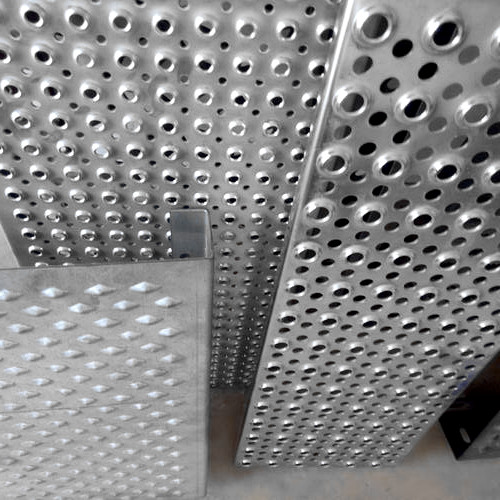

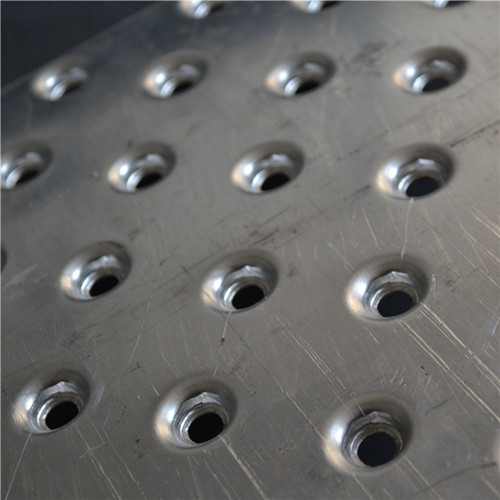

Manufactured from high-strength steel, aluminum alloy, and corrosion-resistant stainless steel, our sieve plates guarantee long-term durability. Specially treated materials withstand wear and corrosion, making them suitable for demanding and humid working conditions.

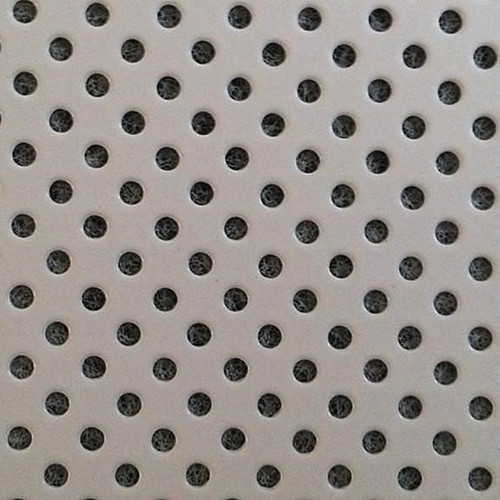

Precision Screening

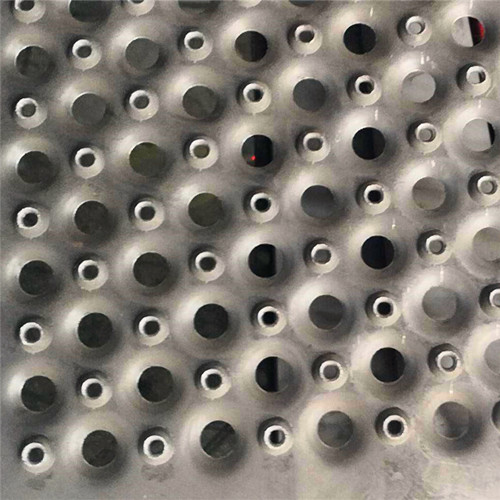

Accurately designed apertures and hole patterns ensure efficient material separation with maximum grading precision. Whether processing rice, wheat, corn or other grains, our sieve plates deliver optimal sorting results.

