Company Profile

We are a specialized perforated sheet manufacturer based in China, providing standard and custom perforated metal solutions to global clients. With advanced production technology, our products are widely used in architectural decoration, industrial filtration, and safety protection, exported to over 100 countries including Europe, North America, and Southeast Asia.

Product Range

1. By Material

Cold/Hot Rolled Steel Perforated Sheet: High-strength applications.

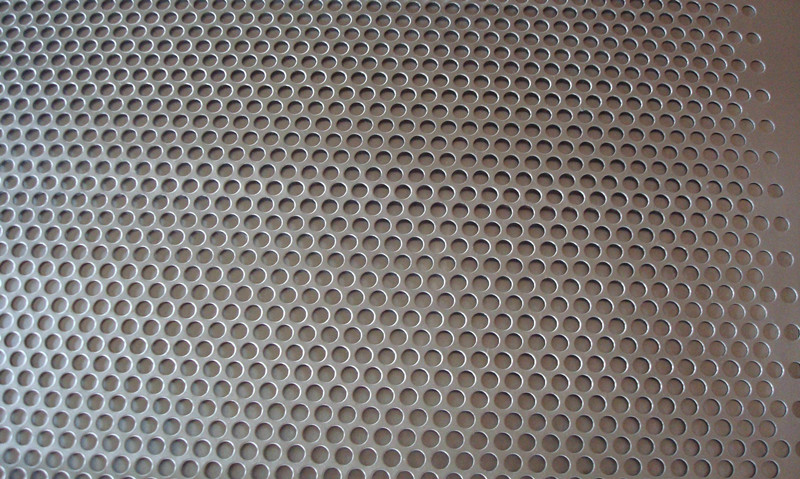

2. By Hole Pattern

Hole Size: 0.4mm–10mm

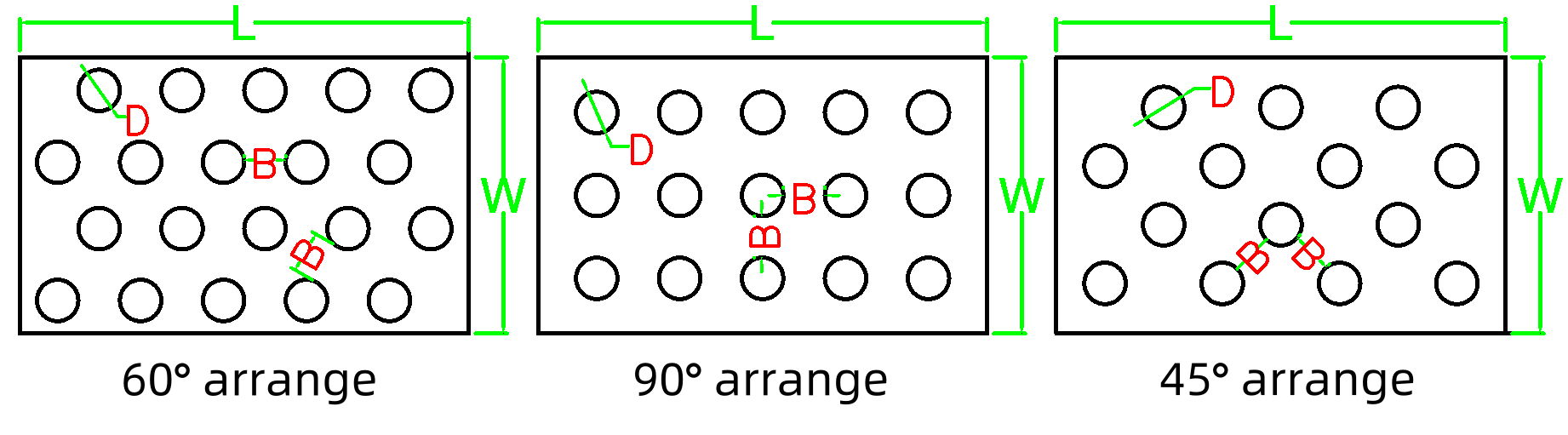

Arrangement: 60° staggered / 90° straight / 45° slanted

Applications: Building facades, speaker grilles.

