What Are the Materials for Stainless Steel Perforated Sheets? A Complete Guide

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 16:17:24 Browse:

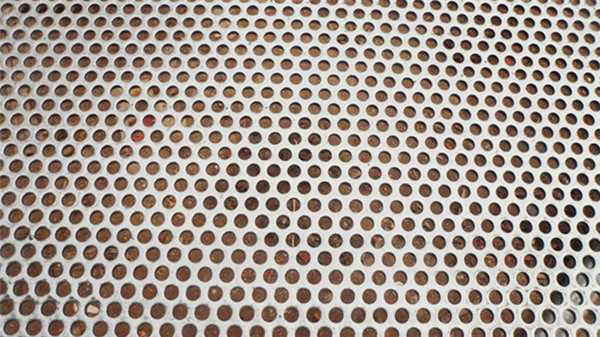

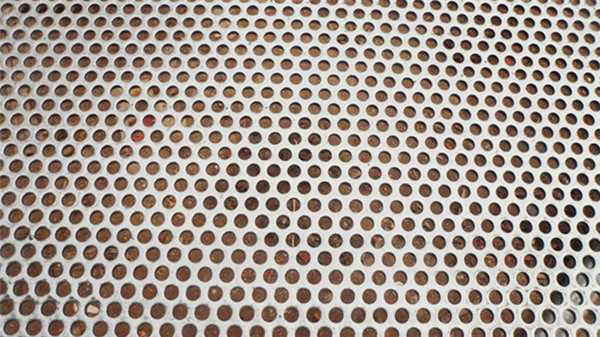

Stainless steel perforated sheet is a versatile metal product widely used in industries such as construction, decoration, filtration, and machinery protection. It is manufactured by precisely punching high-quality stainless steel sheets through CNC-controlled presses based on custom-made molds, creating a net-like appearance with excellent mechanical properties and aesthetic appeal.

One of the key advantages of stainless steel perforated sheets lies in the wide range of raw materials available. Depending on different environmental and functional requirements, various stainless steel grades can be selected. So, what materials are commonly used in stainless steel perforated sheets? What are their characteristics? Let’s explore in detail.

1. Common Material Types for Stainless Steel Perforated Sheets

The diversity of raw materials is a significant advantage of stainless steel perforated sheets. Nearly all stainless steel sheet types on the market can be processed into perforated panels. Below are the most commonly used materials:

1.1 201 Stainless Steel

201 stainless steel is a manganese-based alloy known for its affordability. It has decent oxidation resistance and good mechanical strength, making it suitable for indoor or dry environments. However, it is not recommended for humid or corrosive conditions as it may rust over time.

1.2 304 Stainless Steel

304 stainless steel is the most commonly used austenitic stainless steel. It offers excellent corrosion resistance and workability, making it ideal for most perforated sheet applications—such as architectural cladding, food processing equipment, safety covers, and more. It strikes a great balance between cost and performance.

1.3 316 Stainless Steel

316 stainless steel includes molybdenum, giving it superior corrosion resistance—especially in salty or acidic environments. It is widely used in marine applications, chemical plants, and medical equipment. When higher resistance to pitting corrosion is needed, 316 is a top choice.

1.4 316L Stainless Steel

316L is the low-carbon version of 316, offering improved weldability and better resistance in aggressive chemical conditions. It’s often used in welding-intensive applications such as chemical pipelines, shipbuilding, and high-end fabrication.

1.5 409 Stainless Steel

409 stainless steel belongs to the ferritic family, with enhanced heat resistance and oxidation resistance. It is commonly used in automotive exhaust systems and other high-temperature environments. Its cost-effectiveness makes it a preferred option for certain industrial uses.

1.6 430 Stainless Steel

430 is another ferritic stainless steel, valued for its good formability and corrosion resistance. It is often found in decorative applications, home appliances like refrigerator panels, and elevator interiors.

1.7 439 Stainless Steel

439 stainless steel improves upon 430 by offering better weldability and corrosion resistance. It is suitable for automotive manufacturing, heat exchangers, kitchen equipment, and other applications where forming and welding are required.

Stainless steel perforated sheet

2. Custom Material Options Available

In addition to the above standard grades, stainless steel perforated sheets can be made from other materials based on customer requirements. As long as the stainless steel sheet exists on the market, it can typically be processed through perforation. Special alloy steels or composite stainless steel sheets can also be custom ordered for unique applications.

3. Overview of the Manufacturing Process

The primary manufacturing method for stainless steel perforated sheets is precision punching. Using advanced CNC punching machines and customized tooling, holes of various shapes—such as round, square, slotted, or hexagonal—are punched into the sheet in a consistent and high-speed process. This ensures accurate hole placement while preserving the flatness and structural strength of the sheet.

4. How to Choose the Right Stainless Steel Material

When selecting a stainless steel perforated sheet, it is crucial to consider the usage environment, budget, and maintenance expectations. Here are some general suggestions:

For budget-sensitive, indoor use: Choose 201 or 430 stainless steel.

For general-purpose applications: 304 stainless steel is a well-balanced option.

For corrosive or marine environments: Opt for 316 or 316L for best durability.

For high-temperature or automotive parts: 409 or 439 stainless steel is recommended.

Conclusion

Stainless steel perforated sheets combine functionality with visual appeal, making them a popular choice for building facades, acoustic panels, safety guards, filtration systems, and more. Selecting the right material ensures long-lasting performance and reduces maintenance costs.

Understanding the characteristics of each stainless steel grade is essential to make informed decisions. If you have any questions about selecting or customizing stainless steel perforated sheets, feel free to contact us—we're here to help with professional guidance and premium products.