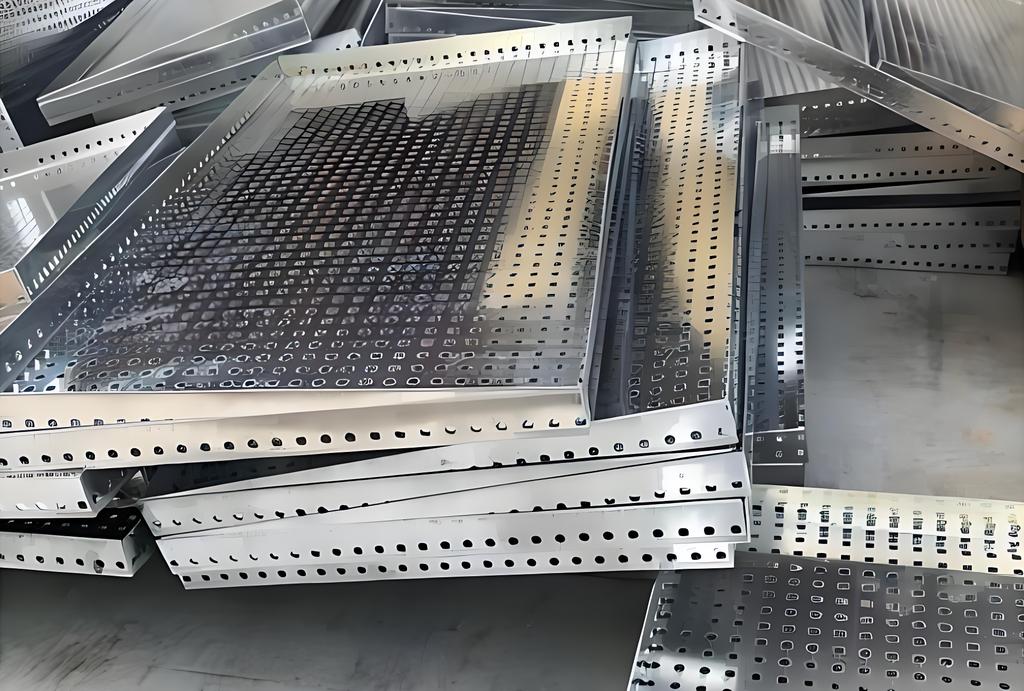

In the modern food processing and baking industry, the Perforated Tray for Baking has become an indispensable tool. With its excellent breathability and even heat conduction, the Perforated Tray for Baking not only enhances the quality of baked goods but also significantly boosts production efficiency. As a professional manufacturer of the Perforated Tray for Baking, we are dedicated to providing high-quality, customizable baking solutions that far surpass the standard products offered by ordinary distributors.

Why Choose Our Perforated Tray for Baking?

Professional Customization to Meet Diverse Needs

Standard specifications on the market often fail to fully meet the production requirements of different customers. We offer one-on-one customization services, tailoring the Perforated Tray for Baking to your baking equipment specifications, food types, and production process needs to create the perfect solution for you.

