Precision Manufacturing Process

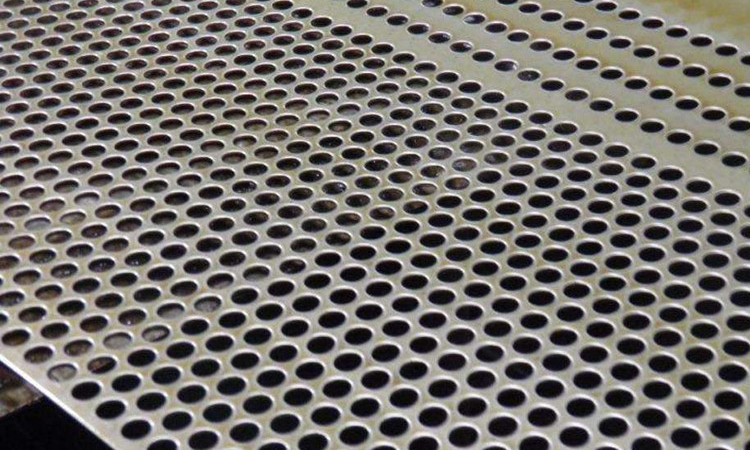

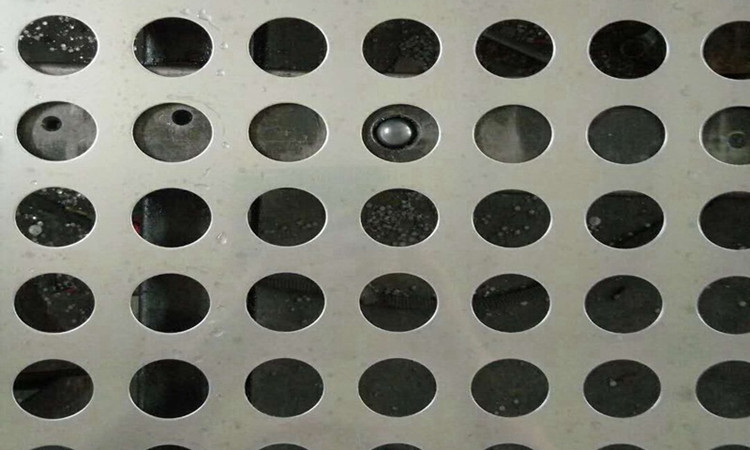

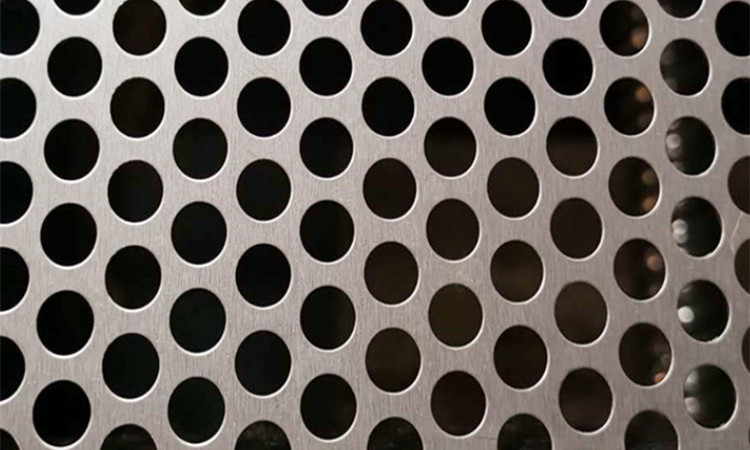

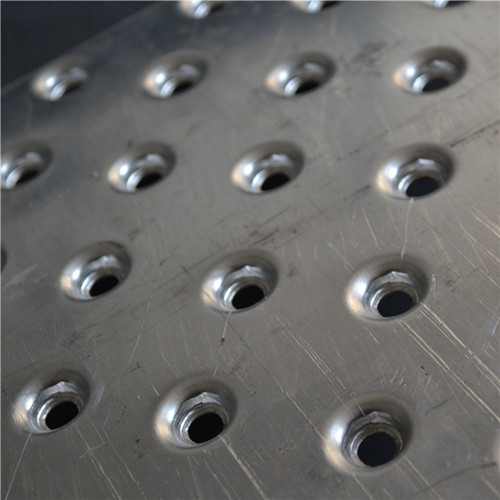

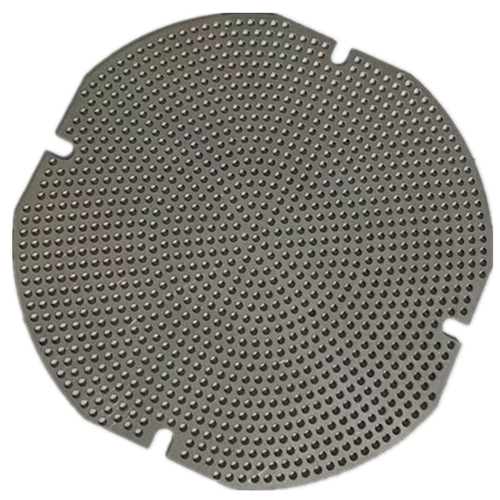

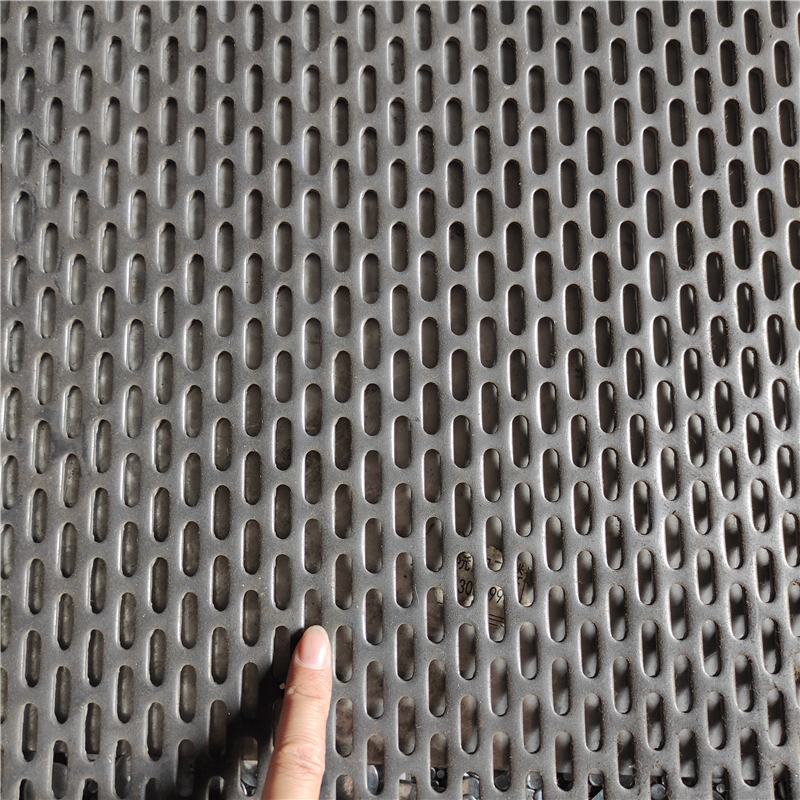

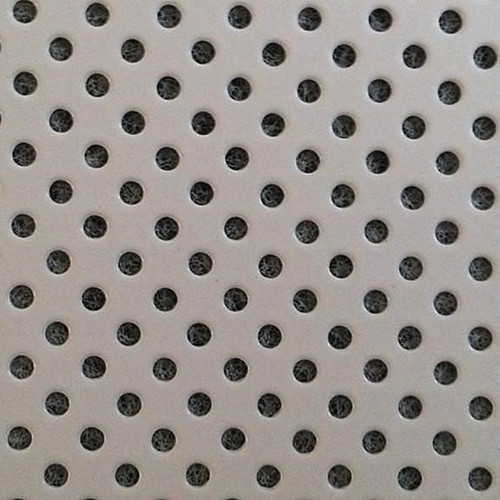

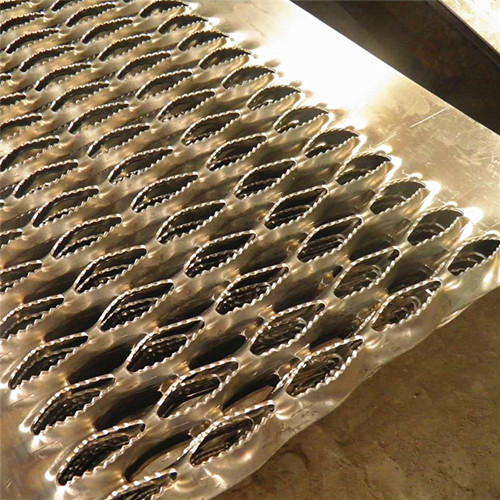

Accurate Hole Design: Custom molds on CNC punch presses guarantee uniform round holes with smooth edges.

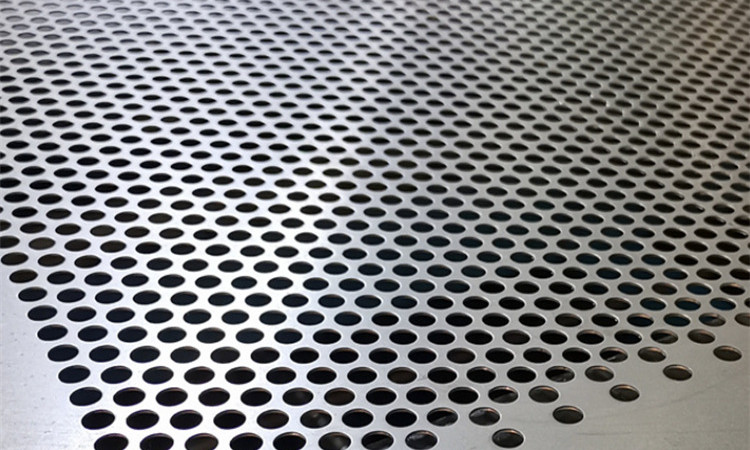

Flat Mesh Surface: Strict process controls ensure high flatness and structural integrity.

Flexible Customization: Supports various hole arrangements, such as straight or staggered rows.

