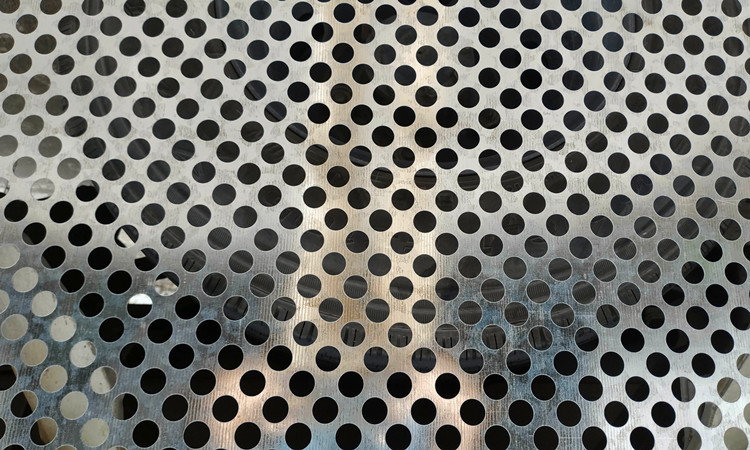

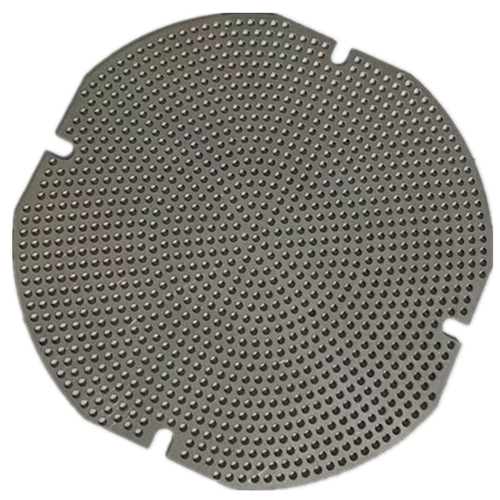

Perforated metal panels, also known as perforated plates, are mesh products made from high-quality metal sheets through CNC punching machines using continuous blanking technology. As a professional factory specializing in the custom manufacturing of perforated metal panels, we are dedicated to providing tailored solutions based on the specific needs of our customers. Whether it’s hole types, hole spacing, sheet thickness, or special material choices, we can precisely manufacture according to customer requirements to meet the demands of various application scenarios.

Our Advantages

Professional Customization Services: We specialize in custom manufacturing perforated metal panels, offering flexibility to tailor hole types, hole diameters, hole spacing, sheet thickness, and material types. Whether you need standard sizes or have special requirements, we provide the perfect solution.

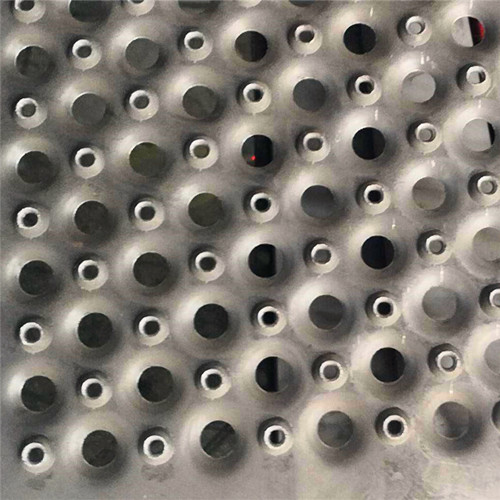

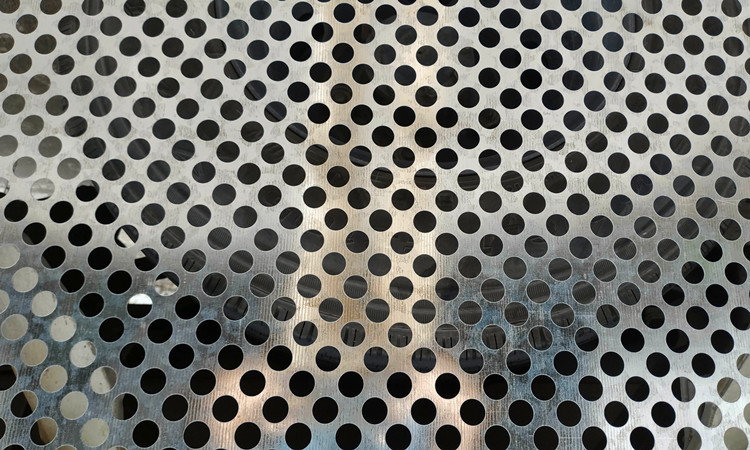

Precision Manufacturing Technology: Using advanced CNC punching machines, we ensure uniform hole spacing and precise hole shapes. Our production processes are rigorously controlled to ensure each perforated metal panel meets international standards and satisfies customer quality requirements.

