Product Overview

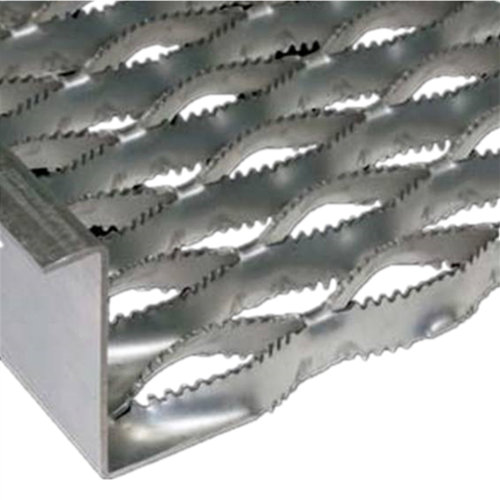

Steel Grip Strut Safety Grating is a premium anti-slip steel grating manufactured using CNC punching technology with custom molds. As a specialized factory in China, we supply standardized and tailor-made solutions globally for power plants, water treatment facilities, municipal engineering, transportation infrastructure, and aquaculture operations. Our unique hole patterns and material selections significantly enhance workplace safety by minimizing slip-and-fall risks.

Core Advantages

Superior Anti-Slip Performance

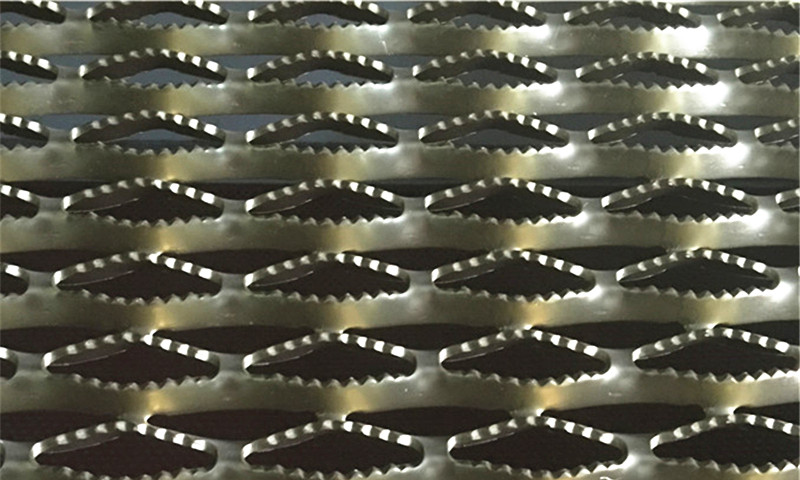

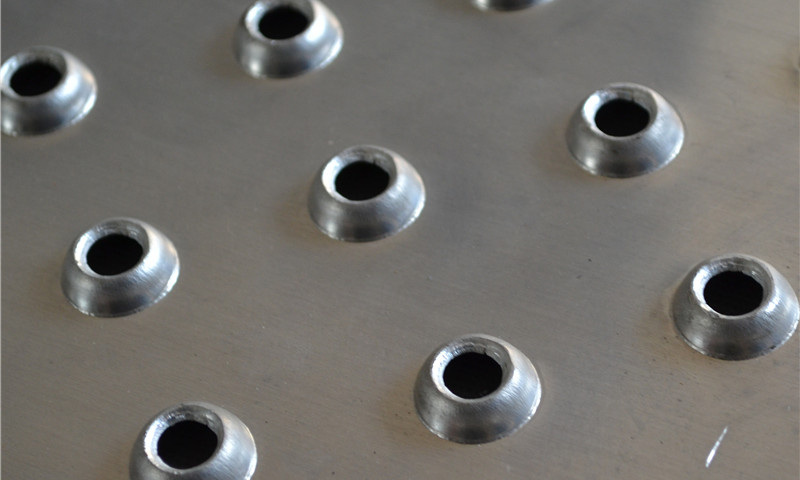

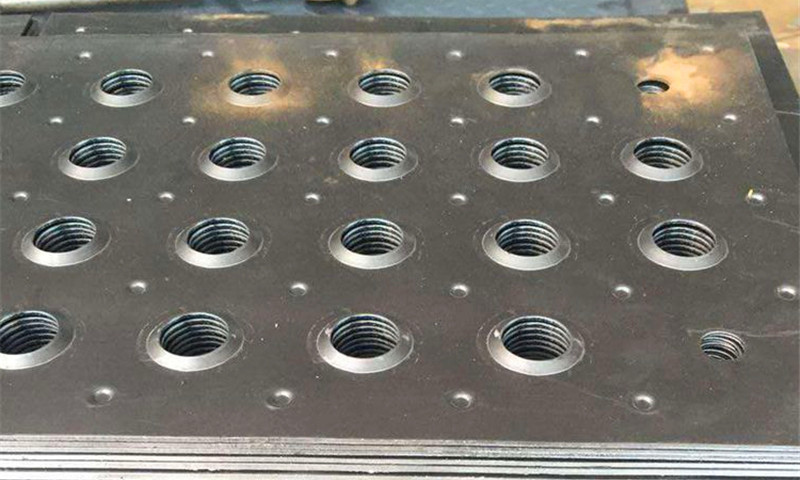

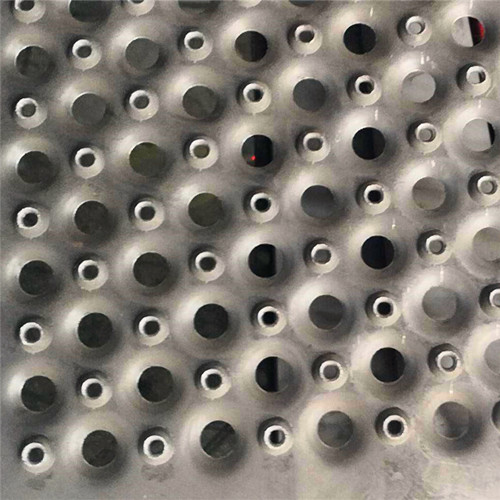

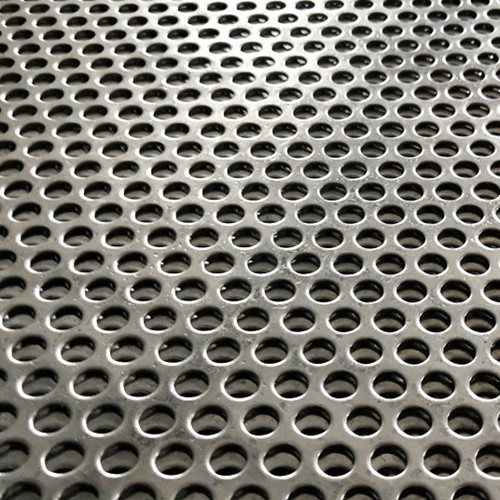

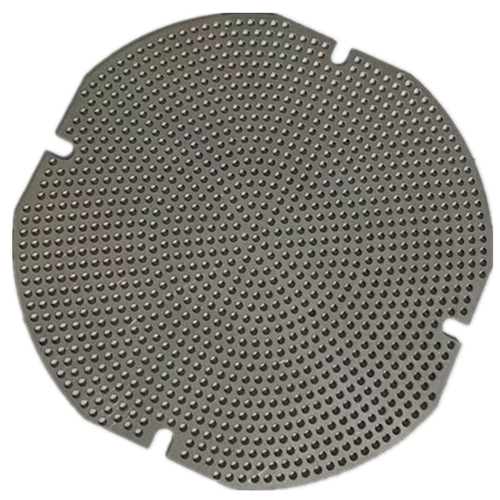

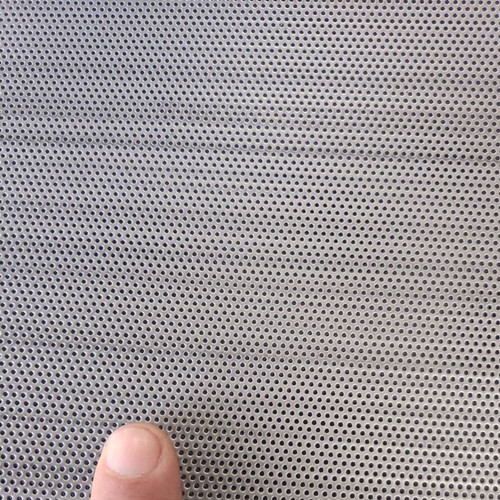

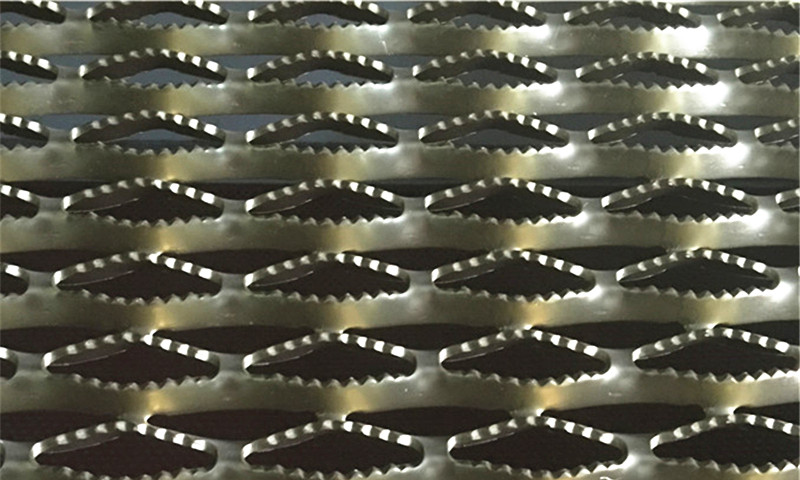

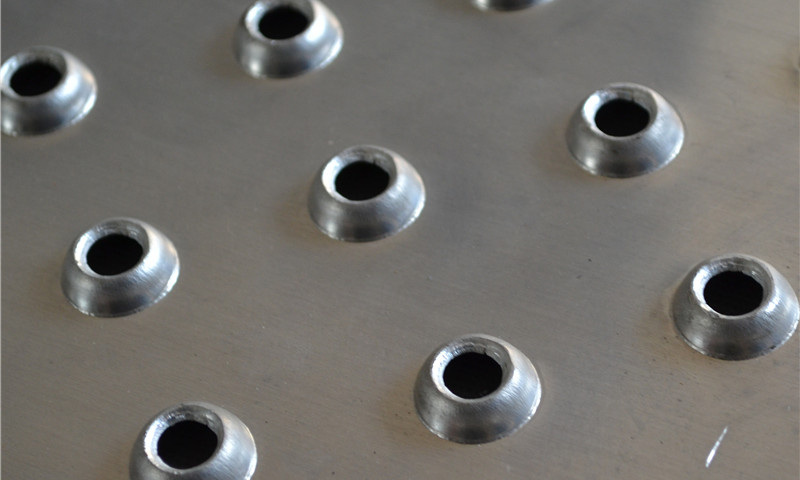

3D textured surfaces from Crocodile Mouth, Fisheye, or Flanged hole designs maximize friction coefficients – ideal for wet, oily, or hazardous environments.

Heavy-Duty Durability

