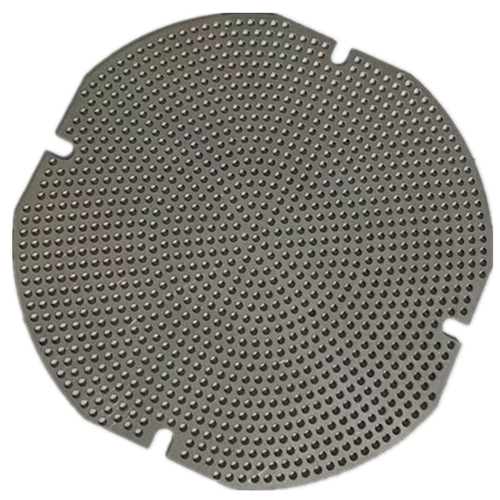

Micropore Sieve sheet Production video

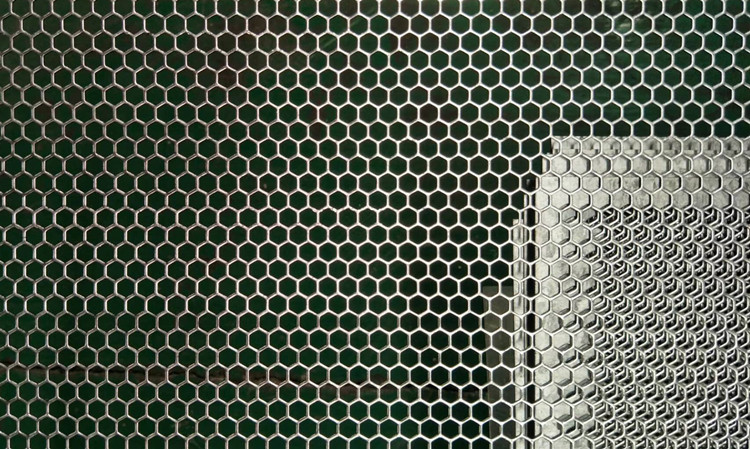

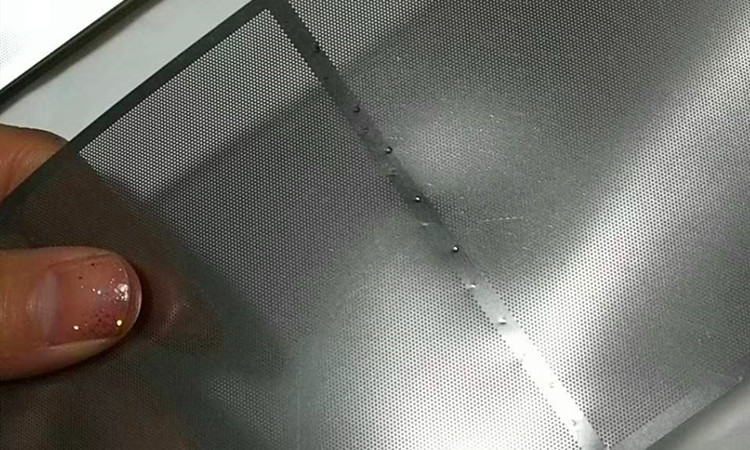

Micropore Sieve Sheets are precision-filtering screens made from high-quality metal plates using CNC punching technology. As a specialized Chinese manufacturer, we provide standardized and custom-designed solutions for global clients. Our products are widely used in chemical industry , pharmaceuticals, food processing, machinery manufacturing, and environmental engineering for screening, filtering, and separation processes.

Q: How to select the right aperture size?

A: Choose 1.2–1.5× the maximum particle size of your material.

Q: Corrosion resistance comparison?

A: Stainless steel > aluminum > galvanized steel > cold-rolled steel (select based on environment).

Q: Product lifespan?

A: 3–5 years for stainless steel under normal conditions (varies with usage intensity).