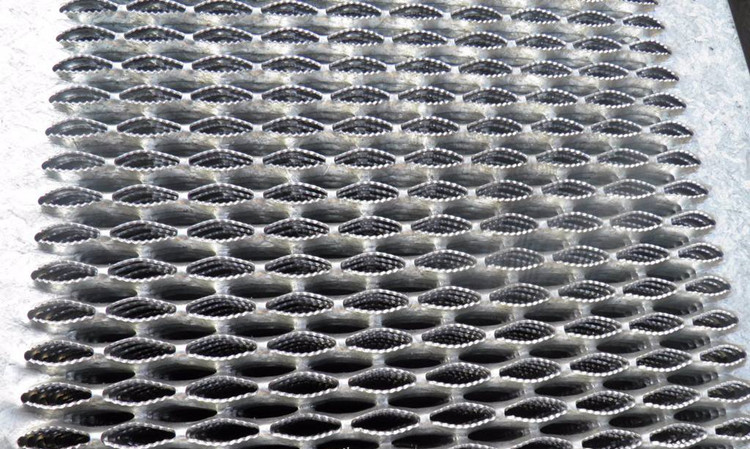

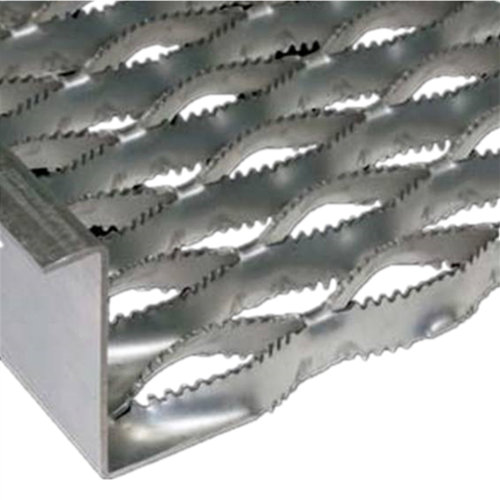

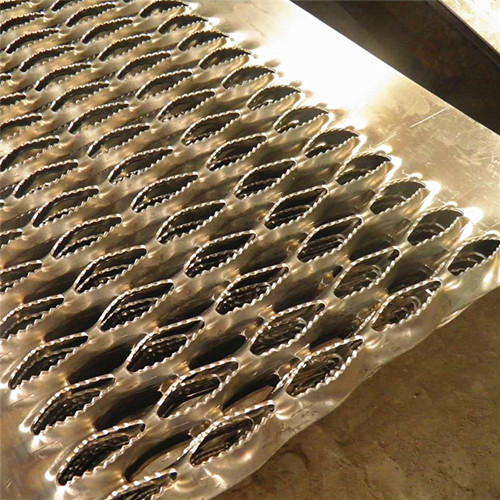

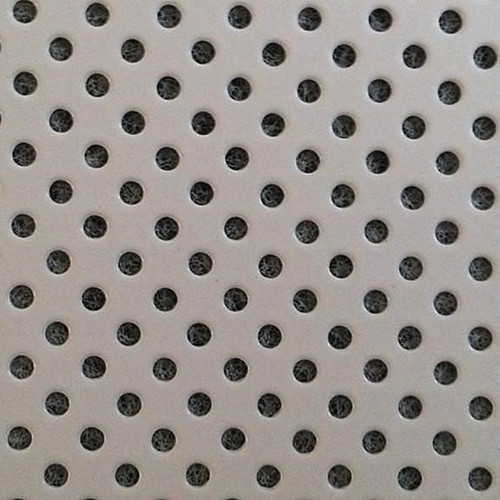

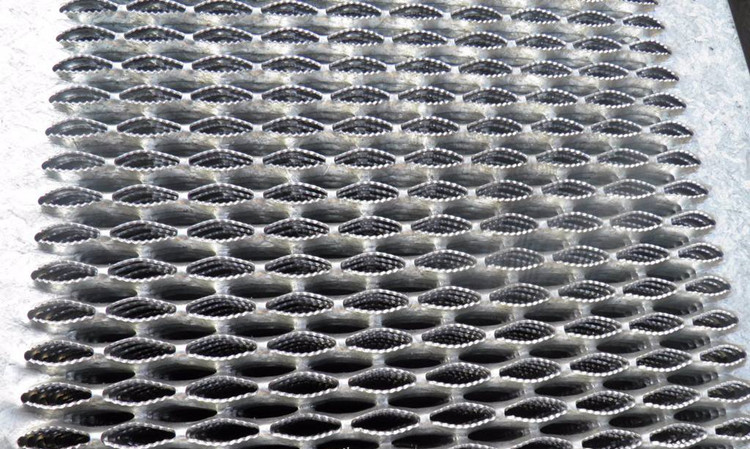

Diverse Hole Types and Layout Options: We offer a wide range of common hole types, including round holes, oval holes, square holes, rectangular holes, fish scale holes, diamond holes, zigzag holes, and more. We also provide various hole arrangements, such as 60° staggered, 45° staggered, and 90° aligned, with custom layout options available upon request.

Flexible Material Choices: We offer a variety of metal materials for customers to choose from, including iron, aluminum, and stainless steel plates. Common iron plate materials include Q235 low carbon steel, Q345 manganese steel, etc. Aluminum plates include 1050, 1060, 3003, etc., while stainless steel plates come in 304, 316, 316L, and other types.

Comprehensive Post-Processing and Fabrication Services: In addition to standard perforating, we also offer cutting, bending, laser cutting, surface coating, polishing, and other deep processing services. Whether it’s precise dimensional requirements or special surface treatments, we provide one-stop solutions.

Strict Quality Control: Our production process is governed by a strict quality control system to ensure that each batch of perforated metal panels meets industry standards. Every product undergoes multiple checks, including hole spacing, hole diameter, and sheet thickness, to ensure the highest quality.

Fast Turnaround and High Efficiency: With highly automated production equipment and processes, we can quickly respond to customer needs, significantly reducing delivery time and meeting urgent project requirements.

Application Fields

Our perforated metal panels are widely used across various industries, including construction, industrial, environmental protection, electronics, and machinery. Notable applications include:

Building Decoration: Perforated metal panels are commonly used in modern architecture for ceiling panels, wall coverings, and railings, offering both aesthetic appeal and acoustic properties, improving indoor comfort.

Mechanical Equipment Protection: These panels are used as protective covers for mechanical equipment, speaker grilles, and other applications, combining safety with visual appeal.

Acoustic Soundproofing and Ventilation Systems: Our fish scale perforated panels are especially suitable for soundproofing and ventilation systems, used extensively in noise control, air conditioning, HVAC, and other systems to optimize airflow and sound wave propagation.