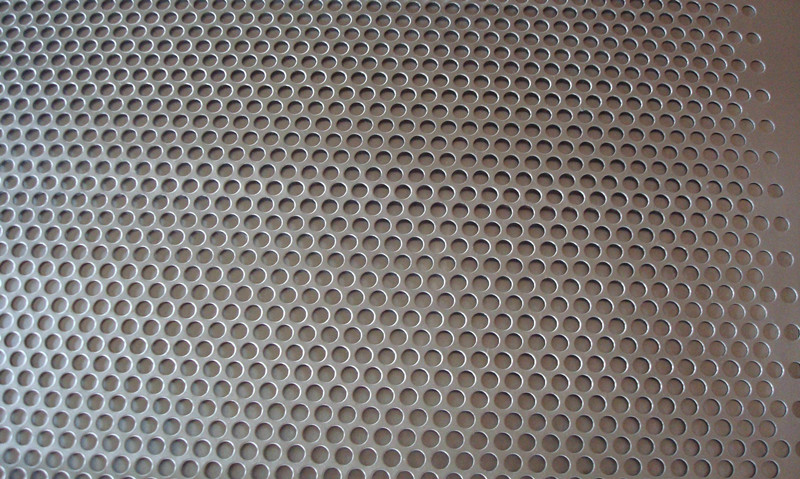

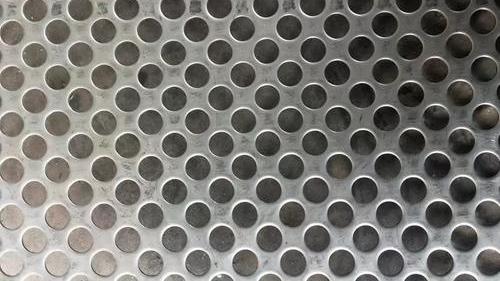

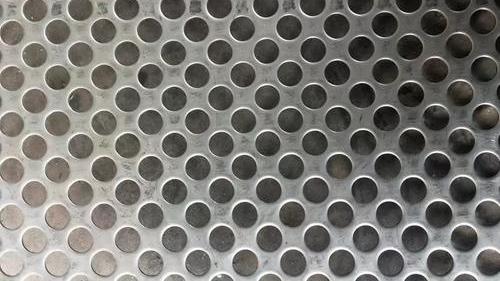

Display of Hole Pattern in Round Hole Perforated Sheet

60° Round Hole Perforated Sheet

90° Round Hole Perforated Sheet

45° Round Hole Perforated Sheet

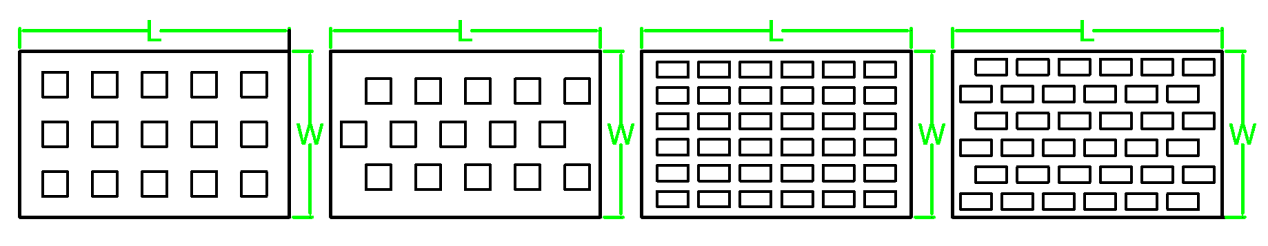

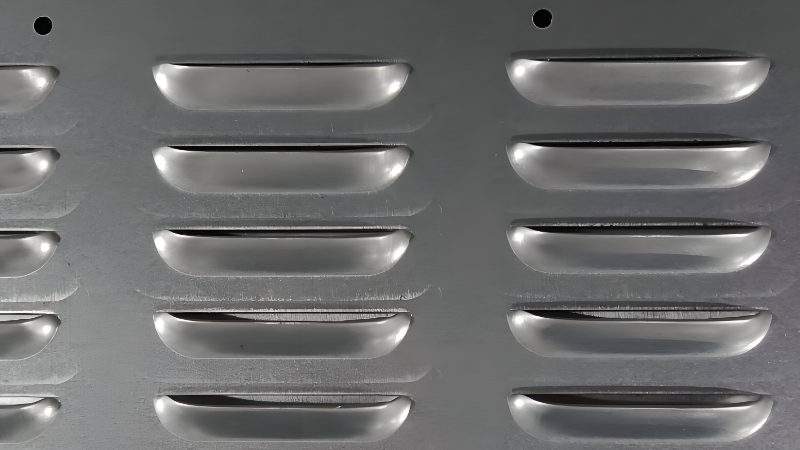

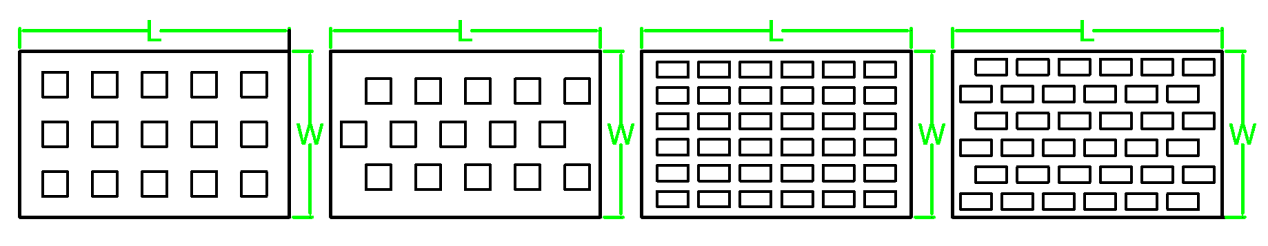

Sizes: 5×5mm to 100×100mm (custom rectangular holes available).

Applications: Screening machines, ventilation systems.