Constructed from high-quality low-carbon steel (cold-rolled/hot-rolled/galvanized options), our Steel Grip Strut Grating undergoes precision punching for exceptional load-bearing capacity and deformation resistance in industrial settings.

Custom Corrosion Protection

Choose galvanization or specialized surface treatments tailored to your environment’s corrosion level (chemical plants, coastal areas, etc.) to extend product lifespan.

Engineered Functionality

Optimized open-area ratios and hole patterns balance drainage/ventilation needs with safety compliance, meeting international project specifications.

Technical Specifications

Materials: Cold-rolled steel, hot-rolled steel, galvanized steel, custom alloys

Thickness: 1.0mm – 4.0mm (non-standard options available)

Standard Sizes: Width ≤1.5m, Length ≤4m (oversize panels via segmented design)

Hole Patterns: Crocodile Mouth, Fisheye, Flanged (custom designs supported)

Load Capacity: Engineered solutions based on thickness & hole configuration

Global Applications

Energy Sector: Power plant maintenance platforms, substation walkways

Environmental: Wastewater treatment plant catwalks, filtration access areas

Transportation: Bridge footpaths, railway platform edges, port dock grating

Industrial: Factory stair treads, machinery guard platforms, aquaculture walkways

Food Processing: Slippery workstation flooring, processing line access

Customization Services

As experts in perforated metal manufacturing, we deliver deep customization:

Non-Standard Sizing: Oversized width/length via segmented fabrication

Proprietary Hole Designs: Custom patterns for specific drainage/anti-slip needs

Material Solutions: Special alloys for high-salt, high-temperature, or chemical exposure

Volume Order Efficiency: Cost-optimized production for bulk projects

Why Partner With Our China Factory

Precision Manufacturing: ±0.1mm hole accuracy via CNC punching systems

Scalable Production: Prototyping to high-volume orders (10,000+ tons)

Compliance Focus: Products meet industrial safety standards

Global Expertise: Exports adapted to diverse climates and installation codes

Request Your Solution

Email project details for a tailored quote:

342096438@qq.com

For fastest response, include:

① Application environment

② Dimensions (W×L×T)

③ Material/thickness preferences

④ Special needs (corrosion resistance/load capacity/etc.)

⑤ Estimated quantity