Electronic Product Dust Covers: In the electronics industry, perforated metal panels are used as dust covers or sound insulation covers for audio equipment, protecting electronic components from external contaminants while maintaining excellent sound quality.

Environmental Protection and Filtration: Perforated metal panels are widely used in environmental protection and filtration equipment, providing efficient filtration and ventilation performance.

Other Custom Needs: In addition to common applications, we also provide customized solutions for various industries, such as warehouse ventilation, food industry fruit trays, industrial equipment safety nets, and more.

Product Specifications

Our perforated metal panels offer high flexibility in customization. Specifications and sizes can be tailored based on customer requirements:

Sheet Thickness: Customizable from 0.1mm to 20mm, meeting various application needs.

Material Choices: Customers can choose from iron plates, aluminum plates, stainless steel plates, etc. Common materials include Q235 low carbon steel, Q345 manganese steel, 1050, 1060 aluminum plates, 304, 316 stainless steel plates, etc.

Sheet Size: We can customize perforated metal panels in different sizes. Standard sizes include 1000mm×2000mm, 1250mm×2500mm, 1500mm×3000mm, and more. Custom sizes are also available upon request.

Hole Diameter and Hole Spacing: Hole diameters can be customized from 0.2mm to 300mm. Hole spacing is also customizable to meet specific needs, with a general rule that hole edge-to-edge spacing should not be smaller than the sheet thickness.

Hole Types: We offer a wide range of hole types, including round holes, square holes, oval holes, fish scale holes, diamond holes, zigzag holes, and more. Special-shaped holes can also be customized based on user requirements.

Layout Options: Standard layouts include 60° staggered, 45° staggered, 90° aligned, with special layouts available upon request.

Price Introduction

The price of perforated metal panels varies based on specifications and models. Please contact us via email to provide your specifications and requirements, and we will provide an accurate quote.

Contact Us

If you are interested in our perforated metal panels or would like to learn more about our customization options, please feel free to contact us via email: 342096438@qq.com