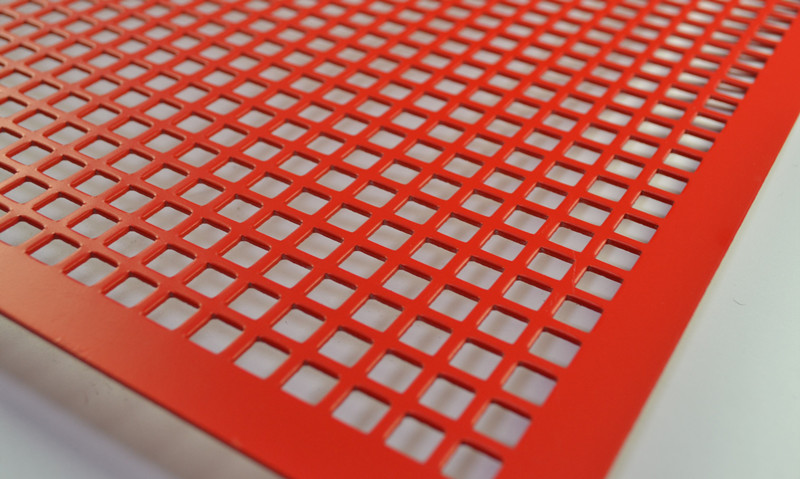

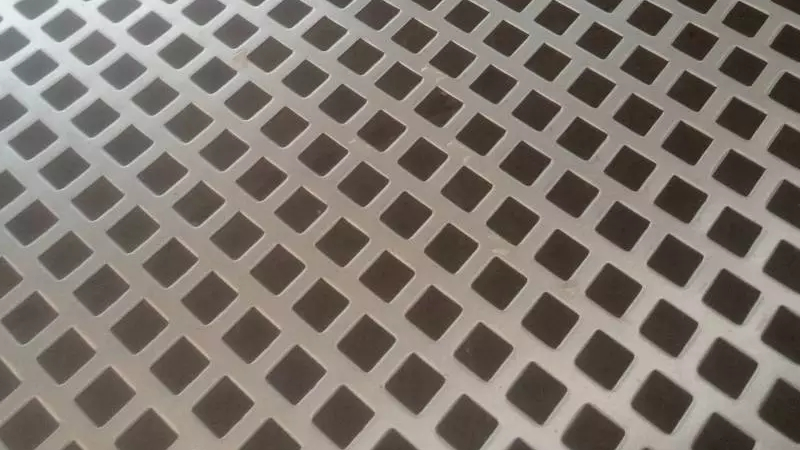

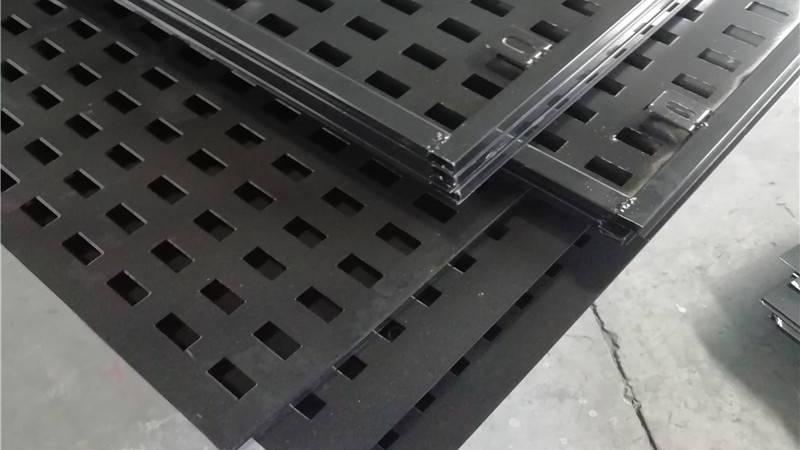

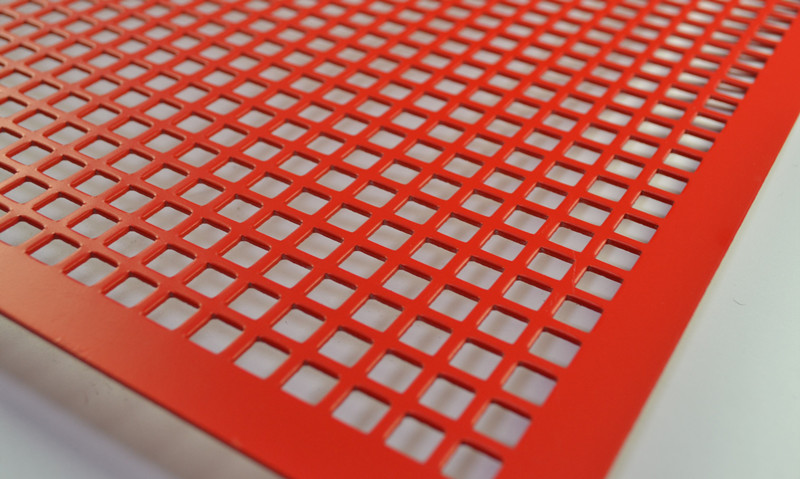

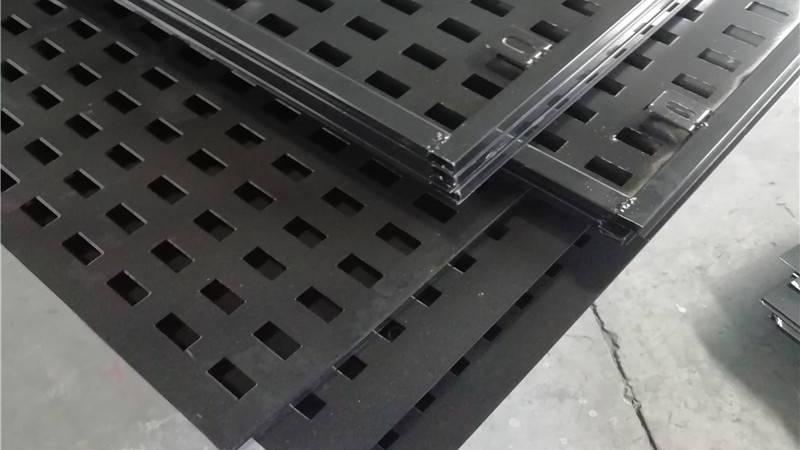