2025-06-14

2025-01-10

2025-05-21

2025-03-04

2025-05-13

2025-06-07

2025-05-19

2025-06-14

2025-04-11

2025-05-19

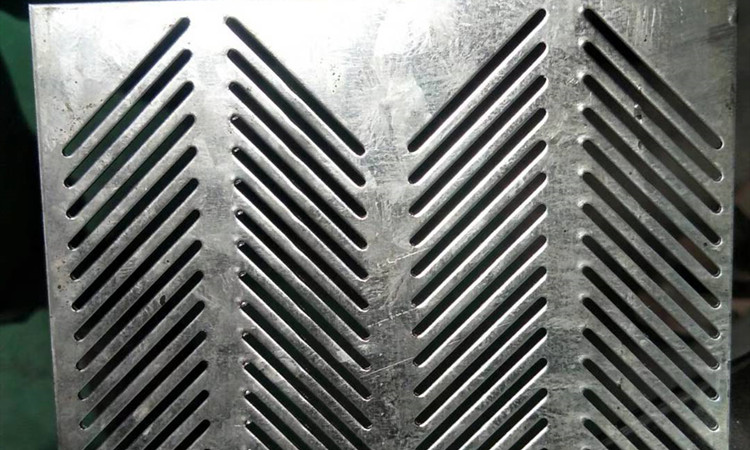

Walkway Grip Strut Safety Grating

Stair Grip Strut Safety Grating

Perforated Grip Strut Safety Grating

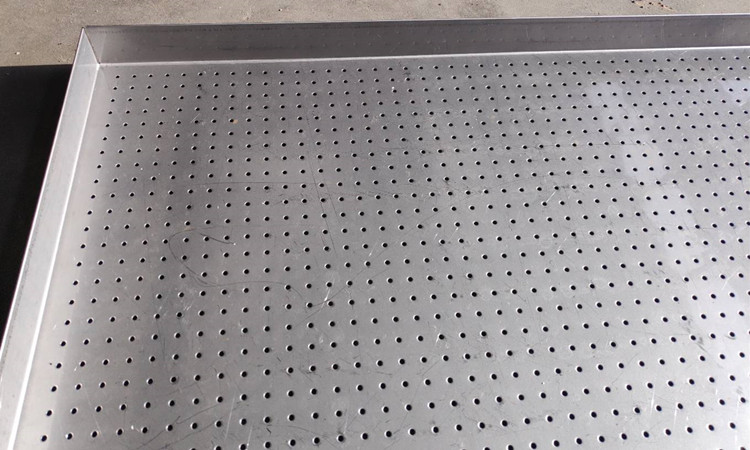

Carbon Steel Perforated Sheet

Heavy Duty Perforated Screens

Carbon Steel Grip Strut Safety Grating

Aluminum Anti-skid Plate

Grain Sorting Screen Plate

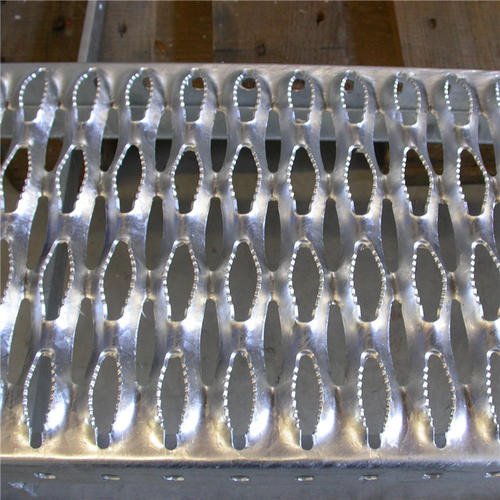

Fisheye Anti-Slip Grating

Metal Safety Grating

Galvanized Safety Grating

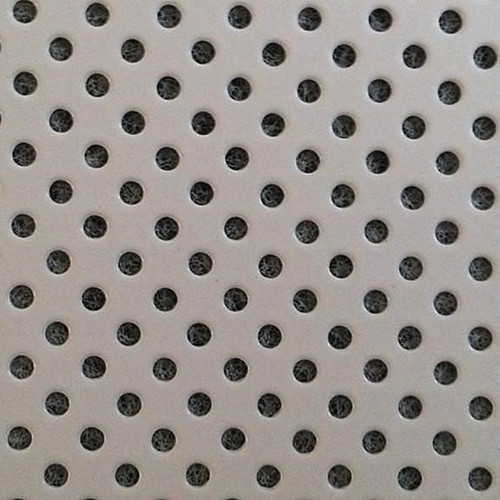

Circular Hole Sieve Sheet

Carbon Steel Punched Metal Plate

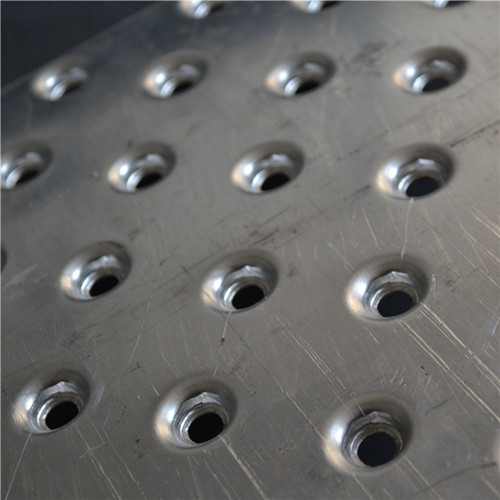

Convex Hole Grip Strut Safety Grating

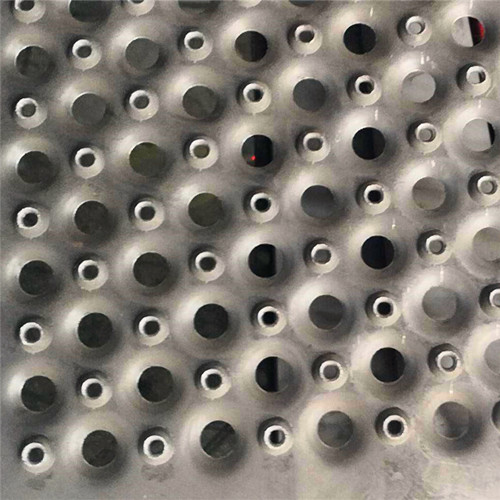

Micropore Sieve Sheet