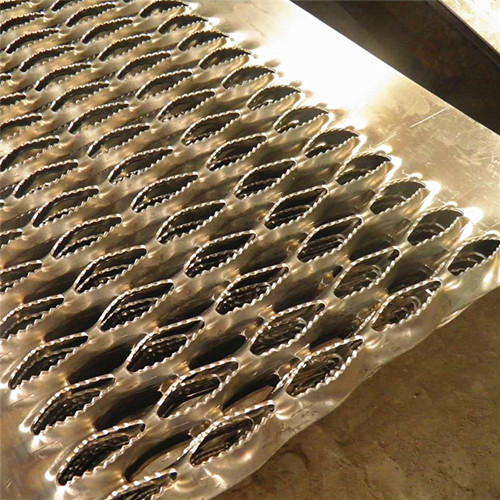

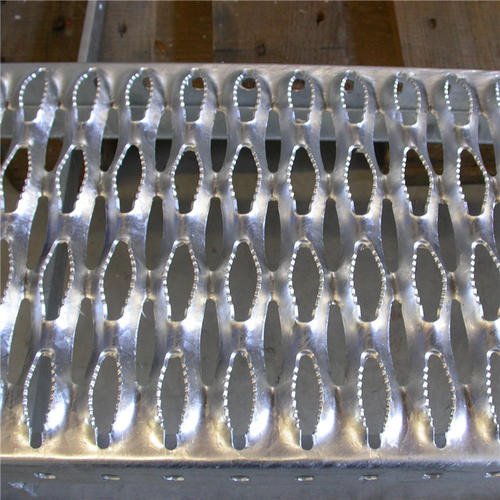

Anti-Slip Surface

Specially treated surfaces provide excellent anti-slip properties, preventing uneven material movement during operation. This feature ensures stable and efficient screening processes critical for maintaining production quality.

Exceptional Wear Resistance

Built for continuous heavy-duty operation, our sieve plates feature enhanced wear resistance through specialized surface treatments that extend service life even under extreme conditions.

Low Maintenance Design

Easy-to-clean surfaces and smooth edge treatments minimize grain residue accumulation and blockages, reducing downtime and operational costs.

Why Choose Us?

Industry Expertise

With extensive experience in sieve plate manufacturing, our technical team understands various grain characteristics and screening requirements. We provide professional consultation to recommend optimal solutions for your specific applications.

Global Reach

We maintain long-term partnerships with clients across Europe, North America, South America, and Asia, ensuring timely product delivery and technical support regardless of your location.

Continuous Innovation

Through advanced manufacturing techniques and ongoing design improvements, we develop sieve plates with superior efficiency, accuracy, and longevity to meet evolving industry demands.

Comprehensive Support

From product selection to installation guidance, our dedicated team provides complete after-sales service to address any operational challenges promptly.

Contact Us

Interested in our grain sorting sieve plates or need more information? Reach out through:

Email: 342096438@qq.com

Our specialists will provide personalized product recommendations and quotations tailored to your requirements. Whether you need standard products or customized solutions, we're ready to support your operations.

As a professional sieve plate manufacturer, we recognize the unique screening needs of different regions and crops. Through global collaborations, we've developed practical solutions to enhance your grain processing efficiency and quality. We look forward to building lasting partnerships that drive mutual success.

2025-06-07

2025-04-11

2025-01-10

2025-05-19

2025-06-14

2025-05-19

2025-05-21

2025-06-14

2025-05-13

2025-03-04

Perforated Grip Strut Safety Grating

Grain Sorting Screen Plate

Slotted Hole Sieve Sheet

Heavy Duty Perforated Screens

Perforated Anti-skid Plate

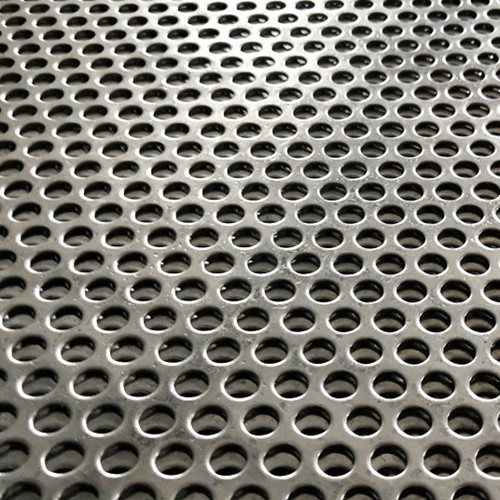

Circular Hole Sieve Sheet

Carbon Steel Grip Strut Safety Grating

Convex Hole Grip Strut Safety Grating

Serrated Grip Strut Safety Grating

Galvanized Screening Plate

Carbon Steel Perforated Sheet

Stainless Steel Grip Strut Safety Grating

Walkway Grip Strut Safety Grating

Stainless Steel Sieve Sheet

Galvanized Safety Grating