3. Applications

Galvanized perforated sheets are highly versatile and used in a wide range of industries:

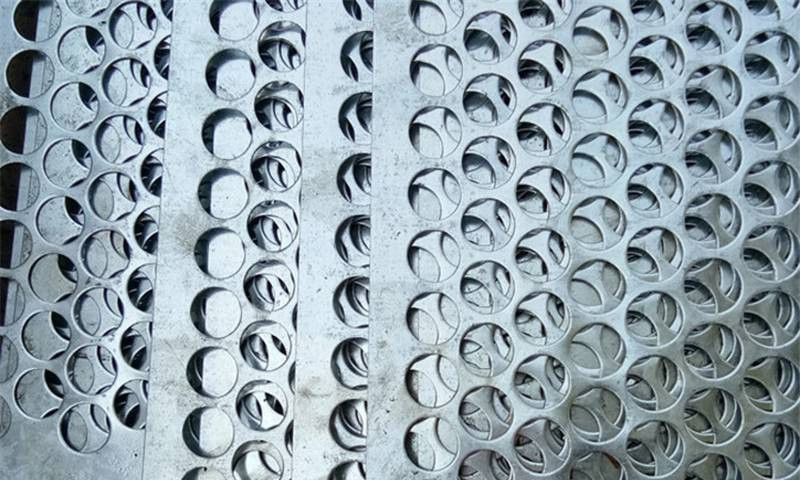

Architectural Decoration:

Used in facades, ceilings, partitions, and railings—offering both style and function.

Mechanical Equipment:

Commonly used as protective covers, filters, ventilation panels, and more.

Transportation Infrastructure:

Ideal for highway and railway noise barriers and anti-glare panels, improving safety.

Agriculture & Food Processing:

Applied in grain screening, drying systems, and ventilation to enhance productivity.

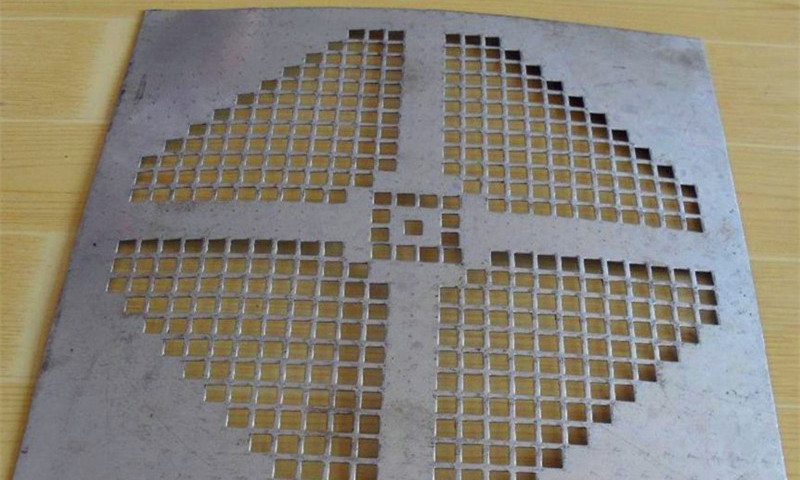

Furniture Manufacturing:

Modern furniture often incorporates perforated metal in chair backs, cabinet doors, etc., for added aesthetics.