Display of Hole Pattern in Square Hole Perforated Sheets

Square hole perforated sheet

Square hole perforated sheet

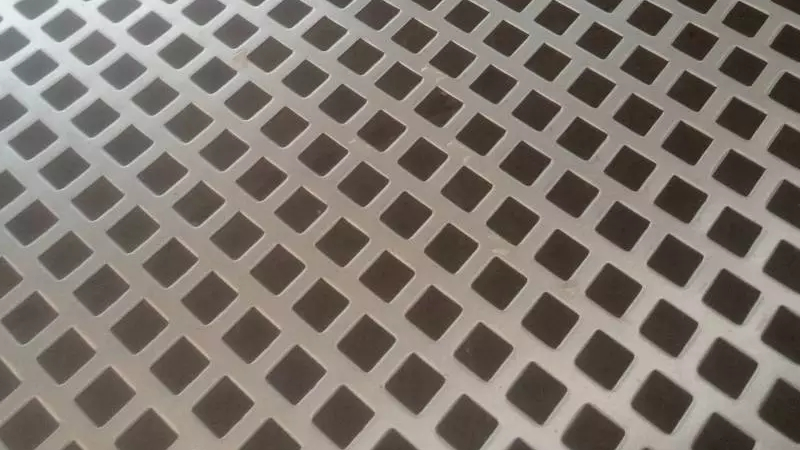

rectangular holes perforated sheet