2025-05-13

2025-06-14

2025-04-11

2025-06-14

2025-05-19

2025-06-07

2025-03-04

2025-01-10

2025-05-21

2025-05-19

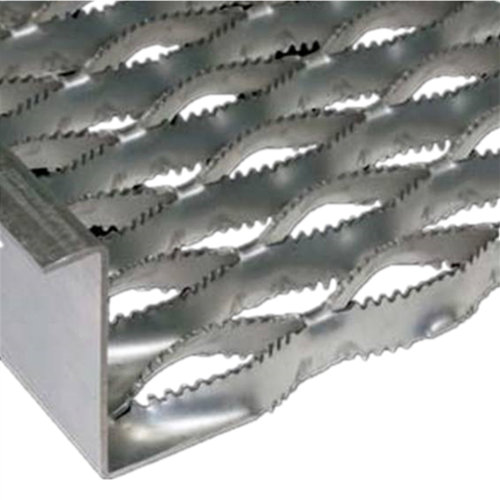

Stair Grip Strut Safety Grating

Galvanized Safety Grating

Walkway Grip Strut Safety Grating

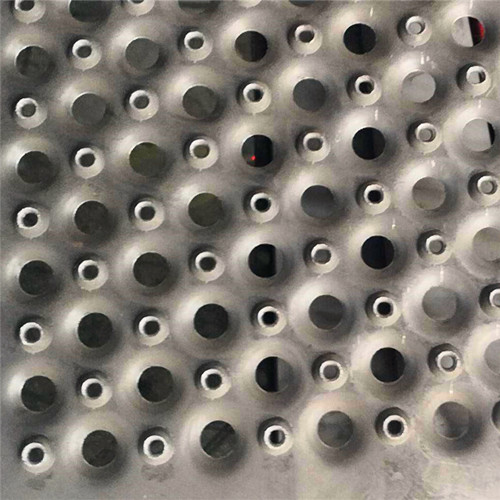

Heavy Duty Perforated Screens

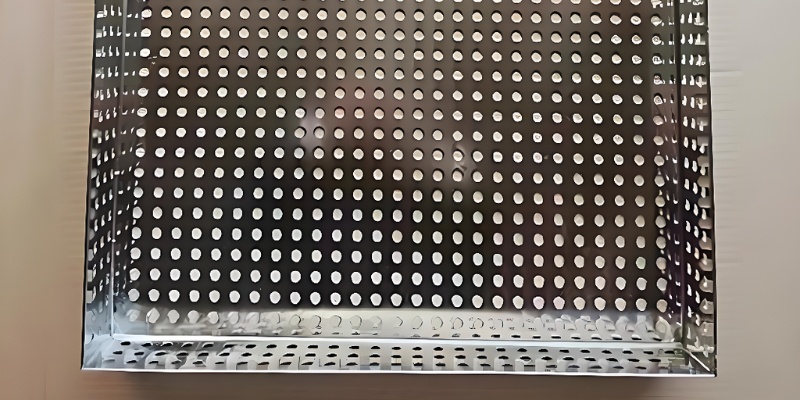

Perforated Sieve Sheet

Concentric circular sieve plate

Aluminium Grip Strut Safety Grating

Carbon Steel Grip Strut Safety Grating

Perforated Grip Strut Safety Grating

Stainless Steel Grip Strut Safety Grating

Grip Strut Safety Grating

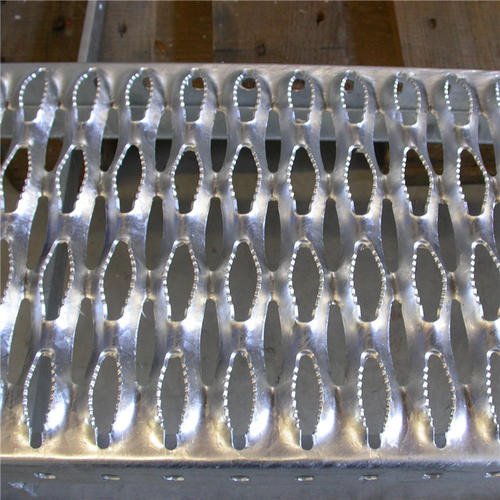

Convex Hole Grip Strut Safety Grating

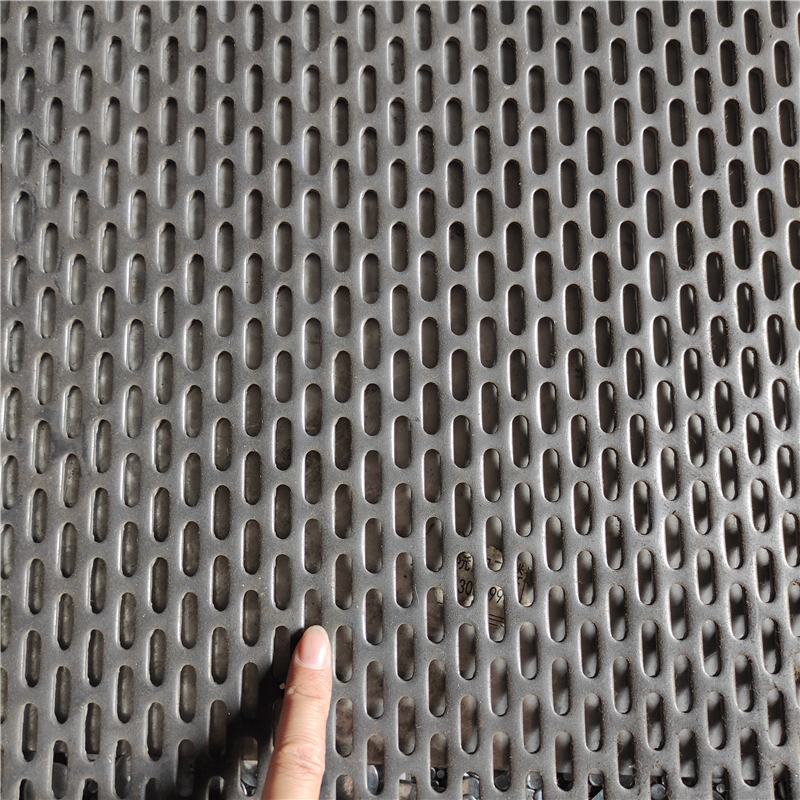

Galvanized Screening Plate

Steel Grip Strut Safety Grating

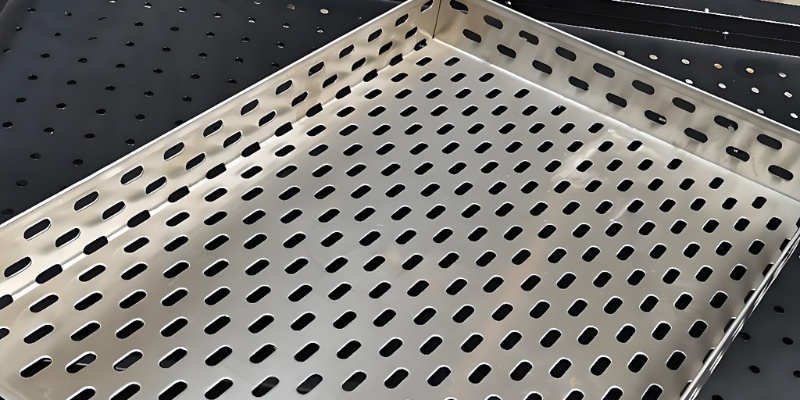

Obround Hole Sieve Sheet