Key Advantages

1.Diverse Material Options

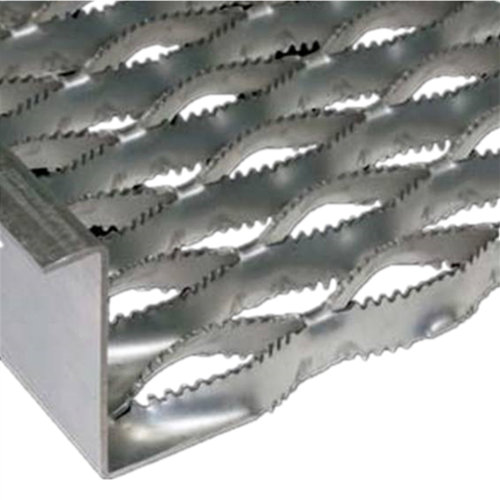

Cold-rolled steel (smooth finish), hot-rolled steel (high load-bearing), galvanized steel (weather-resistant), and manganese steel (abrasion-resistant for heavy industry).

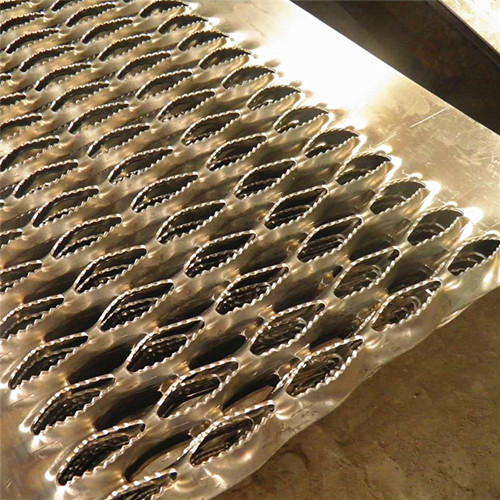

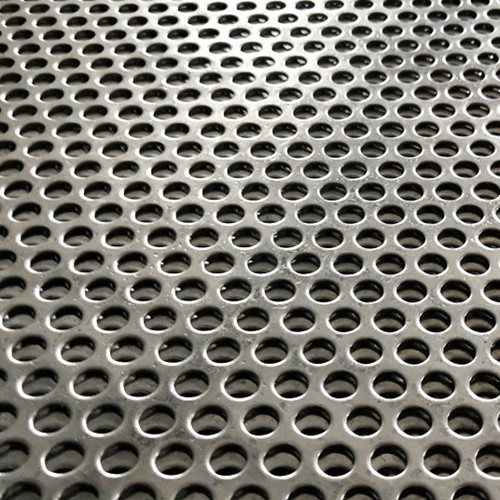

2.Precision Manufacturing

CNC-controlled punching ensures uniform hole distribution and flawless flatness.

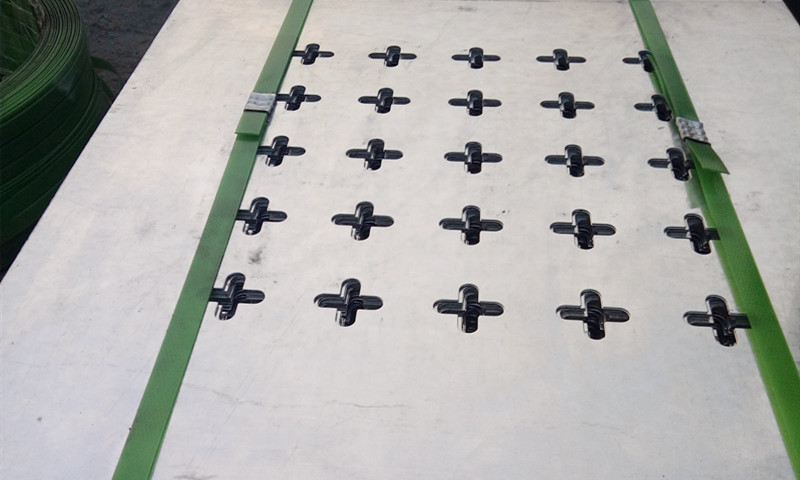

3.Tailored Customization

Adjust thickness (0.1mm–20mm), dimensions, hole patterns (cross-shaped), and spacing to meet project-specific needs.

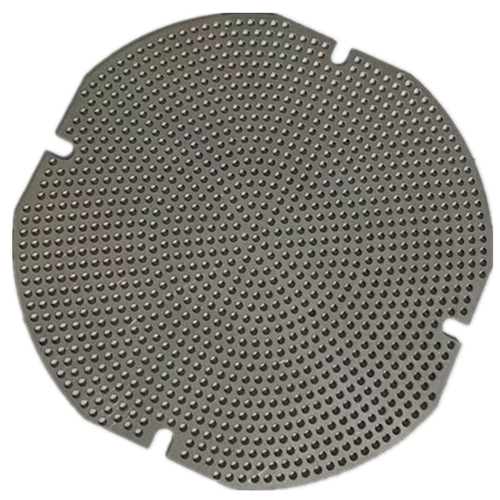

4.Multifunctional Design

Balances aesthetics, ventilation, safety barriers, noise reduction, and filtration.

Technical Specifications

Thickness Range: 0.1mm–20mm (thin for decor; thick for industrial strength).

Standard Sizes: 1000×2000mm, 1250×2500mm, 1500×3000mm (non-standard sizes supported).

Hole Design: Customizable aperture, pitch, and density for optimal light/airflow vs. structural integrity.

Surface Treatments: Paint, powder coating, or galvanization to enhance longevity.

Applications

1.Construction

Decorative cladding, ceilings, railings, and noise barriers for generator rooms.

2.Transport Infrastructure

Highway/railway soundwalls, subway ventilation grilles.

3.Industrial Machinery

Mining screens, equipment guards, and factory ventilation systems.

4.Agriculture

Greenhouse vents, livestock fencing, and crop drying racks.

Pricing Factors

Material: Galvanized/manganese steels cost more than cold-rolled.

Thickness & Size: Thicker/larger sheets increase price.

Complexity: Unique hole patterns or tight tolerances raise production costs.

Contact us for exact quotes with your specifications.

Why Choose Us?

As a trusted Chinese manufacturer, we deliver high-quality perforated metal solutions with fast turnaround. Our team collaborates closely with clients to optimize designs for cost and performance.

Process: Email details → Technical review → Quote within 48hrs.

Email: 342096438@qq.com