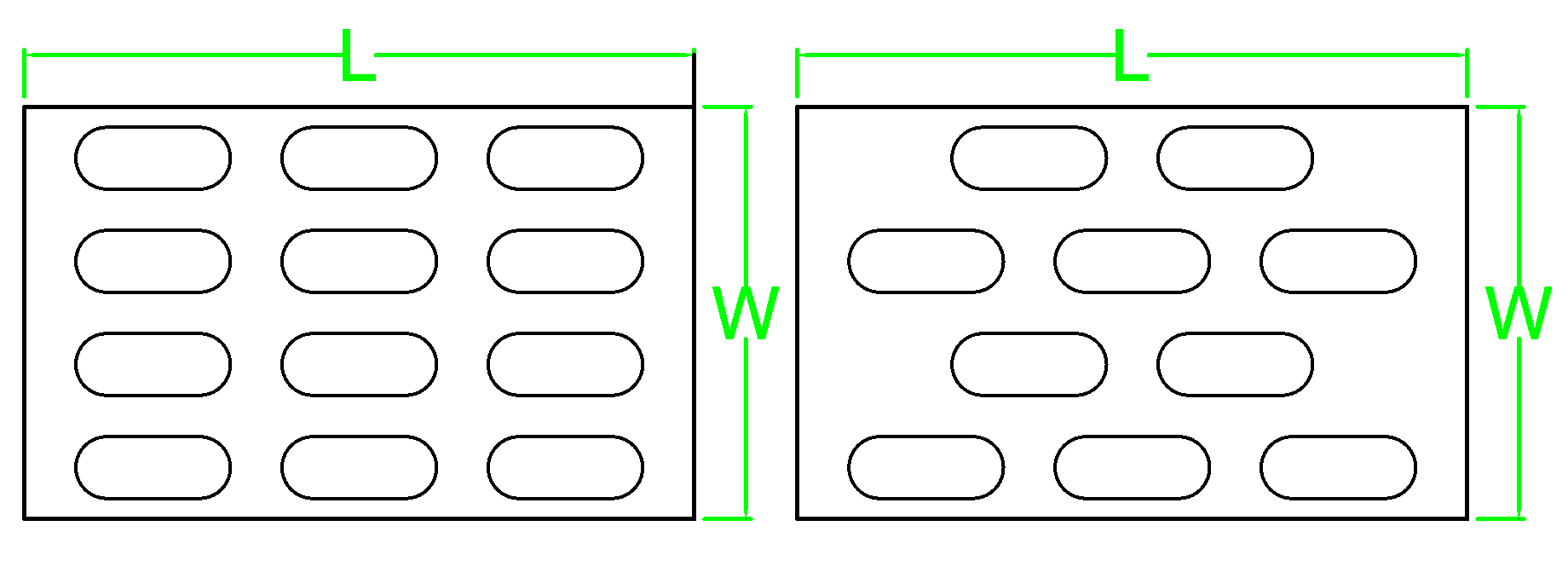

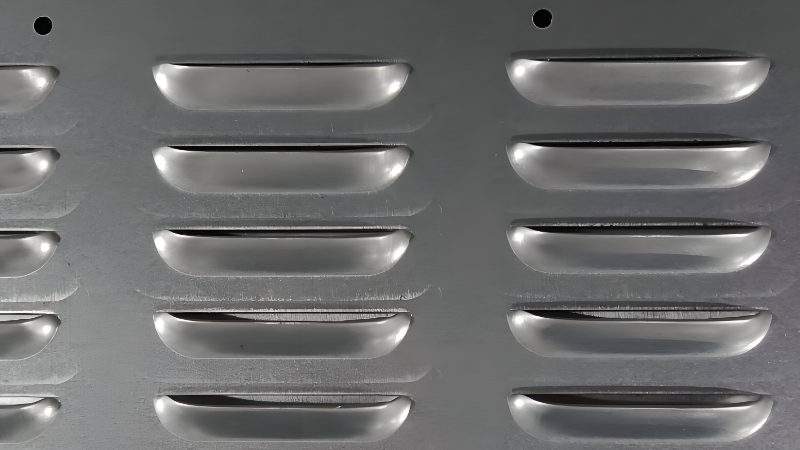

Dimensions: 2×3mm to 50×100mm (adjustable spacing).

Applications: Grain processing, conveyor belts.