Wide Application Areas

Construction and Decoration: Facade cladding, interior partitions, acoustic ceiling panels, railings, stair treads, ventilation grilles, and decorative screens.

Environmental and Industrial Use: Noise barriers for highways/railways, machine guards, filtration screens (e.g., grain, mining), hopper liners, and platform gratings.

Food and Kitchen Sector: Kitchen accessories (e.g., baskets, food covers, countertops), conveyor belts for processing lines, and display racks.

Agriculture and Horticulture: Greenhouse ventilation nets, seedling beds, and animal cages.

Other Fields: Speaker grilles, exhibition stands, furniture design, and automotive parts.

Customization Services – Tailored to Your Needs

As experts in non-standard solutions, we offer comprehensive services:

Hole Size: Custom apertures from 1mm to 300mm.

Hole Spacing: Customizable center-to-center distances based on strength requirements.

Plate Thickness: Processes 0.3mm to 20mm 304 stainless steel sheets.

Plate Dimensions: Standard sizes (e.g., 1000mm x 2000mm, 1220mm x 2440mm, 1500mm x 3000mm, or roll options like 1000mm x 20000mm). Non-standard sizes supported for widths ≥50mm to ≤1500mm and lengths ≥50mm to ≤4000mm.

Surface Finishes: Options include mill finish (NO.1/2B), brushed, mirror, sandblasted, or electropolished (subject to thickness and feasibility).

Special Shapes: Custom perforated plates based on drawings or samples.