slot perforated sheets Arrangement mode

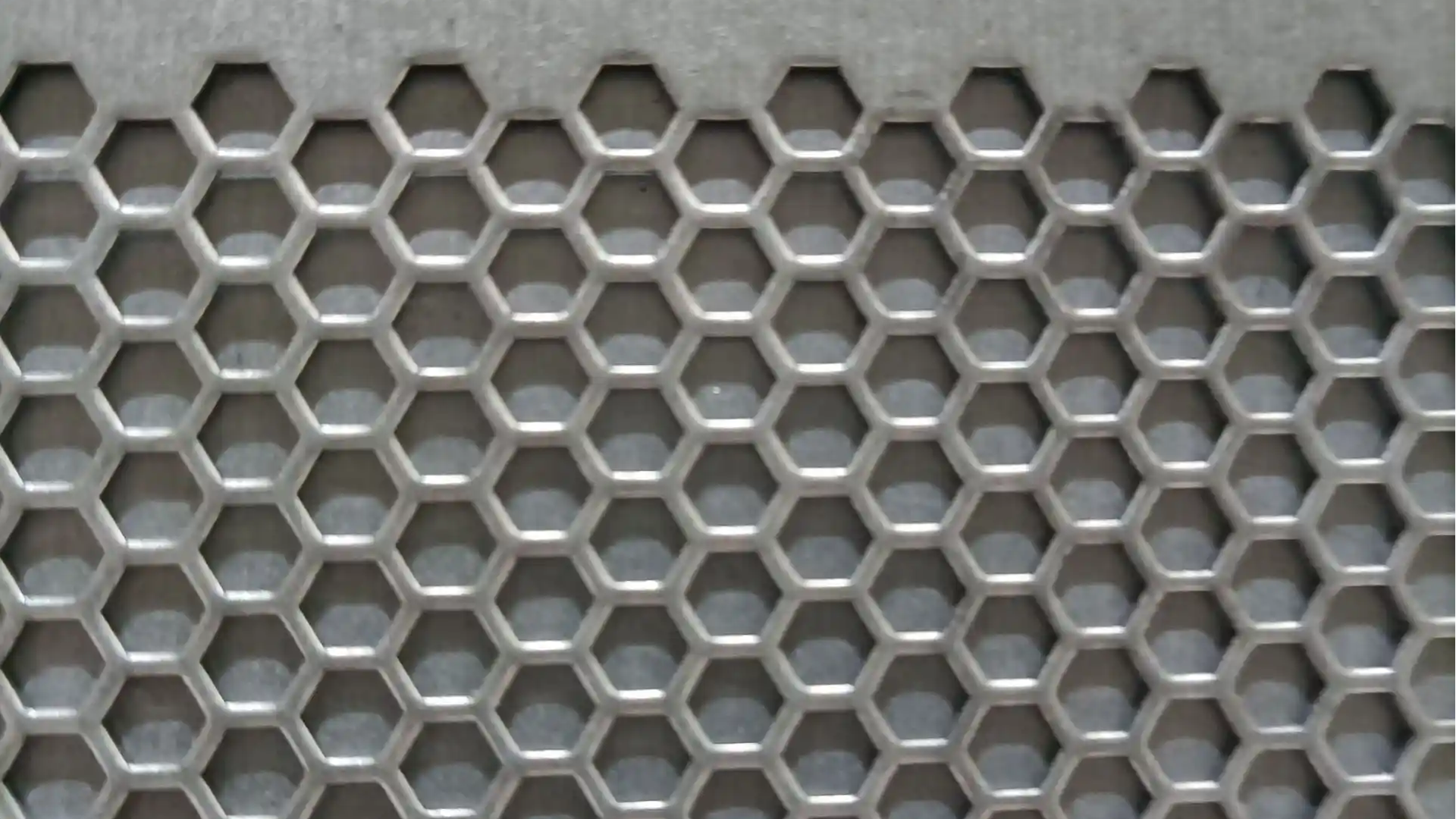

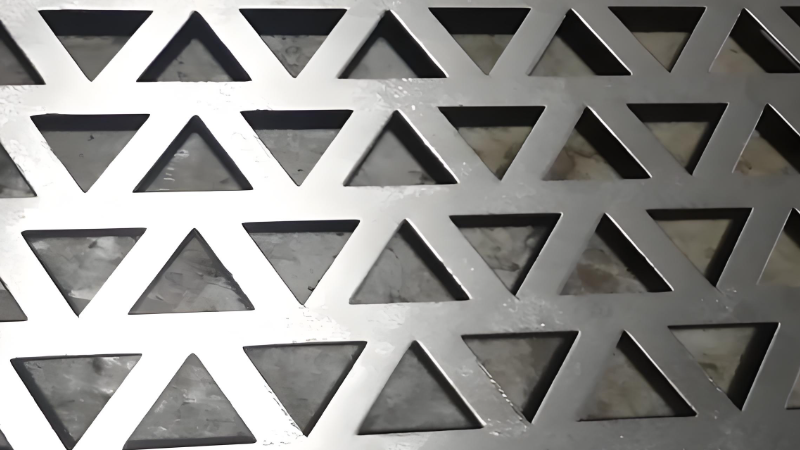

Special Patterns

Hexagonal, fish-scale, cross, triangular, diamond, or wave holes. Custom designs accepted (CAD files supported).

Customization Services

We tailor perforated metal sheets to your exact needs:

Technical Flexibility

Material Thickness: 0.3mm–50mm

Sheet Size: Max. 1500mm (width) × 4000mm (length); special sizes negotiable.

Surface Treatments: Powder coating, anodizing, electropolishing.

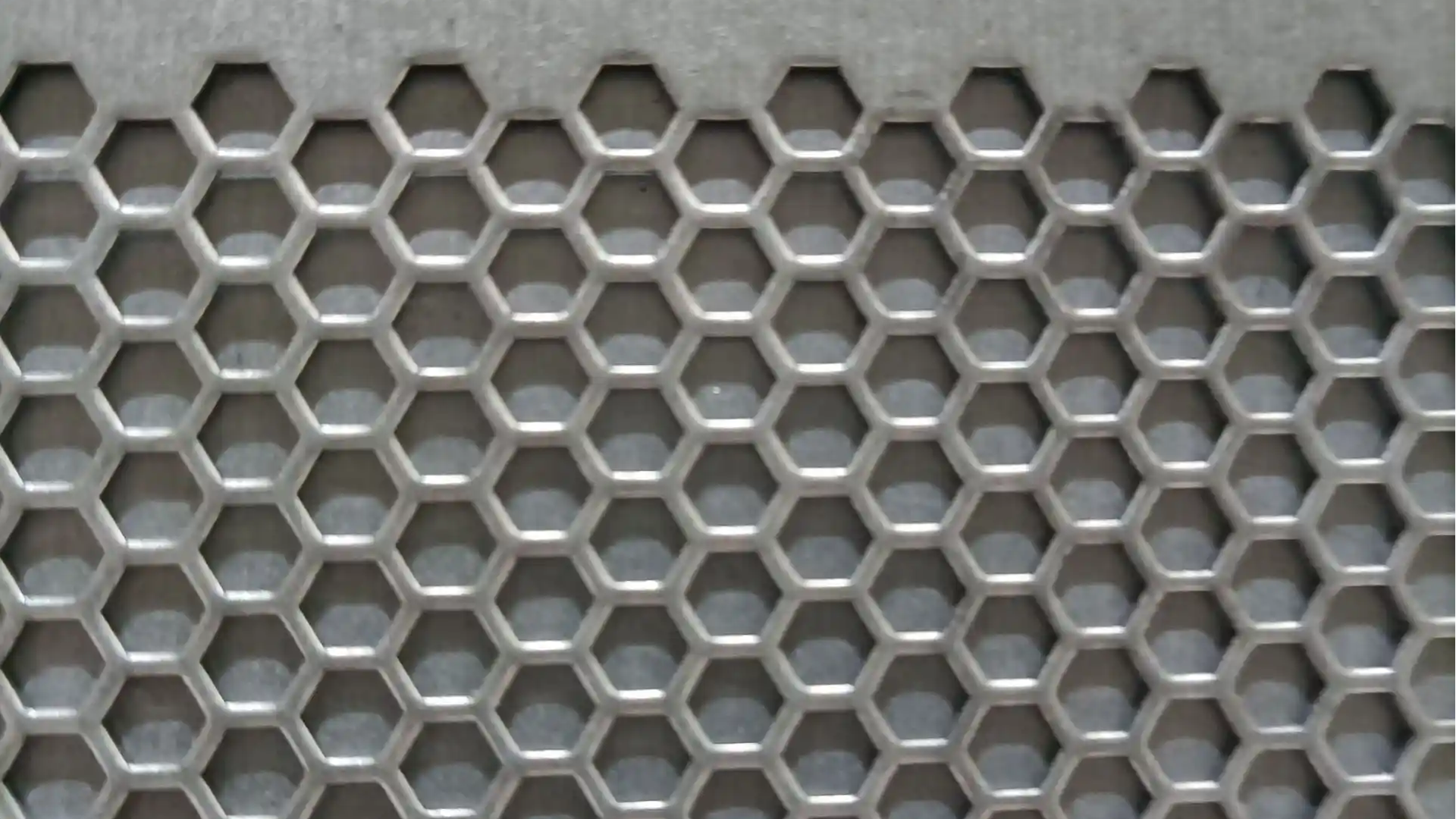

hexagonal holes perforated sheets

Production Advantages

Small-batch samples available.

Rush orders accepted (timeframe assessed case-by-case).

Custom packaging (anti-rust/scratch-proof).

Product Features

Precision: Hole tolerance ±0.1mm; open-area ratio 5%–70%.

Durability: Withstands -30°C to 300°C; select materials pass 500+ hours salt spray testing.

diamond-shaped holes perforated sheets

Industry Applications

Architecture: Sunshades, ceiling panels, subway station screens.

Industrial Filtration: Oil/gas sieves, food-grade screens, pharmaceutical vibratory sieves.

Safety: Machine guards, construction walkways, electrical substation fencing.

Quality Control

Raw material inspection.

In-process dimensional checks (30-min intervals).

Final pre-shipment audit.

Optional third-party testing reports.

crossed holes perforated sheets

Logistics & Support

Shipping: Ocean/air/express to global destinations.

Packaging: Anti-rust paper + wooden crates/steel frames.

After-Sales: 12-hour technical response; production documentation provided.

Contact Us

Email: 342096438@qq.com

Phone/WhatsApp/WeChat: +86 13165555855

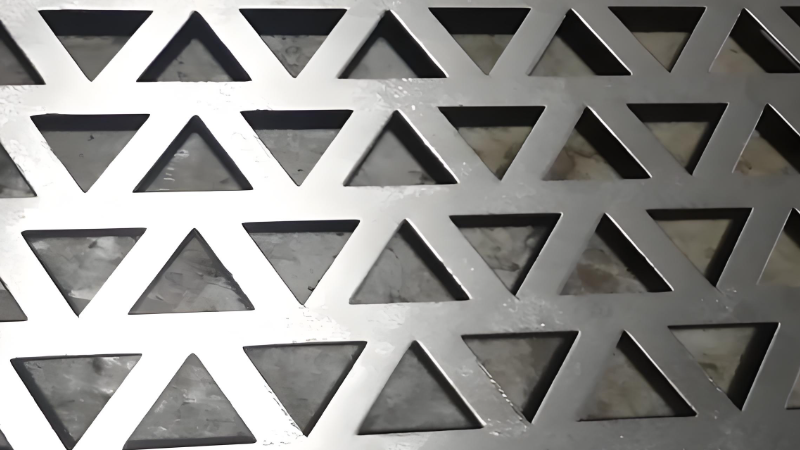

triangular holes perforated sheets

fish-scale-shaped holes perforated sheets

corrugated holes perforated sheets

Frequently Asked Questions (FAQ)